- General Electric Computer Accessories User Manual

Table Of Contents

- Safety Symbol Legend

- Chapter 1 Overview

- Chapter 2 Faults and Troubleshooting

- Chapter 3 Paramters/Functions

- Introduction

- Diagnostic and Utility Functions

- Drive Configuration Functions

- General Setup Functions

- I/O Functions

- LAN Functions

- Motor Control Functions

- Protective Functions

- Custom User Faults

- DC Link Protection

- Ground Fault Protection (Fast)

- Hardware Fault Strings

- Heatsink Thermal Protection

- Line-Line Voltage Protection

- Motor Overtemperature Detection

- Phase Current Protection

- Timed Overcurrent Detection

- Transformer Overtemperature Detection

- Motor Ground Protection

- Phase Imbalance Monitor

- Line Monitor

- Phase Lock Loop

- Sequencer Functions

- Speed Reference Functions

- Speed/Torque Control Functions

- System Data Parameters

- Chapter 4 Wizards

- Introduction

- Introduction 4-1

- DAC Setup

- Drive Commissioning

- Drive Commissioning: Overview

- Drive Commissioning: Intelligent Part Number

- Drive Commissioning: Drive Units

- Drive Commissioning: AC Source Selection

- Drive Commissioning: Motor Nameplate Data

- Drive Commissioning: Motor Crossover Voltage

- Drive Commissioning: Motor Protection Class

- Drive Commissioning: Motor Poles

- Drive Commissioning: Motor Data Sheet

- Drive Commissioning: Motor Data Sheet - Equivalent Circuit Data

- Drive Commissioning: Motor Data Sheet - Flux Curve

- Drive Commissioning: Motor and Process Speed Referencing

- Drive Commissioning: Tachometer Support

- Drive Commissioning: Tachometer Pulses Per Revolution

- Drive Commissioning: Tachometer Loss Protection

- Drive Commissioning: Stopping Configuration

- Drive Commissioning: Flying Restart

- Drive Commissioning: X-Stop Configuration

- Drive Commissioning: X-Stop Ramp Time

- Drive Commissioning: Run Ready Permissive String

- Drive Commissioning: Starting and Stopping the Drive

- Drive Commissioning: Manual Reference

- Drive Commissioning: Maximum Speed References

- Drive Commissioning: Jog Speed Setpoints

- Drive Commissioning: Reference Ramp Bypass

- Drive Commissioning: Reference Ramp Mode

- Drive Commissioning: Reference Ramp Speed Independent Rates

- Drive Commissioning: Reference Ramp Speed Independent Rate Set Selection

- Drive Commissioning: Reference Ramp Programmed Acceleration Rates

- Drive Commissioning: Reference Ramp Programmed Acceleration Speeds

- Drive Commissioning: Reference Ramp Programmed Deceleration Rates

- Drive Commissioning: Reference Ramp Programmed Deceleration Speeds

- Drive Commissioning: DDI Increment and Decrement Rates (Local Mode)

