Data Sheet

P/T Ratings for Valves (U.S. Units)

D101463X012

Product Bulletin

59.1:021

September 2013

12

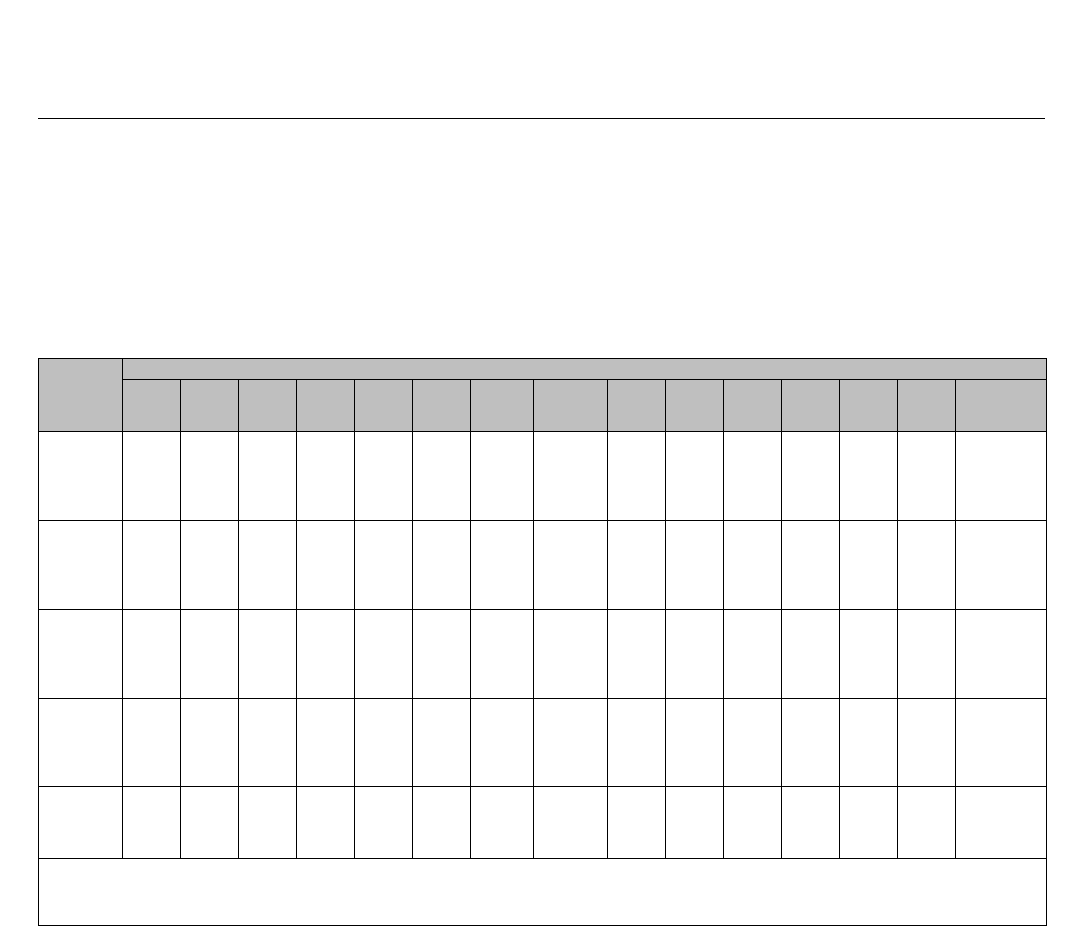

Special P ressure-Temperature Ratings for CL1500 and

CL2500 Threaded or Welding End Valves

Fisher valve materials that conform to ASME B16.34-2013 Special Class pressure-temperature ratings are listed in

tables 12 and 13. These ratings apply to all Fisher cast, forged, and fabricated steel valves. Nondestructive examination

applies (Fisher Process Level 6).

Table 12. For ASME Special CL1500 Valves

(1)

SERVICE

TEMP (_F)

WORKING PRESSURE (PSIG)

LCC LF2 WCC WC6 WC9

C12A

(2)

CF8

(2)

or 304

(2)

CF8M

(2)

or 316

(2)

CF3M 316L CG8M

317

(2)

CF8C

(2)

347

CK3MCuN

CD3MN

CD3MWCuN

-20 to 100

200

300

400

500

3750

3750

3750

3750

3750

3750

3750

3700

3665

3665

3750

3750

3750

3750

3750

3750

3750

3750

3750

3750

3750

3750

3695

3640

3620

3750

3750

3750

3750

3750

3750

3350

3000

2770

2600

3750

3455

3120

2865

2665

3750

3455

3120

2865

2665

3350

2855

2545

2345

2195

3750

3455

3120

2865

2665

3750

3455

3120

2865

2665

3750

3585

3295

3105

3000

3750

3695

3440

3215

3025

3750

3750

3725

3430

3240

600

650

700

750

800

3750

3750

---

---

---

3665

3575

3455

3170

2570

3750

3750

3565

3170

2570

3750

3750

3665

3645

3600

3605

3580

3535

3535

3535

3750

3750

3665

3645

3600

2465

2410

2355

2305

2265

2520

2465

2425

2385

2355

2520

2465

2425

2385

2355

2075

2035

2010

1970

1930

2520

2465

2425

2385

2355

2520

2465

2425

2385

2355

2880

2825

2770

2745

2720

2880

2825

2770

2745

2720

3105

3055

3025

3000

---

850

900

950

1000

1050

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

3385

2935

1995

1350

900

3385

3000

2360

1670

1095

3385

3000

2360

2105

2105

2210

2170

2130

2075

2035

2330

2315

2290

2105

2105

2330

---

---

---

---

1890

---

---

---

---

2330

2315

2290

2105

---

2330

2315

2290

2105

2105

2705

2705

2360

2105

2105

2705

2705

2360

2105

---

---

---

---

---

---

1100

1150

1200

1250

1300

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

600

---

---

---

---

685

---

---

---

---

1885

1395

900

---

---

1605

1285

1030

835

705

1905

1480

1155

920

730

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

1905

1480

1155

920

730

1950

1305

945

705

470

---

---

---

---

---

---

---

---

---

---

1350

1400

1450

1500

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

580

470

365

260

600

470

365

260

---

---

---

---

---

---

---

---

---

---

---

---

600

470

365

260

320

255

195

170

---

---

---

---

---

---

---

---

1. Table information is extracted from the Valve–Flanged, Threaded, and Welding End, ASME Standard B16.34-2013. These tables must be used in accordance with the ASME s tandard. The

ASME standard states in paragraph “2.1.3 Special Class Valves. Threaded or welding end valves that conform to all the requirements of para. 2.1.2 and in addition have successfully passed the

examinations required by Section 8, may be designated Special Class valves.” The standard also stipulates that, “Special Class ratings shall not be used for flanged end valves.” Information

copied with permission of the publisher; The American Society of Mechanical Engineers, 345 East 47th Street, New York, New York, 10017.

2. At temperatures over 1000_F, use material only when carbo n content is 0.04% or higher.