Product Manual

Table Of Contents

- Marine Generator Manual

- Current revision status

- 3. General Instructions and Regulations

- 3.1 Safety first!

- 3.2 Tools

- 3.3 Manufacturer declaration in accordance with the Machinery Directive 2006/42/EC

- 3.4 Customer registration and guarantee

- 3.5 Safety Instructions - Safety First!

- 3.5.1 Safe operation

- 3.5.2 Observe safety instructions!

- 3.5.3 Personal protective clothing (PPE)

- 3.5.4 Cleanliness ensures safety

- 3.5.5 Safe handling of fuels and lubricants

- 3.5.6 Exhaust fumes and fire protection

- 3.5.7 Safety precautions against burns and battery explosions

- 3.5.8 Protect your hands and body from rotating parts!

- 3.5.9 Anti-freeze and disposal of fluids

- 3.5.10 Implementation of safety inspections and maintenance

- 3.6 Warning and instruction signs

- 4. In case of Emergency First Aid / Im Notfall - Erste Hilfe

- 5. Basics

- 5.1 Intended use of the machine

- 5.2 Purpose of the manual and description of the definitions of the trained persons/operators/users

- 5.3 Components of the i-system

- 5.4 Panda transport box

- 5.5 Opening the GFK sound insulation capsule

- 5.6 Transport and loading/unloading

- 5.7 Special service instructions and measures for extended machine downtimes and decommissioning

- 6. Panda 5000i PMS generator

- 7. Installation Instructions

- 7.1 Personal requirements

- 7.2 Place of installation

- 7.3 Generator Connections

- 7.4 Installation of the cooling system - raw water

- 7.4.1 General information

- 7.4.2 Installation of the through hull fitting in Yachts - scheme

- 7.4.3 Quality of the raw water sucking in line

- 7.4.4 Generator installation above waterline

- 7.4.5 Generator installation below waterline

- 7.4.6 First filling and ventilation of the internal cooling water circuit

- 7.4.7 Temperature check for controlling the cooling water circuit

- 7.5 Installation of the water cooled exhaust system

- 7.6 .Installation of the waterlock

- 7.7 Exhaust / water separator

- 7.8 Installation exhaust water separator

- 7.9 Fuel system installation

- 7.10 Ventilating the fuel system

- 7.11 Generator DC system installation

- 7.12 Generator AC System Installation

- 7.13 Checking and filling of the oil circuit

- 7.14 Isolation test

- 7.15 Initial operation

- 8. Maintenance Instructions

- 8.1 Personal requirements

- 8.2 Personal requirements

- 8.3 Hazard notes for the maintenance and failure

- 8.4 Environmental protection

- 8.5 General maintenance instructions

- 8.6 Maintenance interval

- 8.7 Oil Change Intervals

- 8.8 Checking oil-level

- 8.9 Replacement of engine oil and engine oil filter

- 8.10 Verifying the starter battery and (if necessary) the battery bank

- 8.11 Checking the water separator in the fuel supply

- 8.12 De-aerating of the coolant circuit / freshwater

- 8.13 The raw water circuit

- 9. Generator Tables

- 10. Inverter Panda PMGi 5000

- Panda iControl2

- Current revision status

- Hardware

- 11. Safety instructions for the Panda iControl2

- 12. General operation

- 12.1 The Panda iControl2 panel

- 12.2 Starting preparation / Checks (daily)

- 12.3 Operation

- 12.4 Other operating functions

- 12.4.1 Set-up menu

- 12.4.2 Setting the brightness of the backlight ("backlight" and "dimtime")

- 12.4.3 The configuration menu ("config")

- 12.4.4 The network ID

- 12.4.5 Saving settings and exiting the set-up menu ("Save & Exit")

- 12.4.6 Activating/deactivating the autostart function ("Autostart")

- 12.4.7 Resetting the service interval ("Service")

- 12.4.8 Priming the fuel system ("Prime Fuel")

- 12.4.9 Selecting and saving a unit for the temperature value output

- 12.5 iControl2-Emergency-Stop

- 13. Installation

- 14. Maintenance

- 15. Annex

- 16. Warnings and error messages

- 16.1 Warnings

- 16.2 Faults

- 16.3 The error memory of the iControl 2 Panel

- 16.3.1 How to get to the error memory of the iControl2 Panel?

