Installation Guide Owner's manual

Table Of Contents

- Cover

- Copyright

- Table of Contents

- Warnings

- 1 - Specifications and Operating Requirements

- 2 - Stationary Dyno Installation

- 3 - 4WD Dyno Installation

- Unpacking and Inspecting the Dyno

- Track Assembly

- Dyno Installation

- Cable Routing

- Identifying the Cables

- Routing the Cables—Without the Eddy Current Brakes

- Wiring the Breakout Board—Without the Eddy Current Brakes

- Routing the Cables—With One Eddy Current Brake

- Wiring the Breakout Board—With One Eddy Current Brake

- Routing the Cables—With Two Eddy Current Brakes

- Wiring the Advanced Breakout Board—With Two Eddy Current Brakes

- Hydraulic Movement Installation

- Air Can Sleeve

- 4WD Dyno Movement Test

- Bridge Installation—Stationary Dyno

- Bridge Installation—4WD Dyno

- Deck Installation

- Logo Panel Installation

- 4 - Eddy Current Brake Installation

- Eddy Current Brake Installation

- Before Installing the Eddy Current Brake: Verify Optimal Brake Cooling

- Before Installing the Eddy Current Brake: Verify Mounting Holes

- Unpacking the Eddy Current Brake

- Installing the Temperature Sensor

- Installing the Bearing, Splined Shaft, and Driveline Assembly

- Installing the Eddy Current Brake

- Installing the Load Cell

- Installing the Front and Rear Brake Covers and Theta Controller

- Torque Module Installation

- Load Cell Calibration

- Eddy Current Brake Installation

- 5 - Side Deck Assembly Installation

- 6 - Basic Dyno Operation

- A - Red Head Anchor Installation

- B - Power Requirements and Installation

- C - Stationary Dyno Upgrade

- D - Bridge Extension Assembly

- E - Interface Roller Assembly Installation

- F - Torque Values

- Index

STATIONARY DYNO INSTALLATION

Dyno Installation

Version 8 Above Ground Model 424x/424xLC

2

Automotive Dynamometer Installation Guide

2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DYNO INSTALLATION

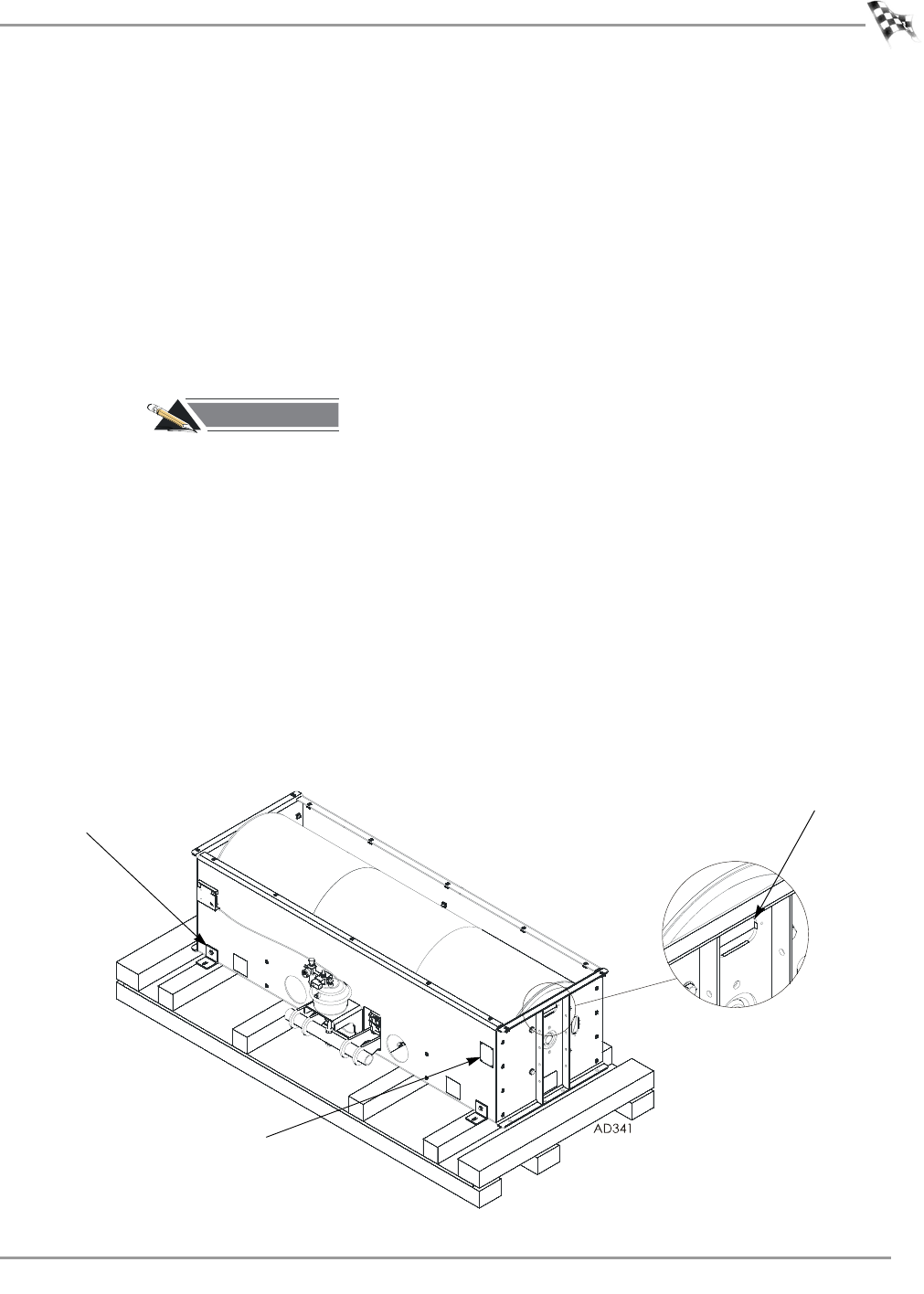

This section will walk you through removing the dyno from the crate and installing

the dyno in front of your lift. Refer to Appendix C for instructions on upgrading an

existing dyno.

REMOVING THE DYNO FROM THE CRATE

You will need to provide equipment capable of lifting a minimum of 2,114 kg

(4,660 lb.) to lift the dyno off the crate and into position in your dyno room. You will

also need a pair of straps capable of supporting the same weight. Dynojet

recommends using two 2-inch x 6-foot single loop style straps. Refer to “Forklift

Requirements” on page 1-7.

#

RECORD

Be sure you record the dynamometer number on the inside cover of this

manual.

1 Remove the crate braces that support the top portion of the crate.

2 Remove the four lag bolts and washers securing the dyno to the crate base using a

9/16-inch socket, open or box end wrench.

3 Remove and set aside the four flange bolts securing the crate feet to the dyno.

4 Route the loop strap through the opening in the dyno frame and through itself.

Pull the strap tight. Do this on each side of the dyno frame.

5 Push the forklift forks together.

6 Place each loop strap over both forks.

Note: The straps must be the same length and meet in the middle. Verify each

loop strap is over both forks to prevent the forks from being pulled apart.

7 Using the forklift, carefully lift the dyno off the crate and move it into position in

your dyno room.

Figure 2-1: Loop Strap Placement

place strap through

opening in dyno frame

dyno number

remove feet

set aside bolts