Instructions / Assembly

page 7

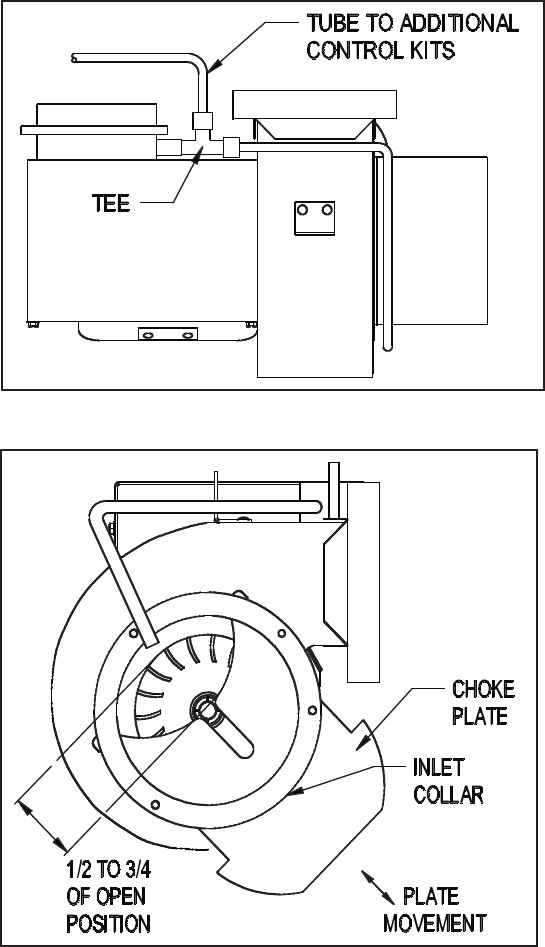

MULTIPLE APPLIANCE SYSTEMS

WhenusingonePVOpowerventertocommon

vent more than one appliance, a Control Kit is

required for each additional appliance.

Connect the negative pressure port of each air 1.

pressure fan proving switch on all Control Kits

being used to the provided tee mounted on

thePVO.(SeeFigure4)

Remove the cap from the branch of the tee 2.

and use the ferrule and compression nut

provided in the small envelope with the PVO

to attach the connecting tube.

Refer to the instruction sheet included with 3.

each Control Kit for specific instructions for

that kit, including wiring diagrams.

AIR FLOW ADJUSTMENT

NOTE: Beforeinstalling,refertotheGeneral

Installation Inspection to check for negative

pressure problems in the building.

To adjust the power venter air flow, open the 1.

choke plate

1

⁄2 to

3

⁄4ofthewayopen.(See

Figure5)Followtheappliancemanufacturer's

procedures for starting the heating appliance.

Adjustthethermostattocallfor"Heat."After2.

the system has operated for several minutes

to stabilize flue gas temperatures, use a draft

gauge, velocity meter, or match test procedure

to check for negative draft or up-draft at the

heating appliance outlet or air flow into the

draft hood.

Adjust the inlet choke damper on the power 3.

venter in or out to obtain the minimum air flow

required to maintain draft. Then increase air

owslightly(10%overminimumairowrate)

to ensure proper venting. For power burners, adjust draft to proper over-fired draft. If using a barometric

draft control, use the draft control to fine tune the

system draft.

If proper draft has been established, secure the choke plate by tightening the screws on the inlet collar.4.

Shut off thermostat and check for residual heat spilling from the draft hood or draft control. If this occurs, 5.

increase the post purge time on the timer.

Figure 4

Figure 5

NOTE: After proper venting has been established, it is recommended that a combustion test and a smoke test

be performed to ensure maximum burner efficiency. Oil burner air adjustments should be set at a zero to a

trace smoke at the highest or recommended CO

2

%settingsetbyheatingequipmentmanufacturer.