Data Sheet

P/T Ratings for Valves (U.S. Units)

D101463X012

Product Bulletin

59.1:021

September 2013

14

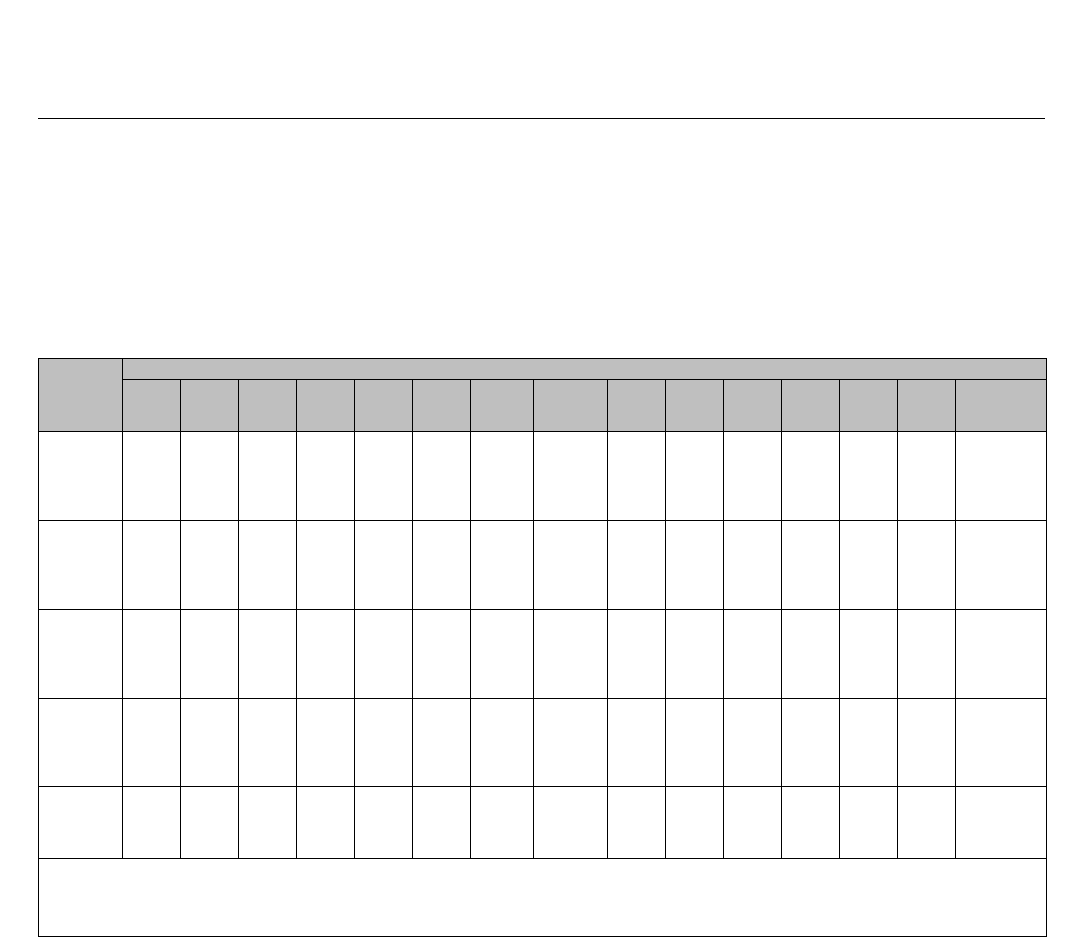

Standard and Special Pressure-Temperature Ratings for

CL4500 Valves

Fisher valve materials that conform to ASME B16.34-2013 Standard and Special Class pressure-temperature ratings are

listed in tables 14 and 15. These ratings apply to all Fisher cast, forged, and fabricated steel valves. For Special Class

pressure-temperature ratings, nondestructive examination applies (Fisher Process Level 6).

Table 14. For ASME Standard CL4500 Valves

(1)

SERVICE

TEMP (_F)

WORKING PRESSURE (PSIG)

LCC LF2 WCC WC6 WC9

C12A

(2)

CF8

(2,3)

or

304

(2,3)

CF8M

(2,3)

or 316

(2,3)

CF3M 316L CG8M

317

(2,3)

CF8C

(2,3)

347

CK3MCuN

CD3MN

CD3MWCuN

-20 to 100

200

300

400

500

11250

11250

10925

10555

9965

11110

10185

9815

9505

9040

11250

11250

10925

10555

9965

11250

11250

10830

10400

9965

11250

11250

10925

10585

9965

11250

11250

10925

10585

9965

10800

9000

8065

7450

6985

10800

9290

8390

7705

7165

10800

9290

8390

7705

7165

9000

7670

6840

6300

5905

10800

9290

8390

7705

7165

10800

9290

8390

7705

7165

10800

9935

9250

8640

8135

10800

9935

9250

8640

8135

11250

11160

10010

9215

8710

600

650

700

750

800

9070

8825

---

---

---

8515

8240

7960

7610

6170

9070

8825

8330

7610

6170

9070

8825

8515

7970

7610

9070

8825

8515

7970

7610

9070

8825

8515

7970

7610

6625

6480

6335

6190

6085

6770

6625

6515

6410

6335

6770

6625

6515

6410

6335

5580

5470

5400

5290

5185

6770

6625

6515

6410

6335

6770

6625

6515

6410

6335

7740

7595

7450

7380

7310

7740

7595

7450

7380

7310

8350

8210

8135

7970

---

850

900

950

1000

1050

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

7305

6740

4785

3240

2160

7305

6740

5795

4010

2625

7305

6740

5795

5450

5400

5940

5830

5725

5315

4885

6265

6230

5795

5450

5400

6265

---

---

---

---

5075

---

---

---

---

6265

6230

5795

5450

---

6265

6230

5795

5450

5400

7270

6740

5795

5450

5400

7270

6740

5795

5450

---

---

---

---

---

---

1100

1150

1200

1250

1300

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

1440

---

---

---

---

1645

---

---

---

---

4525

3345

2160

---

---

3855

3085

2470

2005

1695

4575

3550

2775

2210

1750

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

4575

3550

2775

2210

1750

4680

3135

2265

1695

1130

---

---

---

---

---

---

---

---

---

---

1350

1400

1450

1500

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

1390

1130

875

620

1440

1130

875

620

---

---

---

---

---

---

---

---

---

---

---

---

1440

1130

875

620

770

615

465

410

---

---

---

---

---

---

---

---

1. Table information is extracted from the Valve–Flanged, Threaded, and Welding End, ASME Standard B16.34-2013. These tables must be used in accordance with the ASME s tandard. The

user is advised that a valve used under the jurisdiction of the ASME Boiler and Pressure Vessel Code, ASME Code for Pressure Piping, or governmental regulations is subject to any limitation of

that code or regulation. This includes any maximum temperature limitation for a material or rule governing the use of a material at a low temperature.” Information copied with permission of

the publisher; The American Society of Mechanical Engineers, 345 East 47th Street, New York, New York, 10017.

2. Flanged end ratings terminate at 1000_F.

3. At temperatures over 1000_F, use material only when carbo n content is 0.04% or higher.