Intelligent Communications & Monitoring System User Manual

Table Of Contents

- 1.0 Introduction

- 2.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Status menu, large display, graphical view

- Figure 4 Liebert iCOM default screen symbols

- 2.1 Navigating Through the Liebert iCOM Menus

- 3.0 Operation

- 3.1 Single Unit Functions

- 3.2 Motorized Ball Valve in Digital Scroll Units

- 3.3 Temperature Control—Single Source Cooling (No Extra Cooling Coil)

- 3.3.1 Temperature Proportional Band

- 3.3.2 Compressor Control

- Compressor Proportional Bands

- Figure 12 One single-step compressor without unloaders

- Figure 13 Two single-step compressors without unloaders or one compressor with an unloader (two-step)

- Figure 14 Two compressors with unloaders (four-step)

- Figure 15 Digital scroll capacity modulation, 10-100% variable

- Figure 16 Single and dual digital scroll compressor activation points

- Compressor Proportional Bands

- 3.3.3 Chilled Water Control

- 3.4 Temperature Control—Second Cooling Source

- 3.5 Temperature Control—Reheat

- 3.6 Humidity Control

- 3.7 Control Types

- 3.8 Possible Event Notifications

- 3.9 Next Maintenance Calculation

- 4.0 Teamwork

- 5.0 Installing a Liebert iCOM Unit-to-Unit Network

- 5.1 Placement of Cooling Units

- 5.2 U2U Hardware: Cables and Network Switch

- 5.3 Wiring for Unit-to-Unit Communications—U2U

- 5.4 External Communications—Building Management Systems, Liebert SiteScan®

- 6.0 Mounting a Large Display on a Wall

- 7.0 User Menu Parameters

- 8.0 Service Menu Parameters

- Table 23 Setpoints parameters

- Unit Diary—Large Display Only

- Table 24 Unit diary parameters

- Table 25 Standby settings / lead-lag parameters

- Table 26 Maintenance / wellness settings parameters

- Table 27 Diagnostics / service mode parameters

- Table 28 Set alarms parameters

- Table 29 Sensor calibration / setup parameters

- Table 30 System / network setup parameters—large display only

