- General Electric Computer Accessories User Manual

Table Of Contents

- Safety Symbol Legend

- Chapter 1 Overview

- Chapter 2 Faults and Troubleshooting

- Chapter 3 Paramters/Functions

- Introduction

- Diagnostic and Utility Functions

- Drive Configuration Functions

- General Setup Functions

- I/O Functions

- LAN Functions

- Motor Control Functions

- Protective Functions

- Custom User Faults

- DC Link Protection

- Ground Fault Protection (Fast)

- Hardware Fault Strings

- Heatsink Thermal Protection

- Line-Line Voltage Protection

- Motor Overtemperature Detection

- Phase Current Protection

- Timed Overcurrent Detection

- Transformer Overtemperature Detection

- Motor Ground Protection

- Phase Imbalance Monitor

- Line Monitor

- Phase Lock Loop

- Sequencer Functions

- Speed Reference Functions

- Speed/Torque Control Functions

- System Data Parameters

- Chapter 4 Wizards

- Introduction

- Introduction 4-1

- DAC Setup

- Drive Commissioning

- Drive Commissioning: Overview

- Drive Commissioning: Intelligent Part Number

- Drive Commissioning: Drive Units

- Drive Commissioning: AC Source Selection

- Drive Commissioning: Motor Nameplate Data

- Drive Commissioning: Motor Crossover Voltage

- Drive Commissioning: Motor Protection Class

- Drive Commissioning: Motor Poles

- Drive Commissioning: Motor Data Sheet

- Drive Commissioning: Motor Data Sheet - Equivalent Circuit Data

- Drive Commissioning: Motor Data Sheet - Flux Curve

- Drive Commissioning: Motor and Process Speed Referencing

- Drive Commissioning: Tachometer Support

- Drive Commissioning: Tachometer Pulses Per Revolution

- Drive Commissioning: Tachometer Loss Protection

- Drive Commissioning: Stopping Configuration

- Drive Commissioning: Flying Restart

- Drive Commissioning: X-Stop Configuration

- Drive Commissioning: X-Stop Ramp Time

- Drive Commissioning: Run Ready Permissive String

- Drive Commissioning: Starting and Stopping the Drive

- Drive Commissioning: Manual Reference

- Drive Commissioning: Maximum Speed References

- Drive Commissioning: Jog Speed Setpoints

- Drive Commissioning: Reference Ramp Bypass

- Drive Commissioning: Reference Ramp Mode

- Drive Commissioning: Reference Ramp Speed Independent Rates

- Drive Commissioning: Reference Ramp Speed Independent Rate Set Selection

- Drive Commissioning: Reference Ramp Programmed Acceleration Rates

- Drive Commissioning: Reference Ramp Programmed Acceleration Speeds

- Drive Commissioning: Reference Ramp Programmed Deceleration Rates

- Drive Commissioning: Reference Ramp Programmed Deceleration Speeds

- Drive Commissioning: DDI Increment and Decrement Rates (Local Mode)