- Drive Commissioning: Speed/Torque Regulator Configuration

- Drive Commissioning: Speed/Torque Regulator Modes

- Drive Commissioning: Torque Regulator Reference and Output

- Drive Commissioning: Torque with Speed Override Reference and Output

- Drive Commissioning: Torque with Speed Override Speed Error

- Drive Commissioning: Torque with Speed Override Stopping Behavior

- Drive Commissioning: Torque and Current Limits

- Drive Commissioning: Torque and Current Limits Uniform

- Drive Commissioning: Failed Calculation

- Drive Commissioning: Torque and Current Limit Selection

- Drive Commissioning: Normal Torque and Current Limits

- Drive Commissioning: Alternate Torque and Current Limits

- Drive Commissioning: Motoring Torque Limits

- Drive Commissioning: Generating Torque Limits

- Drive Commissioning: Current Limits

- Drive Commissioning: Power Dip Ride-Through

- Drive Commissioning: Parameter Calculation

- Drive Commissioning: Simulator Mode

- Drive Commissioning: Hardware Fault Strings in Simulator Mode

- Drive Commissioning: Simulator Mechanical Configuration

- Drive Commissioning: Exit Reminder

- Drive Commissioning: Conclusion

- Line Transfer Tuneup

- Motor Control Tuneup

- Panel Meter Setup

- Per Unit Setup

- Line Protection Setup

- Pulse Test

- Remaining Parameter Setup

- Simulator Setup

- Speed Regulator Tuneup

- Speed Regulator Tuneup: Model

- Speed Regulator Tuneup: System Inertia

- Speed Regulator Tuneup: Inertia Measurement Command

- Speed Regulator Tuneup: Speed Regulator Mode

- Speed Regulator Tuneup: Manual Regulator Tuneup

- Speed Regulator Tuneup: 1st Order Response

- Speed Regulator Tuneup: 2nd Order Response

- Speed Regulator Tuneup: 2nd Order Response with Stiffness Filter

- Speed Regulator Tuneup: Calculate Speed Regulator Gains Command

- Notes

- Chapter 5 Signal Mapping

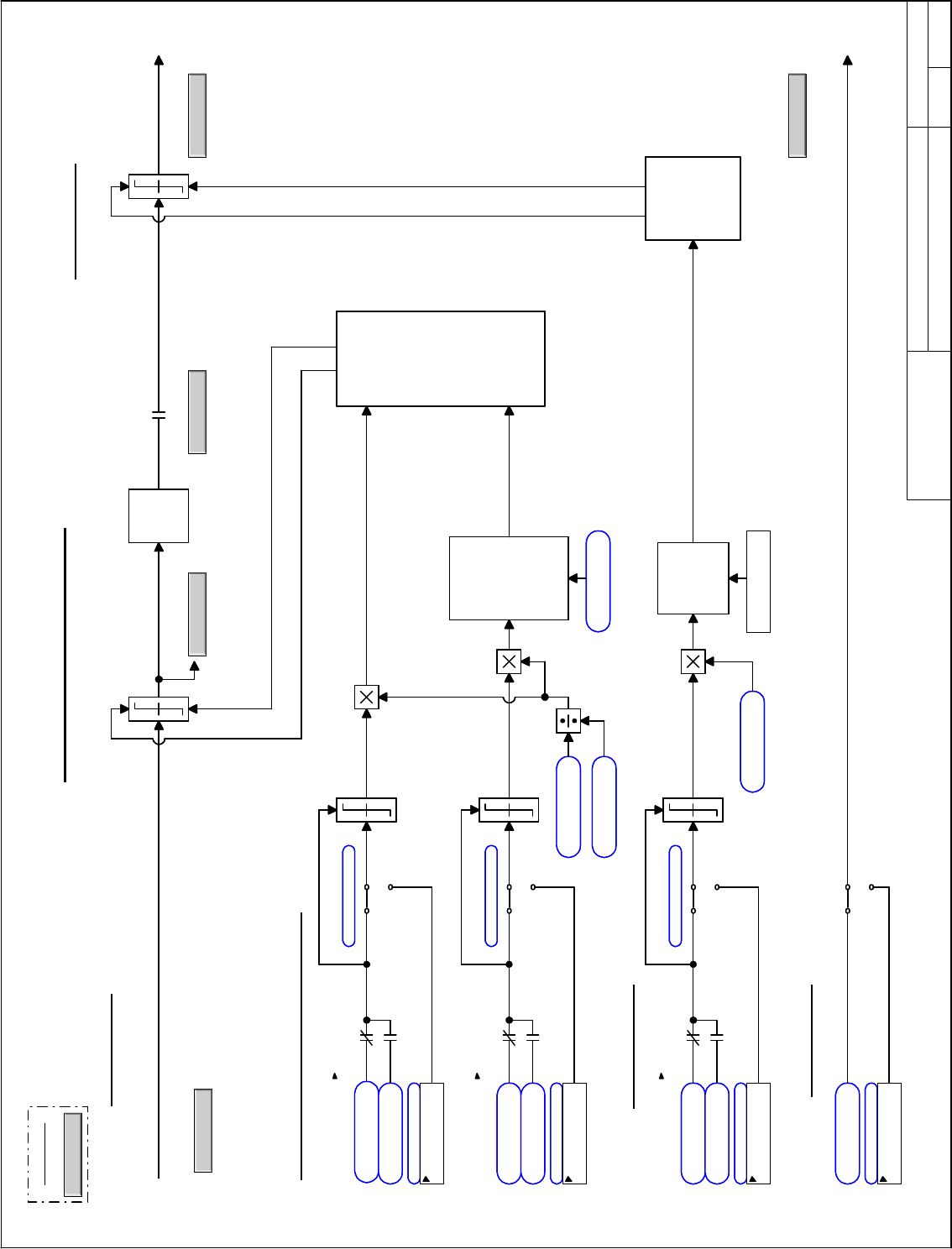

- Appendix A Function Block Diagrams

- Index

- Reader Comments

January 29, 1999

Core.vsd

Innovation Control

Device name: Date:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

GE Motors and

Industrial Systems

Salem, Va. USA

PRODUCT:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

A B C D E F G H I J K L M N O P Q R S T U

A B C D E F G H I J K L

saved date:

