Technical data

11..00 IINNTTRROODDUUCCTTIIOONN

1. The appliances incorporate a microprocessor based, fully

modul

a

ting air/g

as r

atio control system with direct burner

ignition. This provides a modulated heat output, with internal

frost protection provided as standard. The heat exchanger is

cons

t

ruct

ed from stainless steel encased in high temperature

polymer.

A combined circulating pump, automatic air vent assembly,

pressure gauge, safety valve and system expansion vessel are

included.

Isolation valves are fitted to the service connections.

The boiler

has a pump o

ver run feature therefore the central

heating system must include either a proprietary automatic

bypass valve or a radiator must be fitted with lock shield

valves. A separate CH expansion vessel is not required if the

total CH system content is less than 84 litres. However one is

required for systems with volumes greater than 84 litres; refer

t

o section 6.5. It

i

s r

ecommended tha

t

a drain cock is fitted at

the lowest point in the system.

66

© Dimple

x Boiler

s 2008

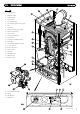

11..55 DDEESSCCRRIIPPTTIIOONN

RF room thermostats etc, are available as optional extras,

howe

v

er

if an e

xternal control is fitted the hole in the fascia

must be covered using the fascia blanking panel supplied (Part

No. 300635)

2. The boiler is designed for use on Natural Gas (G20). A

natural gas to propane conversion kit is available for each

Dimplex System Boiler.

3. The boiler is suitable for use only on fully pumped sealed

heating systems.

4. The boiler data badge gives details of the model, serial

number and Gas Council number and is situated on the inner

door panel. It is visible when the case front is removed. (Fig. 1)

5. The boiler model name and serial number are also shown on

the information label on the inside of the fascia. This is for

user reference.

6. The boiler is intended to be installed in residential /

commercial / light industrial E.M.C. environments on a

governed meter supply only.

7. The boiler must be installed with one of the purpose

designed flues such as the standard horizontal telescopic flue

kit, part no. 956120.

8.

AAllll ssyysstteemmss mmuusstt bbee tthhoorroouugghhllyy fflluusshheedd aanndd ttrreeaatteedd wwiitthh

iinnhhiibbiittoorr ((sseeee sseeccttiioonn 66..22))..

11..66 OOPPTTIIOONNAALL EEXXTTRRAASS

• Boiler

• Wall fixing jig

• T

emplates & ‘Quick Fit’ Guide

• Literature Pack

• Plugs and screws

11..77 PPAACCKK CCOONNTTEENNTTSS

11..44 SSAAFFEE MMAANNUUAALL HHAANNDDLLIINNGG

1. The boiler should be handled and lifted by two people.

Wear appropriate Personal Protection Equipment e.g. protective

gloves, safety footwear etc.

Plan your route to minimise the number of turns needed to

handle/lift the boiler.

2. Where possible transport the boiler using a sack truck or

other suitable trolley. Try to avoid steps, wet or slippery

surfaces, unlit areas etc. and take special care on ladders/into

lofts.

3. When handling or lifting always use safe techniques - keep

your back straight, bend your knees. Don’t twist - move your

feet, avoid bending forwards and sideways and keep the load

as close to your body as possible.

4. Asses the risks associated with handling and lifting

according to the conditions on site. If in doubt seek advice

before proceeding. Health and Safety is the responsibility of

everyone.