Spec Sheet

Table Of Contents

10

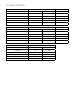

Typical Wall Sleeve Installation (PDXWSA)

INSTALLATION

Note the use of a lintel under the rst course

of bricks above the wall sleeve. Do not use the

wall sleeve as a lintel. The mounting screw

holes shown are to be made by the installer.

Note: All 230/208V units are manufactured with

a 60" power cord and all 265V units with an 18"

power cord. The receptacle locations above

must be followed to ensure proper connections.

FRP008

20

"

MAX.

16-¼

"

42-¼

"

MIN.

LINTEL TO SUPPORT

MASONRY WALLS

ELECTRICAL

RECEPTACLE

ELECTRICAL

RECEPTACLE

WALL OPENING

WALL SLEEVE

INSULATION

INSULATION

SMOOTH SIDE OF SCREW

CLIP FACING INTO ROOM

NOTE: All 230/208V units are manufactured with a 72” power cord and all 265V units with a 20” power cord.

60

"

MAX.

13-¾

"

FRP010

NO

TE: Construct wall opening to comply with all applicable building codes.

MAIN STUDS

JACK STUDS

LINTEL

MOUNTING

SCREW HOLES

NO HOLES IN BOTTOM OF WALL

SLEEVE UNLESS DRAIN KIT IS USED

MAIN STUDS

JACK STUDS

PDXWSA Wall Sleeve Dimensions:

16" H x 42" W x 13

3

/4" D

Front Cover Dimensions:

16" H x 42" W x 7

3

/4" D

Cut-Out Dimensions:

16

1

/4" x 42

1

/4"

IMPORTANT NOTE:

The silicone bead MUST extend up

the side of the two anges to prevent

condensate from leaking.

Seal condensate drip pan to wall

sleeve with sealant on all (4)

bottom corners.

Deep Wall Sleeve Installation