Installation Guide Owner's manual

Table Of Contents

- Cover

- Copyright

- Table of Contents

- Warnings

- 1 - Specifications and Operating Requirements

- 2 - Stationary Dyno Installation

- 3 - 4WD Dyno Installation

- Unpacking and Inspecting the Dyno

- Track Assembly

- Dyno Installation

- Cable Routing

- Identifying the Cables

- Routing the Cables—Without the Eddy Current Brakes

- Wiring the Breakout Board—Without the Eddy Current Brakes

- Routing the Cables—With One Eddy Current Brake

- Wiring the Breakout Board—With One Eddy Current Brake

- Routing the Cables—With Two Eddy Current Brakes

- Wiring the Advanced Breakout Board—With Two Eddy Current Brakes

- Hydraulic Movement Installation

- Air Can Sleeve

- 4WD Dyno Movement Test

- Bridge Installation—Stationary Dyno

- Bridge Installation—4WD Dyno

- Deck Installation

- Logo Panel Installation

- 4 - Eddy Current Brake Installation

- Eddy Current Brake Installation

- Before Installing the Eddy Current Brake: Verify Optimal Brake Cooling

- Before Installing the Eddy Current Brake: Verify Mounting Holes

- Unpacking the Eddy Current Brake

- Installing the Temperature Sensor

- Installing the Bearing, Splined Shaft, and Driveline Assembly

- Installing the Eddy Current Brake

- Installing the Load Cell

- Installing the Front and Rear Brake Covers and Theta Controller

- Torque Module Installation

- Load Cell Calibration

- Eddy Current Brake Installation

- 5 - Side Deck Assembly Installation

- 6 - Basic Dyno Operation

- A - Red Head Anchor Installation

- B - Power Requirements and Installation

- C - Stationary Dyno Upgrade

- D - Bridge Extension Assembly

- E - Interface Roller Assembly Installation

- F - Torque Values

- Index

Above Ground Model 424x/424xLC

2

Automotive Dynamometer Installation Guide

CHAPTER 2

Dyno Installation

2-12

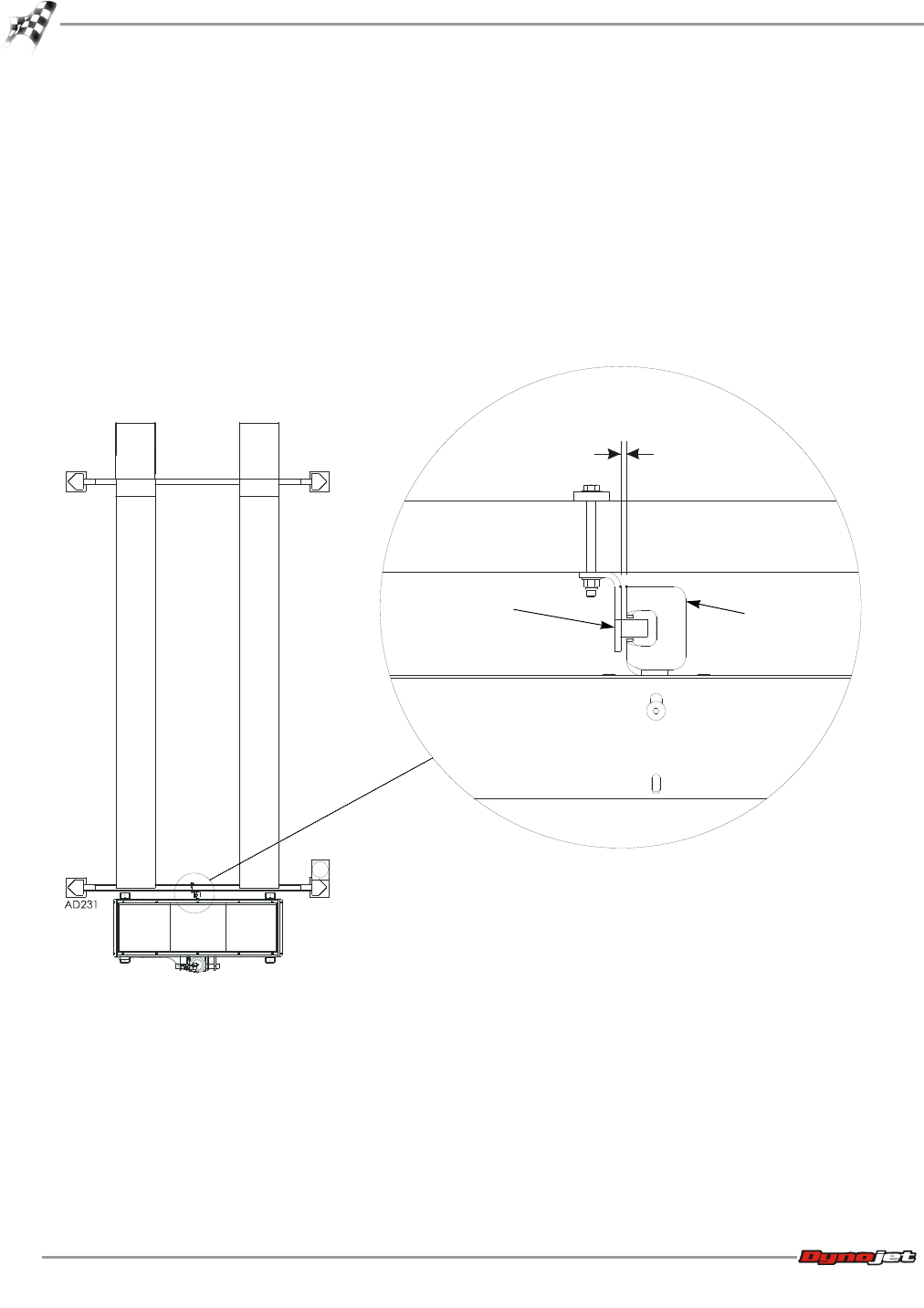

5 Verify the interface guide clears the interface bracket by 1/8-inch to 1/4-inch as

shown in Figure 2-6.

6 Slide the interface guide up until the bottom bolt touches the cross member.

Lower the top bolt down in the slots until it touches the cross member.

7 Tighten the hardware securing the interface guide to the lift cross member.

Note: The lower and upper interface guide mounting bolts should touch the lift

cross member.

8 Raise and lower the lift several times to make sure that the interface guide is

working smoothly. Adjust the interface guide if needed.

9 Verify the lift can be lowered down to floor level.

Figure 2-6: Verify Distance Between Interface Guide and Interface Bracket

interface guide on

cross member

interface bracket

on dyno

0.125" to .250"