Technical data

XP95 Optical Smoke Detector s Part Number 55000-600/620/660

OPERATING

PRINCIPLES

The XP95 optical detector

uses the same outer case

as the ionisation smoke

detector and is distinguished

by the indicator LED which

is clear in standby and red in

alarm. Within the case is a

printed circuit board which

on one side has the light

proof labyrinth chamber with

integral gauze surrounding

the optical measuring system

and on the other the address

capture, signal processing and

communications electronics.

An infrared light emitting

diode within its collimator is

arranged at an obtuse angle to

the photo-diode. The photo-

diode has an integral daylight-

blocking filter.

The IR LED emits a burst of

collimated light every second.

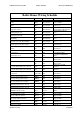

Fig.7 Top section - XP95 Optical Smoke Detector

In clear air the photo-diode

receives no light directly from

the IR LED because of the

angular arrangement and

the dual mask. When smoke

enters the chamber it scatters

photons from the emitter IR

LED onto the photo-diode

in an amount related to the

smoke characteristics and

density. The photo-diode

signal is processed by the

optical ASIC and passed to

the A/D converter on the

communications ASIC ready

for transmission when the

device is interrogated.

ELECTRICAL

DESCRIPTION

The detector is designed to be

connected to a two wire loop

circuit carrying both data and

a 17V to 28V dc supply. The

detector is connected to the

XP95 OPTICAL SMOKE DETECTOR

incoming and outgoing supply

via terminals L1 and L2 in the

mounting base. A remote

LED indicator requiring not

more than 4mA at 5V may

be connected between the

+R and -R terminals. An earth

connection terminal is also

provided.

When the device is energised

the ASICs regulate the

flow of power and control

the data processing. The

optical ASIC is controlled by

the communications ASIC

and pulses the IR LED. The

signal from the photo-diode

is processed by the optical

ASIC and transferred to the

communications ASIC where it

is then stored. When smoke

enters the chamber the

photo-diode signal increases.

The information to the A/D

converter is updated once

per second or when either

the monitor or the preceding

address is interrogated.

Whenever the device is

interrogated this data is sent

to the control equipment.

EN54 threshold alarm levels

are calibrated within the

processing ASIC. If the device

is not addressed within one

second of its last polling and

the analogue value is greater

than the EN54 alarm level the

alarm flag is initiated and the

device address is added to the

data stream every 32 polling

cycles from its last polling

for the duration of the alarm

level condition, except when

the alarming device is being

interrogated. This can provide

a location identified alarm

from any device on the loop

in approximately two seconds.

The detector is calibrated

to give an analogue value

of 25±7 counts in clean air.

This value increases with

smoke density. A count of

55 corresponds to the EN54

alarm sensitivity level. See

Fig. 9.

ENVIRONMENTAL

CHARACTERISTICS

The XP95 optical smoke

detector is unaffected by

wind or atmospheric pressure

and operates over the

temperature range -20°C to

+60°C. See Fig. 10.

page

9