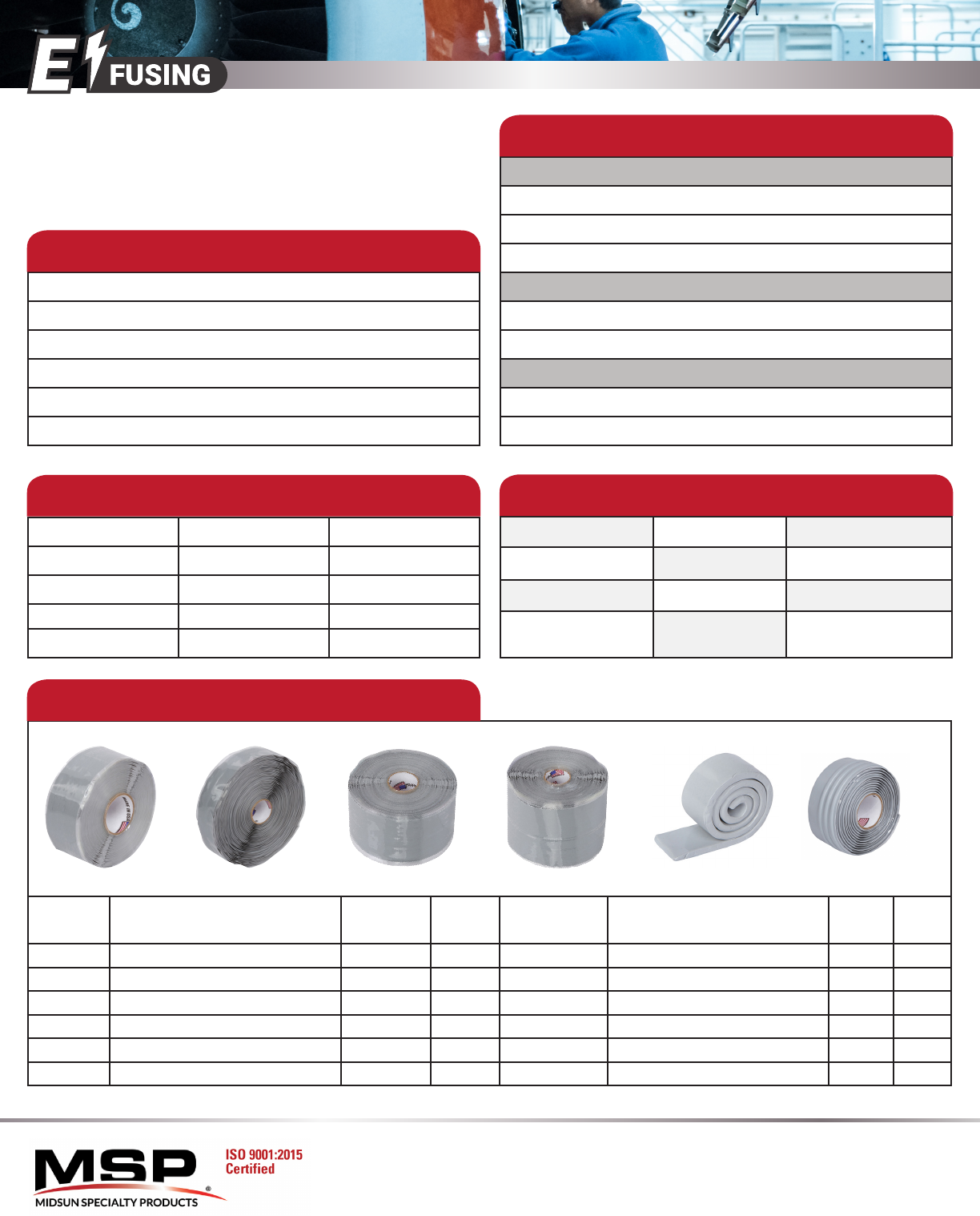

Comparison Chart

Part

Number

Description

Width

inch / mm

Length

ft / m

Thickness

inch / mm

Color / Type / Prole / Guideline

Flame

Resist*

Case

Qty

E112-010 112 Silicone Electrical Tape 1.00 / 25.4 30 / 9.1 0.012 / 0.304 Gray / I / Rectangular / Red Yes 12

E140-010 140 Silicone Sealing Tape 1.00 / 25.4 36 / 11 0.040 / 1.000 Gray / II / Triangular / Red Yes 12

E220-010 220 Wide Silicone Electrical Tape 2.00 / 50.8 36 / 11 0.020 / 0.508 Gray / I / Rectangular / Red Yes 6

E330-010 330 Wide Silicone Sealing Tape 3.00 / 76.2 36 / 11 0.030 / 0.760 Gray / II / Triangular / Red Yes 6

E900-010 900 Moldable Silicone Putty 1.00 / 25.4 1.5 / .45 0.125 / 3.175 Gray / NA / Flat / None Yes 12

E903-010 903 Insulating Silicone Grip 1.25 / 31.8 5 / 1.5 0.067 / 1.700 Gray / NA / Ridge Grip / None Yes 12

freight Prepaid in USA with 1 case minimum order

Surcharge may apply for HI, AK, and international

terms Initial PO Prepay by CC. Reorders - Net 30

lead time 1-3 weeks from order conrmation

returns RMA required for defective merchandise

distributor Contact your salesperson for pricing

378 Four Rod Rd. Berlin, CT 06037 USA

email sales@midsunsp.com

tel 888-866-8273 | web midsunsp.com

ofce 860-378-0111 | fax 860-378-0113

E/Fusing silicone tapes and accessories are formulated

from high performance silicone rubber for use in extreme

environments. They self-bond and seal to form a Class H

insulating protective layer with excellent resilience to elements

and harsh conditions.

Stretches 300% and forms around irregular shapes

Bonds using cross-link technology to fuse into a solid layer

Contains no glues or adhesives, leaves no residue, easily removable

Withstands temperatures from -65°F to 500°F (-54°C to 260°C)

Insulates at least 400V / mil. Meets and exceeds UL510

Naturally resists, UV, oil, salt, chemicals, ozone, moisture and corona

Hardness 50 Shore Durometer

Bond Strength ASTM D-2148 2 psi

Water Absorption 6251 3 % By Weight

Tensile Strength ASTM D-412 750 psi

Volume Resistivity ASTM D-257 3 x 10

14

OHM/CM

Maintenance

• Vibration dampening, scratch resistance and increase traction

• Wire harness, cable bundling, identication and organization

• Terminate wires, splice wrap, thermal and electrical insulation

Repair

• Mitigate leak damage during emergencies / Create custom O-rings

• Repair/restore deteriorated handles, levers and grips

Operation

• Stop-off masking, protect surfaces from UV and contamination

• Create barrier to protect critical equipment from wildlife tampering

Coil and Motor Leads Pipes and Fittings Underground Cable

Slurry and Waste Pipe Electrical Bus Bar Flexible Hose & Conduit

Coaxial Cable Jumper Tools & Handles High Voltage Insulators

Manufacturing &

Process Equipment

Heat Transfer

Tubing & Plating

Aviation Instruments &

Assemblies

* Flame Retardant Meets UL 94 V-0 specications for self-extinguishing. Will not propagate ames.

Trusted by electric utility, aviation, military and maintenance for over 25 years

AREF-1001 Rev032518

Features

Typical Properties

Part List

Applications

Use on

900330220140112 903