Intelligent Communications & Monitoring System User Manual

Table Of Contents

- 1.0 Introduction

- 2.0 Liebert iCOM Display Components and Functions

- Figure 2 Liebert iCOM display components

- Table 1 Keyboard icons and functions

- Figure 3 Status menu, large display, graphical view

- Figure 4 Liebert iCOM default screen symbols

- 2.1 Navigating Through the Liebert iCOM Menus

- 3.0 Operation

- 3.1 Single Unit Functions

- 3.2 Motorized Ball Valve in Digital Scroll Units

- 3.3 Temperature Control—Single Source Cooling (No Extra Cooling Coil)

- 3.3.1 Temperature Proportional Band

- 3.3.2 Compressor Control

- Compressor Proportional Bands

- Figure 12 One single-step compressor without unloaders

- Figure 13 Two single-step compressors without unloaders or one compressor with an unloader (two-step)

- Figure 14 Two compressors with unloaders (four-step)

- Figure 15 Digital scroll capacity modulation, 10-100% variable

- Figure 16 Single and dual digital scroll compressor activation points

- Compressor Proportional Bands

- 3.3.3 Chilled Water Control

- 3.4 Temperature Control—Second Cooling Source

- 3.5 Temperature Control—Reheat

- 3.6 Humidity Control

- 3.7 Control Types

- 3.8 Possible Event Notifications

- 3.9 Next Maintenance Calculation

- 4.0 Teamwork

- 5.0 Installing a Liebert iCOM Unit-to-Unit Network

- 5.1 Placement of Cooling Units

- 5.2 U2U Hardware: Cables and Network Switch

- 5.3 Wiring for Unit-to-Unit Communications—U2U

- 5.4 External Communications—Building Management Systems, Liebert SiteScan®

- 6.0 Mounting a Large Display on a Wall

- 7.0 User Menu Parameters

- 8.0 Service Menu Parameters

- Table 23 Setpoints parameters

- Unit Diary—Large Display Only

- Table 24 Unit diary parameters

- Table 25 Standby settings / lead-lag parameters

- Table 26 Maintenance / wellness settings parameters

- Table 27 Diagnostics / service mode parameters

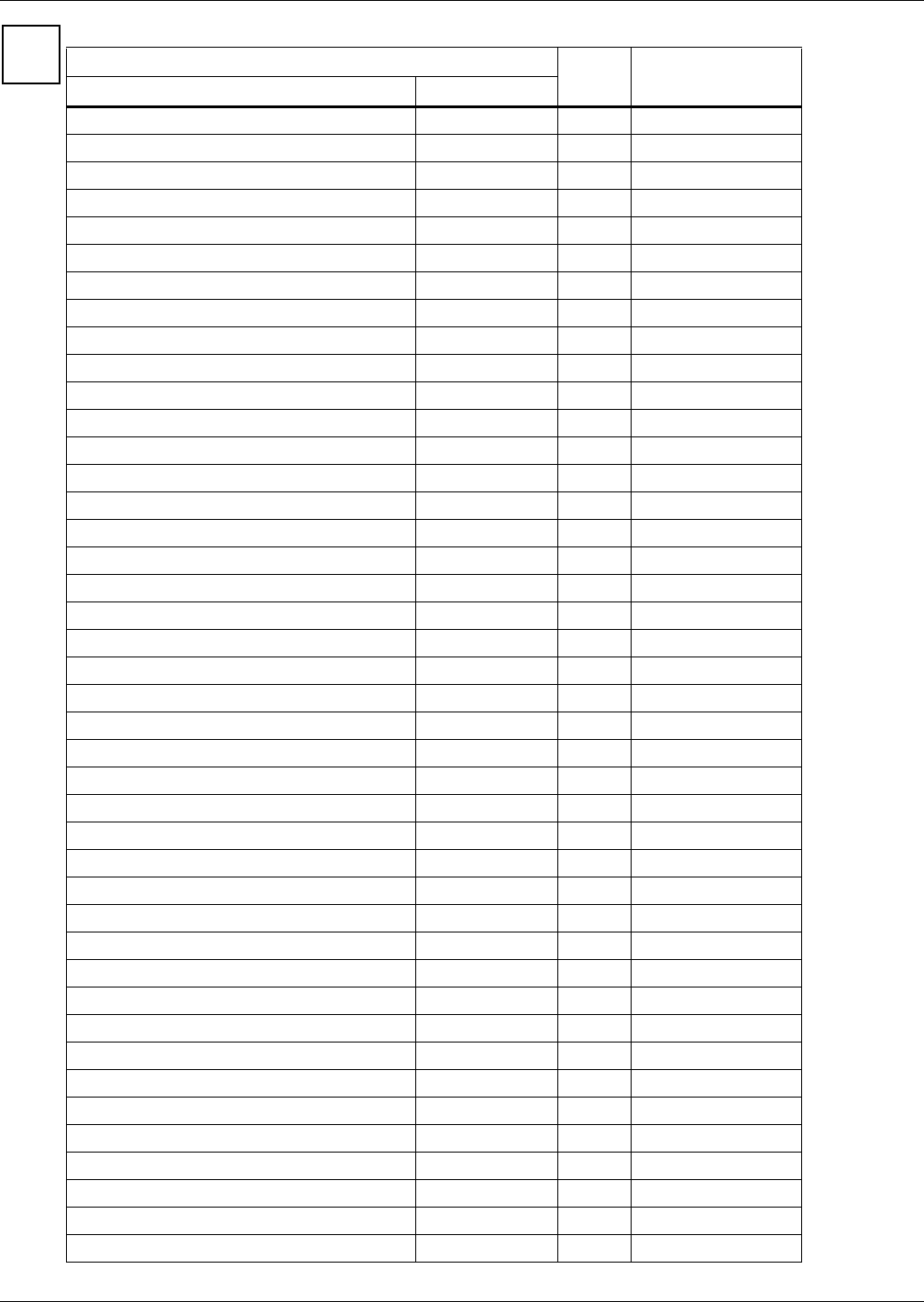

- Table 28 Set alarms parameters

