Air Cleaner User Manual

12

POWER SUPPLY

CHECKOUT PROCEDURE

1. Turn power switch to the “OFF” position and remove

the power pack from cabinet.

2. Place power pack on a well insulated workbench.

Connect meter negative (-) lead to the sheet metal

chassis and the high voltage probe to high voltage

contact on back cover of power pack. Connect AC

power to power pack using an extension cord and

turn power switch to the “ON” position. Keep hands

and tools away from high voltage contact.

3. If Operating Light comes ON and output voltage is

between 6100 and 6800 VDC, power supply is good.

4. If voltage is good but Operating Light does not come

on, replace Operating Light.

CELL TEST

1. Place collecting cell on a well insulated workbench

with the cell contact button pointing upward.

2. Select a power pack (with ozone reduction jumper

intact) that reads between 6100 and 6800 VDC at the

cell contact with no cell attached.

3. Place power pack on top of collecting cell ensuring

that there is proper contact between the cell contact

on the power pack contact.

4. Using a standard extension cord, apply 120 VAC to

power pack. Turn power switch to “ON” position.

5. Connect meter negative (-) lead to metal frame of

collecting cell. Use high voltage probe to measure

voltage at collecting cell ionizer or cell plates. Voltage

should be 6100 to 6800 VDC**.

NOTE: A new “out-of-box” cell may cause the voltage

to be lower than normal for a short period of time. To

obtain a more accurate measurement, “age” the cell

by applying high voltage to the cell for 15 to 30

minutes.

6 If voltage is below 6100 VDC, check cell for foreign

objects, bowed/bent/loose plates, broken ionizing

wires or cracked insulators. Wash cells if required. If

Operating Light remains OFF, replace collecting cell.

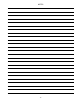

LINE

WHT/BRN BLK

W1

E3 E2

Ozone Reduction Jumper

Cut and separate

Ozone Reduction

Jumper

Figure 24

OZONE REDUCTION

All electronic air cleaners typically produce a small amount

of ozone that is within established limits. Some customers

may notice an odor especially at high altitudes or low air

flow rates.

This power supply has a “hairpin” shaped jumper wire

labeled W1 (see Fig 24) that can be cut and separated in

case of such complaints. This will cause the power supply

to limit the maximum operating power to a lower level.