Page name:

Motor Control Interface

From Speed Regulator

Ovr_SpTq

Back to Overview

NAVIGATION

SReg

Torque Command

Motoring & Generating Torque Limit Select

Torque

Compen-

sation

Current Command

Current Limit Select

Motoring &

Generating Limit

Steering Control

Ovr_MCtrl

To Motor Control

Current

Magnitude

Limit

Pullout Limit

Adjustment

and

Power-Dip

Clamp

Control

DC Bus

Regen Control

can reduce

Generating

Limit

Not Used

Not Used

Not Used

From Sequencer

GenSeq_5

To Droop Feedback

Droop

0

0

0

Flux Adjust Select

Not Used

Ovr_MCtrl

To Motor Control

Jun 06, 2000ISD1

Current limit

Torque ref pre limit

Torque current limit

Torque lim 2 sel

Force False

Torque lim 2 sel

Force False

Torque lim 2 sel

Force False

Motoring torque lim

Regen torque limit

Torque ref post lim

Motoring torque lim1

1 pu

Motoring torque lim2

1 pu

Regen torque lim 1

1 pu

Regen torque lim 2

1 pu

Trq cur ref pre lim

Current limit 1

1 pu

Current limit 2

1 pu

Torque current ref

Motor rated current

<No Value> Amps

Adj mtr trq lim sel

Unused float

Adj gen trq lim sel

Unused float

100% Motor torque

Adj cur lim ref sel

Unused float

Motor rated power

<No Value> KW

Motor rated rpm

<No Value> RPM

Flux current, avg

Adj mtr trq lim sel

Adj gen trq lim sel

Adj cur lim ref sel

Dc source

Rectifier without DB

Torque enable req

Ix command pos limit

Torque cmd neg limit

Ix command neg limit

Torque cmd pos limit

Flux ref ratio setpt

1

Flux ref ratio sel

Unused float

Flux ref ratio sel

Flux ref ratio

January 29, 1999

Core.vsd

Innovation Control

Device name: Date:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

GE Motors and

Industrial Systems

Salem, Va. USA

PRODUCT:

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

A B C D E F G H I J K L M N O P Q R S T U

A B C D E F G H I J K L

saved date:

Page name:

Motor Control Interface

From Speed Regulator

Ovr_SpTq

Back to Overview

NAVIGATION

SReg

Torque Command

Motoring & Generating Torque Limit Select

Torque

Compen-

sation

Current Command

Current Limit Select

Motoring &

Generating Limit

Steering Control

Ovr_MCtrl

To Motor Control

Current

Magnitude

Limit

Pullout Limit

Adjustment

and

Power-Dip

Clamp

Control

DC Bus

Regen Control

can reduce

Generating

Limit

Not Used

Not Used

Not Used

From Sequencer

GenSeq_5

To Droop Feedback

Droop

0

0

0

Flux Adjust Select

Not Used

Ovr_MCtrl

To Motor Control

Jun 06, 2000ISD1

Current limit

Torque ref pre limit

Torque current limit

Torque lim 2 sel

Force False

Torque lim 2 sel

Force False

Torque lim 2 sel

Force False

Motoring torque lim

Regen torque limit

Torque ref post lim

Motoring torque lim1

1 pu

Motoring torque lim2

1 pu

Regen torque lim 1

1 pu

Regen torque lim 2

1 pu

Trq cur ref pre lim

Current limit 1

1 pu

Current limit 2

1 pu

Torque current ref

Motor rated current

<No Value> Amps

Adj mtr trq lim sel

Unused float

Adj gen trq lim sel

Unused float

100% Motor torque

Adj cur lim ref sel

Unused float

Motor rated power

<No Value> KW

Motor rated rpm

<No Value> RPM

Flux current, avg

Adj mtr trq lim sel

Adj gen trq lim sel

Adj cur lim ref sel

Dc source

Rectifier without DB

Torque enable req

Ix command pos limit

Torque cmd neg limit

Ix command neg limit

Torque cmd pos limit

Flux ref ratio setpt

1

Flux ref ratio sel

Unused float

Flux ref ratio sel

Flux ref ratio