- 16.3.2 How are stored errors displayed?

- 16.3.3 How do I exit the error memory after having read the entries?

- 16.3.4 Can I delete the error memory?

- 16.3.5 Where are the errors stored?

- 16.3.6 In which language are the stored errors displayed?

- 16.3.7 Is it possible to upgrade an old iGenerator model by the error memory?

Warnings and error messages

13.4.17 Kapitel/Chapter 16: Warnings and error messages - Seite/Page 139

16.2.1 Error messages

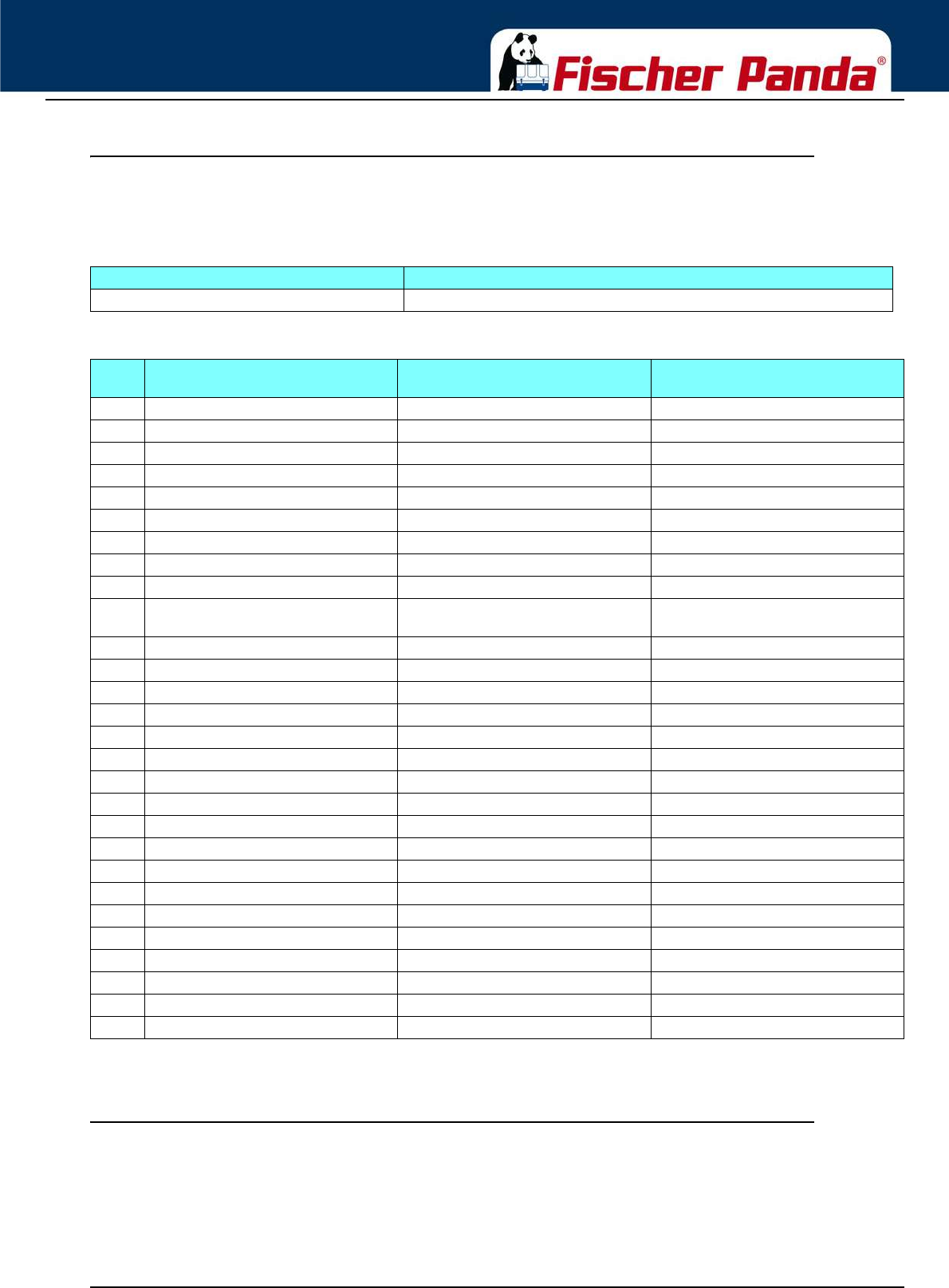

All error messages defined for the Panda iControl 2 and the corresponding display texts are compiled in the

subsequent table.

Fig. 16.2.1-1: Error messages

Fig. 16.2.1-2: Error codes

Error messages can be acknowledged with the Start/Stop button, The controller will then return to stand-by mode.

16.2.2 Warning and fault thresholds

The threshold values resulting in triggering warnings and faults depend on the generator type and are compiled in

table below.

Error message on the display Meaning of error message

„OUT“ is output instead of a temperature „Out of range“ - broken cable on corresponding temperature sensor

Error

code

Meaning Error Message English Error Message German

5 Starting failed STARTING FAILS STARTABBRUCH

9 Watchdog Error WATCHDOG WATCHDOG

12 Winding temperature fault FAULT: WINDING TEMP. WICKLUNG

13 Winding temperature out of range OUT: WINDING OUT: WICKLUNG

