Application Note

Application Note

Using a Fluke ScopeMeter

125 to Troubleshoot

FOUNDATION

™

Fieldbus Installations

From the Fluke Digital Library @ www.fluke.com/library

1) Disruptive environmental

conditions, which include

mechanical vibrations, extreme

temperature changes, high

humidity levels and poor air

quality caused by chemicals,

dust and other agents. These

conditions can create loose

or intermittent connections,

corrosion in conductors and

junction boxes and/or changes

in impedance.

2) Electrical disturbances come

from a variety of sources.

Breakers turn high-energy

circuits on and off generating

transients. Belt conveyors and

mechanical drives discharge

high-voltage static electricity

into electronic systems. Load

changes on branch circuits

create fluctuations in supply

voltages. And there are still

other possible sources of elec-

trical disturbances.

Both types of disturbances

can temporarily or perma-

nently adversely affect system

components—terminators, input

components and cabling. The

result often is a disruption of the

millivolt signals upon which pro-

duction processes rely. Therefore,

it makes great sense to avoid

potential process communications

problems and pinpoint exist-

ing problems by monitoring and

Industrial fieldbus networks operate under very

different conditions than do office and other commercial

communications networks. In the industrial world,

external influences can play havoc with sensitive

electronic devices such as PLCs, network controllers

and other instruments supporting process control. These

external, industrial influences fall into two categories:

troubleshooting industrial digital

communications systems using an

oscilloscope.

The following discussion

focuses on the monitoring of

a specific type of system, FOUN-

DATION Fieldbus 31.25 kb/s

(H1) networks, using a new

instrument designed and

programmed for such monitor-

ing: the Fluke 125 Industrial

ScopeMeter

®

test tool.

(Note: The Fluke 125 is not limited to moni-

toring just Fieldbus H1 networks.)

Troubleshooting

procedures

When troubleshooting a Fieldbus

system, first attempt to document

recent changes to the system:

Have any devices or any parts

of the network recently been

disconnected? Was anything

added or modified just before the

trouble began?

Determine what’s working

and what’s not. Make notes

about what is observed versus

what was expected. Investigate

whether certain disturbances can

be traced back to specific events:

a motor starting, a valve opening,

a light being turned on, etc.

Next, make measurements to

“look into” the network in order

to see and understand what’s

going on. Carefully document

each measurement: What was

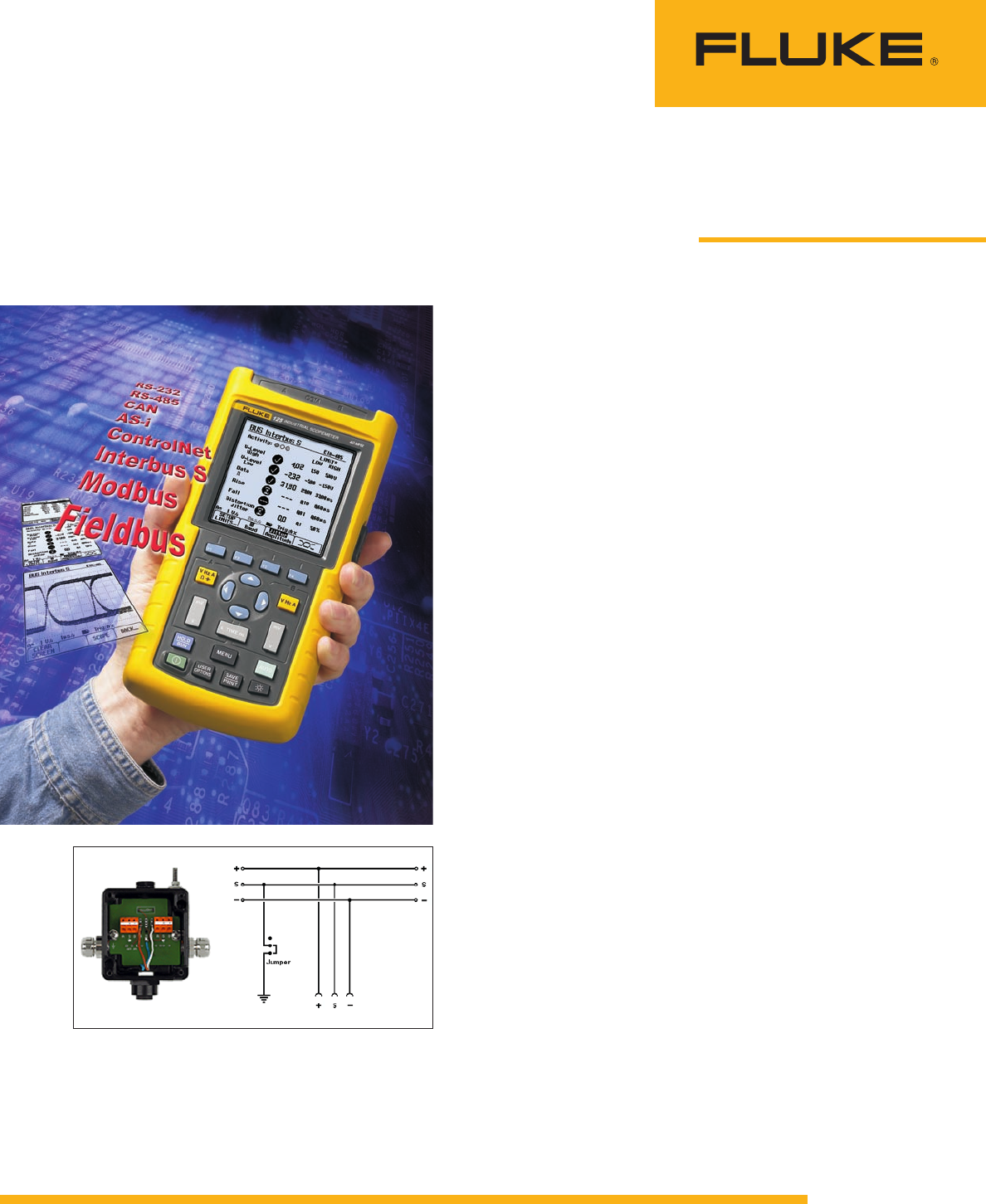

Figure 1: A typical FOUNDATION Fieldbus junction box

with wiring diagram.