User guide

D-M-E CHILL VENT BY NGK Specification No. ME-080065-999(C)

VPS9999 Page 1 of 2

IMPORTANT SAFETY INFORMATION

BEFORE USING THIS PRODUCT

REFER TO IMPORTANT SAFETY INFORMATION AT MANUFACTURER’S WEBSITE:

http://www.ngkmetals.com/index.cfm/m/19

ADDITIONAL INFORMATION MAY BE FOUND AT:

http://www.osha.gov/dts/hib/hib_data/hib19990902.html

READ ALL INSTRUCTIONS BEFORE HANDLING THIS PRODUCT INCLUDING THE MSDS.

THIS INSTRUCTION IS TO BE PASSED ALONG TO THE END USER.

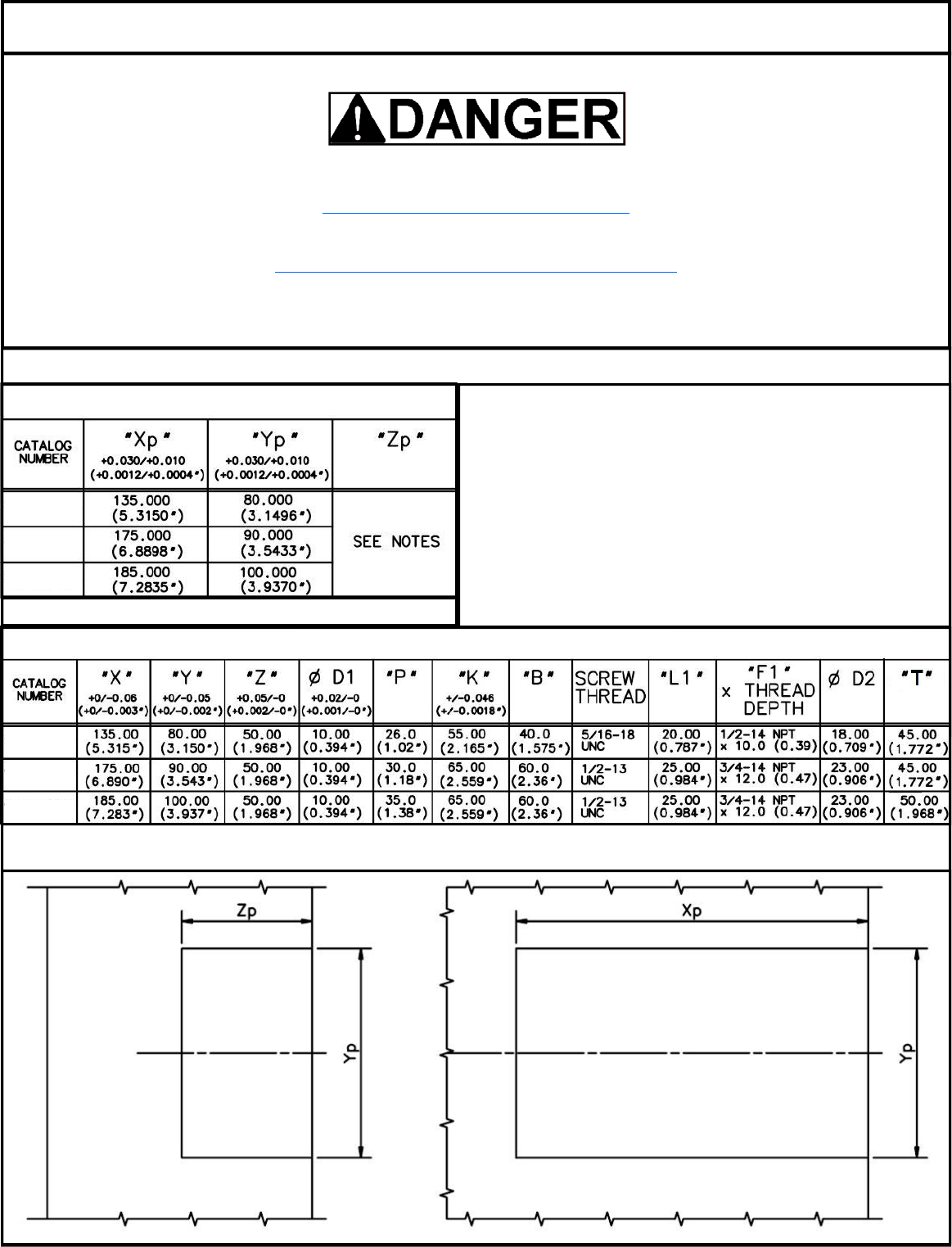

CHILL VENT POCKET DETAIL

INSTALLATION INSTRUCTIONS

Dimensions shown are in millimeters (inches).

Pocket Notes:

•

Perpendicularity and Parallelism of pockets must be

machined such that Chill Vent insert halves mate after

installation without gaps between insert halves.

• Corner radii of Chill Vent insert pockets are to be

machined to suit dimensions shown. Toolmaker is

responsible for modification of corner radii of Chill

Vent Inserts to accommodate machining method used.

• All surfaces of pocket to have a surface finish no

greater than 0.8 μm (micrometers). Check for burrs.

• For Zp, use shim pack to accommodate flushness.

Flushness tolerance must be +0.05/-0 (+0.002/-0”).

POCKET DIMENSIONS

VSCL7US

VLCL7US

VECL7US

65.00

(2.559”)

VSCL7US

VLCL7US

VECL7US

COMPONENT INSERT DIMENSIONS

Example Pocket for one half of Chill Vent

Insert Assembly. Clearance slots for

cooling lines and pipe fittings are not

shown. Key slot, tap counter-bores and

installation for ejector pin not shown.

Toolmaker is responsible to modify

installation to accommodate the

features listed above.