14 Exhaust temperature fault FAULT: EXHAUST TEMP. ABGAS

15 Exhaust temperature out of range OUT: EXHAUST OUT: ABGAS

16 Engine temperature fault FAULT: CYL.HEAD TEMP. MOTOR

17 Oil pressure fault FAULT: OILPRESS FEHLER: OELDRUCK

18 Battery voltage low BATTERY LOW BATTERIE ENTLADEN

19 unexpected stop/Problem with fuel supply PROBLEM WITH / FUEL SUPPLY! PROBLEM MIT DER /

KRAFTSTOFFVERS.!

22 Emergency stop EMERGENCY STOP! NOT-HALT!

23 Engine temperature out of range OUT: CYL.HEAD OUT: MOTOR

30 Inverter overtemp Inverter overtemp Inverter Uebertemp.

31 inverter overload Inverter overload Inverter Ueberlast

32 inverter communication lost Inverter com. lost Inverter Kom. defekt

33 inverter synchronisation lost INV. SYNC. FAILED INV. SYNC. FEHLER

34 Engine fault (EDC) ENGINE FAULT MOTOR FEHLER

35 CAN communication lost CAN. COMM.LOST CAN KOMM. FEHLER

36 inverter overload slave 1 L1 OVERLOAD L1 UEBERLAST

37 inverter overload slave 2 L2 OVERLOAD L2 UEBERLAST

38 inverter overload slave 3 L3 OVERLOAD L3 UEBERLAST

39 inverter overload slave DC DC OVERLOAD DC UEBERLAST

40 Overvoltage FAULT: OVERVOLTAGE Fehler: Ueberspg.

41 Undervoltage FAULT: LOWVOLTAGE Fehler: Unterspg.

42 DC-Overvoltage DC OVERVOLTAGE DC UEBERSPG.

66 RedundantTempSwitchOff NOTSTOP! NOTSTOPP!

100 Communication Error NO CONNECTION / BUS ERROR! KEINE VERBINDUNG / BUS FEHLER!

207 Init failed (no generator type is selected) INIT FAILED! INIT FAILED!