- Table 31 Network setup parameters

- Table 32 Options setup parameters

- Table 33 Service contact info parameters

Operation

33

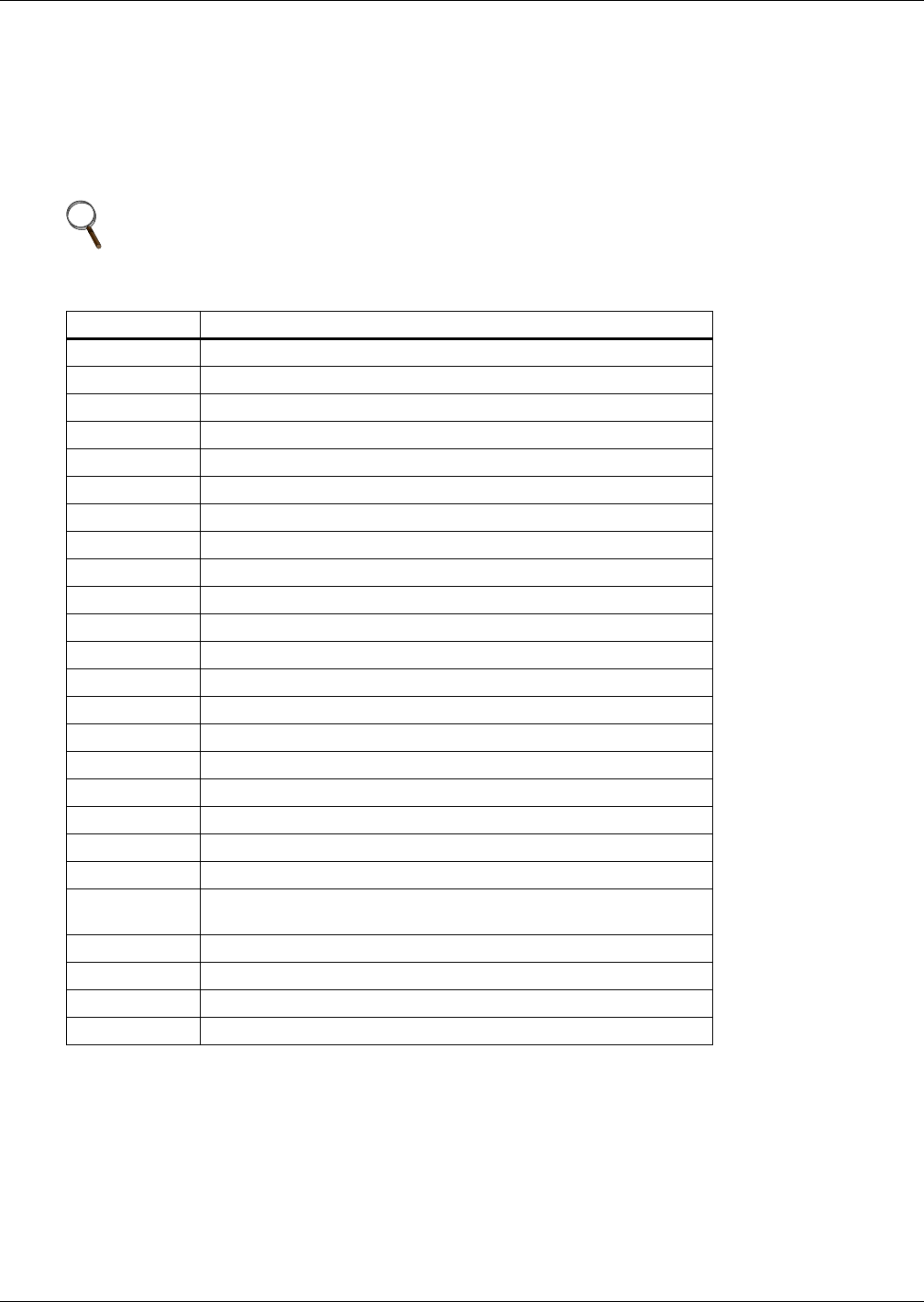

3.7.5 User Inputs / Customer Inputs

The user can connect and specify up to four inputs depending on unit configuration. The user

inputs/customer inputs are digital inputs that influence the operating mode of the unit depending on

the selection. The customer input configuration settings are in the Service menu under Set Alarms,

Screen 2 of 7. The choices for the customer inputs are shown in Table 7 along with their associated

reaction. A terminal strip is provided in the cooling unit to connect your contact closure to. You have

the ability to set the control to react on an open or closed contact.

NOTE

To enabled/disabled, delay activation and set event type (alarm, warn, message) see Event

Types on page 34.

Table 7 Customer inputs

Setting Reaction

Smoke Event Only

Water Alarm Event Only

C PMP Alarm Event Only

Flow Alarm Event Only

Stdby G Pmp Event Only

Stdby Unit Event Only

C-Input 1 Event Only

C-Input 2 Event Only

C-Input 3 Event Only

C-Input 4 Event Only

Rht Lockout Event + Electrical Heaters Disabled

Hum Lockout Event + Humidifier Disabled

Rht+Hum Lock Event + Electrical Heaters and Humidifier Disabled

Comp Lockout Event + Compressor(s) Disabled w/o Pump Down

Call Service Event Only

High Temp Event Only

Air Loss Event Only

FC Lockout Event + Free Cooling Disabled

Heater Alarm Event + Heaters Off (PeX Only)

Flow AL SD Event + Shut Down the Unit

Flow AL LC Event + Lockout Compressors, No Pump Down (enabled only if at

least one compressor is on; auto-reset depends on input status)

Comp Lock PD Event + Compressor(s) Disabled w/ Pump Down

Enable FC Forces Free Cooling to On

HTRJ VFD Activates the HEAT REJ VFD ALARM; no other function

HTRJ TVSS Activates the HEAT REJ TVSS ALARM; no other function