- Drive Commissioning: Speed/Torque Regulator Configuration

- Drive Commissioning: Speed/Torque Regulator Modes

- Drive Commissioning: Torque Regulator Reference and Output

- Drive Commissioning: Torque with Speed Override Reference and Output

- Drive Commissioning: Torque with Speed Override Speed Error

- Drive Commissioning: Torque with Speed Override Stopping Behavior

- Drive Commissioning: Torque and Current Limits

- Drive Commissioning: Torque and Current Limits Uniform

- Drive Commissioning: Failed Calculation

- Drive Commissioning: Torque and Current Limit Selection

- Drive Commissioning: Normal Torque and Current Limits

- Drive Commissioning: Alternate Torque and Current Limits

- Drive Commissioning: Motoring Torque Limits

- Drive Commissioning: Generating Torque Limits

- Drive Commissioning: Current Limits

- Drive Commissioning: Power Dip Ride-Through

- Drive Commissioning: Parameter Calculation

- Drive Commissioning: Simulator Mode

- Drive Commissioning: Hardware Fault Strings in Simulator Mode

- Drive Commissioning: Simulator Mechanical Configuration

- Drive Commissioning: Exit Reminder

- Drive Commissioning: Conclusion

- Line Transfer Tuneup

- Motor Control Tuneup

- Panel Meter Setup

- Per Unit Setup

- Line Protection Setup

- Pulse Test

- Remaining Parameter Setup

- Simulator Setup

- Speed Regulator Tuneup

- Speed Regulator Tuneup: Model

- Speed Regulator Tuneup: System Inertia

- Speed Regulator Tuneup: Inertia Measurement Command

- Speed Regulator Tuneup: Speed Regulator Mode

- Speed Regulator Tuneup: Manual Regulator Tuneup

- Speed Regulator Tuneup: 1st Order Response

- Speed Regulator Tuneup: 2nd Order Response

- Speed Regulator Tuneup: 2nd Order Response with Stiffness Filter

- Speed Regulator Tuneup: Calculate Speed Regulator Gains Command

- Notes

- Chapter 5 Signal Mapping

- Appendix A Function Block Diagrams

- Index

- Reader Comments

Digital Inputs/Outputs & Mapping

Overview

Overview

NAVIGATION

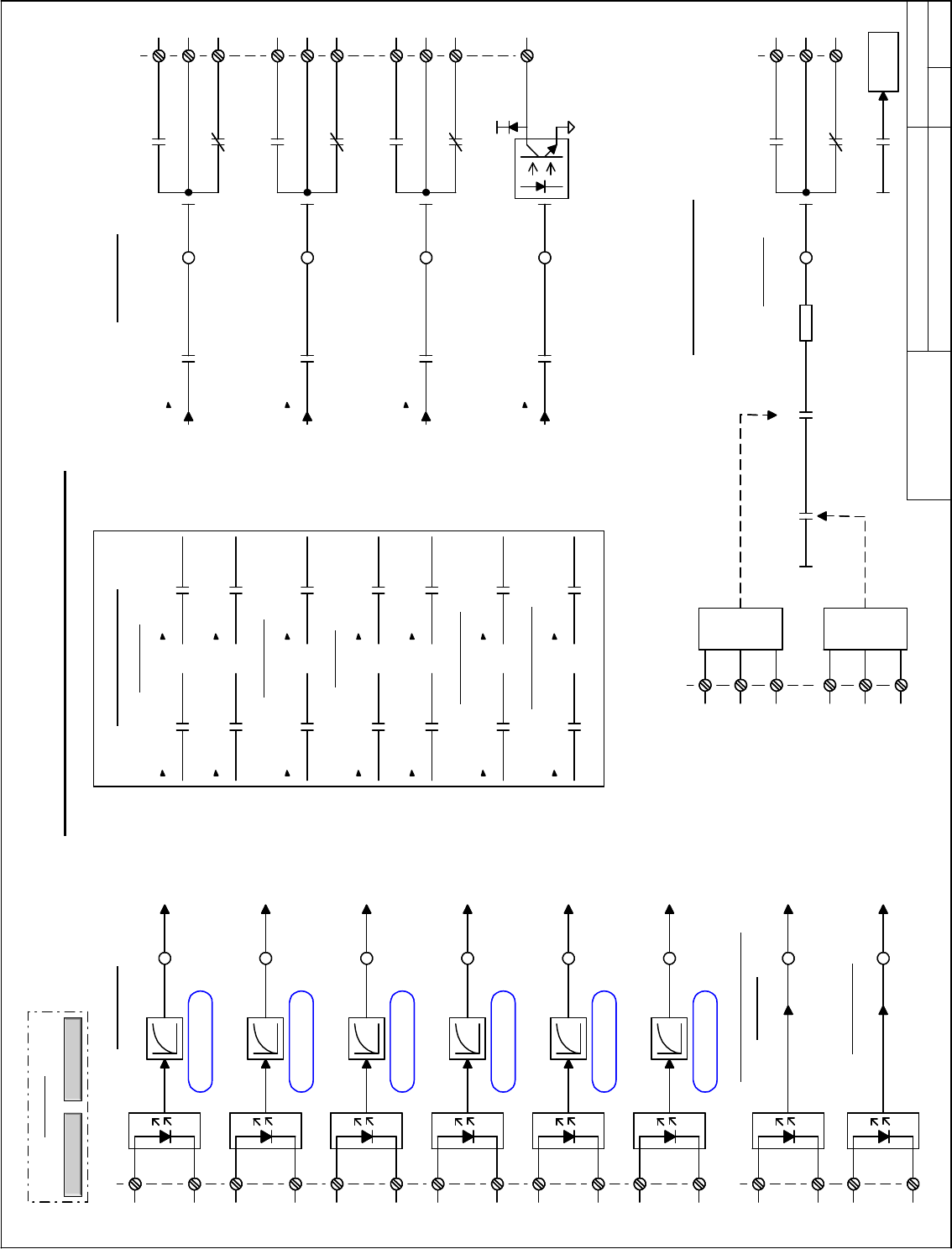

HWIO_Dig.vsd

Innovation Control

Device name: Date:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

GE Motors and

Industrial Systems

Salem, Va. USA

PRODUCT:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

A B C D E F G H I J K L M N O P Q R S T U

A B C D E F G H I J K L

March 10, 1999

saved date:

Page name:

Sequencing Selectors

Digital Inputs

HWIO_Ana

Analog I/O

Tachometer Marker

MA Feedback

*

- 2-5ms HW Filtering

*

1-

16

1+

14

*

2-

20

2+

18

*

3-

24

3+

22

*

4-

28

4+

26

*

5-

32

5+

30

*

6-

36

6+

34

*

MA-

9

MA+

7

/MKR

53

MKR

51

Dedicated Digital Inputs

Relay Outputs

+24Vdc

R1NO

15

R1NC

19

R2NO

21

R2NC

25

R3NO

27

R3NC

31

DRVR

11

MANO

1

MANC

5

S24V

4

L24V

10

S115V

2

L115V

8

SCOM

6

LCOM

12

MACOM

3

R1COM

17

R2COM

23

R3COM

29

ATBA

ATBA

MA Pilot Relay

Dedicated Relay Outputs

ATBA

Stop Commands

Faults & Reset

Permissives

Run / Jog Requests

Regulator Commands

ATBA

ATBA

Logic

P5

S

Y

S

T

E

M

F

A

U

L

T

L

O

C

A

L

F

A

U

L

T

24COM

I

To Bridge

Enable

NotNot

Jun 06, 2000ISD1

Fault reset select

Unused boolean

Run permissive sel

Unused boolean

Run request select

Unused boolean

Jog request select

Unused boolean

Full flux req sel

Unused boolean

MA close req sel

Unused boolean

Reverse select

Unused boolean

X stop request sel

Unused boolean

Digital input 1

VCO 3 unfiltered

Digital in 1 filter

0

Digital input 2

Digital in 2 filter

0

Digital input 3

Digital in 3 filter

0

Digital input 4

Digital in 4 filter

0

Digital input 5

Digital in 5 filter

0

Digital input 6

Digital in 6 filter

0

Start permissive sel

Unused boolean

MA contactor closed

Relay 1 state

Relay 2 state

Relay 3 state

Solid state relay

Relay 1 state

Relay 1 state

Relay 2 state

Relay 2 state

Relay 3 state

Relay 3 state

MA close command

MA close command

MA close command

Relay 1 select

Unused boolean

Relay 2 select

Unused boolean

Relay 3 select

Unused boolean

SS relay driver sel

Unused boolean

Stop PB select

Unused boolean

User NC fault sel

Unused boolean

User NO fault sel

Unused boolean

Motor OT fault sel

Unused boolean

Torque mode sel

Force True

MA close command

System fault stringLocal fault string

Digital Inputs/Outputs & Mapping

Overview

Overview

NAVIGATION

HWIO_Dig.vsd

Innovation Control

Device name: Date:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

GE Motors and

Industrial Systems

Salem, Va. USA

PRODUCT:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

A B C D E F G H I J K L M N O P Q R S T U

A B C D E F G H I J K L

March 10, 1999

saved date:

Page name:

Sequencing Selectors

Digital Inputs

HWIO_Ana

Analog I/O

Tachometer Marker

MA Feedback

*

- 2-5ms HW Filtering

*

1-

16

1+

14

*

2-

20

2+

18

*

3-

24

3+

22

*

4-

28

4+

26

*

5-

32

5+

30

*

6-

36

6+

34

*

MA-

9

MA+

7

/MKR

53

MKR

51

Dedicated Digital Inputs

Relay Outputs

+24Vdc

R1NO

15

R1NC

19

R2NO

21

R2NC

25

R3NO

27

R3NC

31

DRVR

11

MANO

1

MANC

5

S24V

4

L24V

10

S115V

2

L115V

8

SCOM

6

LCOM

12

MACOM

3

R1COM

17

R2COM

23

R3COM

29

ATBA

ATBA

MA Pilot Relay

Dedicated Relay Outputs

ATBA

Stop Commands

Faults & Reset

Permissives

Run / Jog Requests

Regulator Commands

ATBA

ATBA

Logic

P5

S

Y

S

T

E

M

F

A

U

L

T

L

O

C

A

L

F

A

U

L

T

24COM

I

To Bridge

Enable

NotNot

Jun 06, 2000ISD1

Fault reset select

Unused boolean

Run permissive sel

Unused boolean

Run request select

Unused boolean

Jog request select

Unused boolean

Full flux req sel

Unused boolean

MA close req sel

Unused boolean

Reverse select

Unused boolean

X stop request sel

Unused boolean

Digital input 1

VCO 3 unfiltered

Digital in 1 filter

0

Digital input 2

Digital in 2 filter

0

Digital input 3

Digital in 3 filter

0

Digital input 4

Digital in 4 filter

0

Digital input 5

Digital in 5 filter

0

Digital input 6

Digital in 6 filter

0

Start permissive sel

Unused boolean

MA contactor closed

Relay 1 state

Relay 2 state

Relay 3 state

Solid state relay

Relay 1 state

Relay 1 state

Relay 2 state

Relay 2 state

Relay 3 state

Relay 3 state

MA close command

MA close command

MA close command

Relay 1 select

Unused boolean

Relay 2 select

Unused boolean

Relay 3 select

Unused boolean

SS relay driver sel

Unused boolean

Stop PB select

Unused boolean

User NC fault sel

Unused boolean

User NO fault sel

Unused boolean

Motor OT fault sel

Unused boolean

Torque mode sel

Force True

MA close command

System fault stringLocal fault string