- Table 29 Sensor calibration / setup parameters

- Table 30 System / network setup parameters—large display only

- Table 31 Network setup parameters

- Table 32 Options setup parameters

- Table 33 Service contact info parameters

Service Menu Parameters

66

ENABLE - DISAB - - -

COMP 1 OVERLOAD OL1 W Disabled, Enabled

COMP 2 OVERLOAD OL2 W Disabled, Enabled

COMP 1 HIGH PRESSURE HP1 W Disabled, Enabled

COMP 2 HIGH PRESSURE HP2 W Disabled, Enabled

COMP 1 LOW PRESSURE LP1 W Disabled, Enabled

COMP 2 LOW PRESSURE LP2 W Disabled, Enabled

COMP 1 PUMPDOWN FAIL PD1 W Disabled, Enabled

COMP 2 PUMPDOWN FAIL PD2 W Disabled, Enabled

DIG SCROLL1 HIGH TEMP HT1 W Disabled, Enabled

DIG SCROLL2 HIGH TEMP HT2 W Disabled, Enabled

EL HEAT HIGH TEMP EHO W Disabled, Enabled

TYPE -- -

COMP 1 OVERLOAD OL1 W MSG, WRN, ALM

COMP 2 OVERLOAD OL2 W MSG, WRN, ALM

COMP 1 HIGH PRESSURE HP1 W MSG, WRN, ALM

COMP 2 HIGH PRESSURE HP2 W MSG, WRN, ALM

COMP 1 LOW PRESSURE LP1 W MSG, WRN, ALM

COMP 2 LOW PRESSURE LP2 W MSG, WRN, ALM

COMP 1 PUMPDOWN FAIL PD1 W MSG, WRN, ALM

COMP 2 PUMPDOWN FAIL PD2 W MSG, WRN, ALM

DIG SCROLL1 HIGH TEMP HT1 W MSG, WRN, ALM

DIG SCROLL2 HIGH TEMP HT2 W MSG, WRN, ALM

EL HEAT HIGH TEMP EHO W MSG, WRN, ALM

Page 5 of 7

PASSWORD -W -

DELAY -- -

WORKING HRS EXCEEDED WHE W 0 - 9999 sec

SMOKE DETECTED SMO W 0 - 9999 sec

WATER UNDER FLOOR WUF W 0 - 9999 sec

COND PUMP-HIGH WATER CPH W 0 - 9999 sec

LOSS OF FLOW LOF W 0 - 9999 sec

STBY GLYCOL PUMP ON SGP W 0 - 9999 sec

STANDBY UNIT ON STB W 0 - 9999 sec

HUMIDIFIER PROBLEM HUP W 0 - 9999 sec

NO CONNECTION w/Unit1 NOC W internal

UNIT X DISCONNECTED - W internal

LOSS OF POWER LOP W internal

ENABLE - DISAB -- -

WORKING HRS EXCEEDED WHE W Disabled, Enabled

SMOKE DETECTED SMO W Disabled, Enabled

WATER UNDER FLOOR WUF W Disabled, Enabled

Table 28 Set alarms parameters (continued)

Function

Read/

Write

Range

Imperial (metric)

Large Display Small Display

SET

ALARMS