Specifications

14

ENGLISH

3. Set pressure regulator (27) to

required working pressure. The cur-

rent working pressure is indicated

by the regulated pressure gauge

(28).

A

Caution!

Before connecting an air tool,

make sure the max. operating pres-

sure of the air tool used is not excee-

ded!

4. When using lubricated air adjust

amount of oil to be added with the

regulator knob (29).

5. Connect air tool.

You are now ready to work with the

air tool.

6. Switch the compressor OFF, if you

do not continue working immediately

afterwards. Unplug after switching

OFF.

A

Danger!

Prior to all servicing:

− Switch Off.

− Unplug.

− Wait until the compressor has

come to a complete stop.

− Ensure the compressor and all air

tools and accessories connected

to it are relieved from pressure.

After all servicing:

− Check to see that all safety

devices are operational.

− Make sure that no tools or other

parts remain on or in the

machine.

Repair and maintenance work other

than described in this section must

only be carried out by qualified speci-

alists.

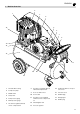

5.1 Periodic maintenance

Prior to each use

• Check oil level of lubricator (30), top

up with pneumatic oil if necessary.

• Check air hoses for damage,

replace if necessary.

• Check all screwed connections for

tightness, tighten if necessary.

• Check power supply cable for dam-

age, if necessary have replaced by

a qualified electrician.

Every 50 operating hours

• Check air filter element (31) of com-

pressor pump, clean if necessary.

• Check oil level (32) of compressor

pump, top up if necessary (33).

• Drain condensate from pressure

vessel (35).

• Clean air filter element (36) of filter/

regulator unit.

• Drain condensate from filter/regula-

tor unit (37).

• Check V-belt:

− Remove belt guard (38).

− Retension V-belt or replace, if

necessary.

− To adjust the V-belt tension,

loosen the four screws at the

motor base and shift the motor.

− Tighten the screws at the motor

base again.

− Replace the belt guard.

5. Care and Maintenance

29

30

31

32

34

33

35

36

37

O

O

F

F

AUTO

38