Installation Guide Owner's manual

Table Of Contents

- Cover

- Copyright

- Table of Contents

- Warnings

- 1 - Specifications and Operating Requirements

- 2 - Stationary Dyno Installation

- 3 - 4WD Dyno Installation

- Unpacking and Inspecting the Dyno

- Track Assembly

- Dyno Installation

- Cable Routing

- Identifying the Cables

- Routing the Cables—Without the Eddy Current Brakes

- Wiring the Breakout Board—Without the Eddy Current Brakes

- Routing the Cables—With One Eddy Current Brake

- Wiring the Breakout Board—With One Eddy Current Brake

- Routing the Cables—With Two Eddy Current Brakes

- Wiring the Advanced Breakout Board—With Two Eddy Current Brakes

- Hydraulic Movement Installation

- Air Can Sleeve

- 4WD Dyno Movement Test

- Bridge Installation—Stationary Dyno

- Bridge Installation—4WD Dyno

- Deck Installation

- Logo Panel Installation

- 4 - Eddy Current Brake Installation

- Eddy Current Brake Installation

- Before Installing the Eddy Current Brake: Verify Optimal Brake Cooling

- Before Installing the Eddy Current Brake: Verify Mounting Holes

- Unpacking the Eddy Current Brake

- Installing the Temperature Sensor

- Installing the Bearing, Splined Shaft, and Driveline Assembly

- Installing the Eddy Current Brake

- Installing the Load Cell

- Installing the Front and Rear Brake Covers and Theta Controller

- Torque Module Installation

- Load Cell Calibration

- Eddy Current Brake Installation

- 5 - Side Deck Assembly Installation

- 6 - Basic Dyno Operation

- A - Red Head Anchor Installation

- B - Power Requirements and Installation

- C - Stationary Dyno Upgrade

- D - Bridge Extension Assembly

- E - Interface Roller Assembly Installation

- F - Torque Values

- Index

Above Ground Model 424x/424xLC

2

Automotive Dynamometer Installation Guide

APPENDIX D

Bridge Extension Installation

D-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

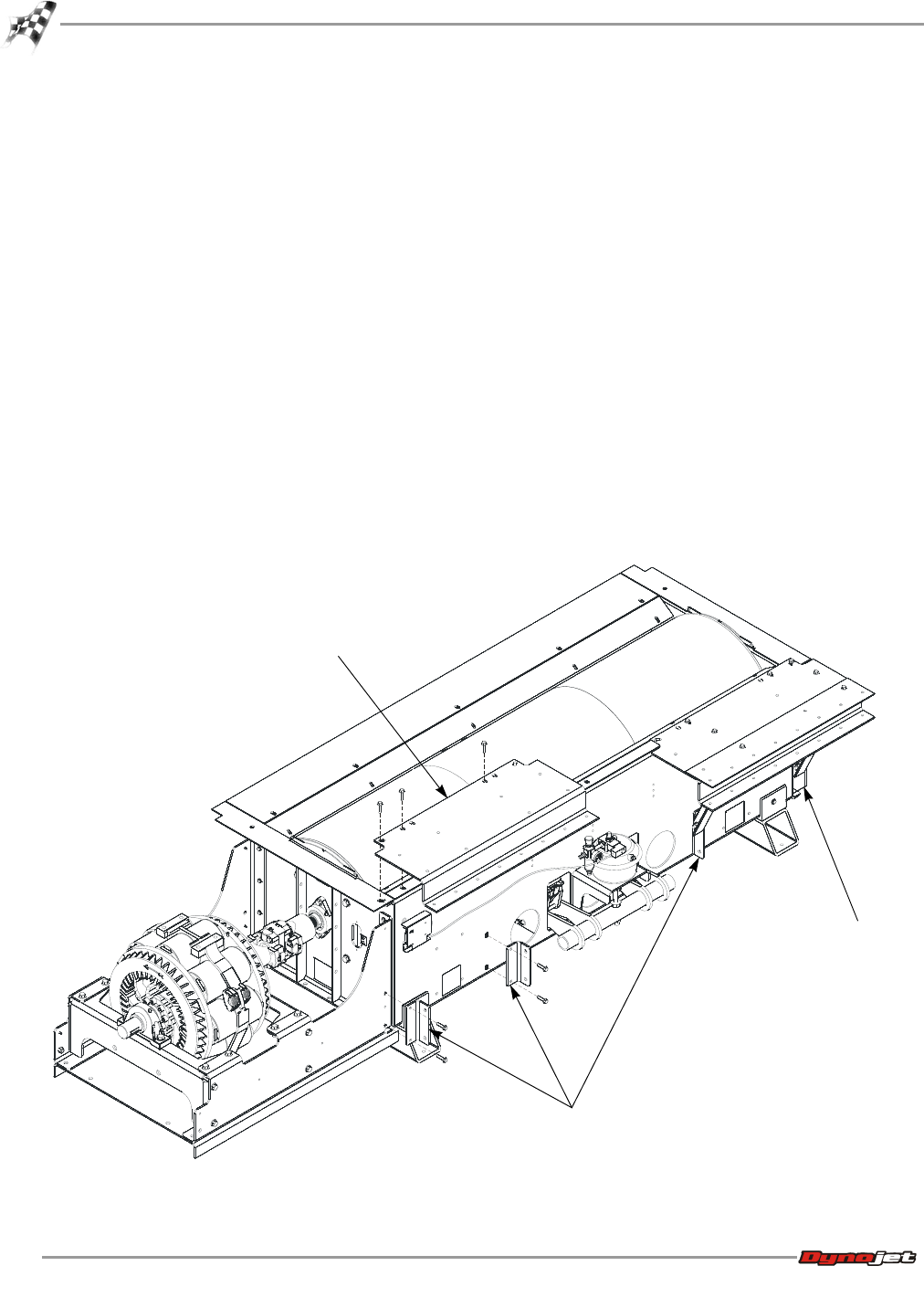

BRIDGE EXTENSION INSTALLATION

The optional bridge extension assembly (P/N 61119183) is used to extend the bridge

range from an 88-130 inch wheel base to a 98-140 inch wheel base.

Note: The Linx option can not be used with the extended wheel base.

1 Secure the extended runner mount (z-shaped bracket) to the drum guard using

three 3/8 x 1.5-inch flange hex allen bolts.

Note: The extended runner mounts used with the bridge extension are longer

than the standard runner mounts. Be sure to use the correct runner mounts.

2 Install the two inner brace mounts to the dyno using two 3/8 x 1.5-inch flange

head bolts each.

3 Secure the outer brace mount to the side of the dyno without the eddy current

brake using two 3/8 x 1.5-inch flange head bolts each.

4 Secure the remaining inner brace mount to the eddy current brake using two

3/8 x 1.5-inch flange head bolts and two 3/8-inch nylock nuts each.

Note: If you do not have an eddy current brake, you will use an outer brace

mount. Secure this directly to the dyno using the same hardware. Refer to Figure

D-2 on page D-3. In this case, there will be one left over inner brace mount.

Figure D-1: Install the Extended Runner Mount and Brace Mount

AD166

extended runner

mount

outer brace

mount

inner brace

mount