Specification Sheet

S-5582.B rev.0708

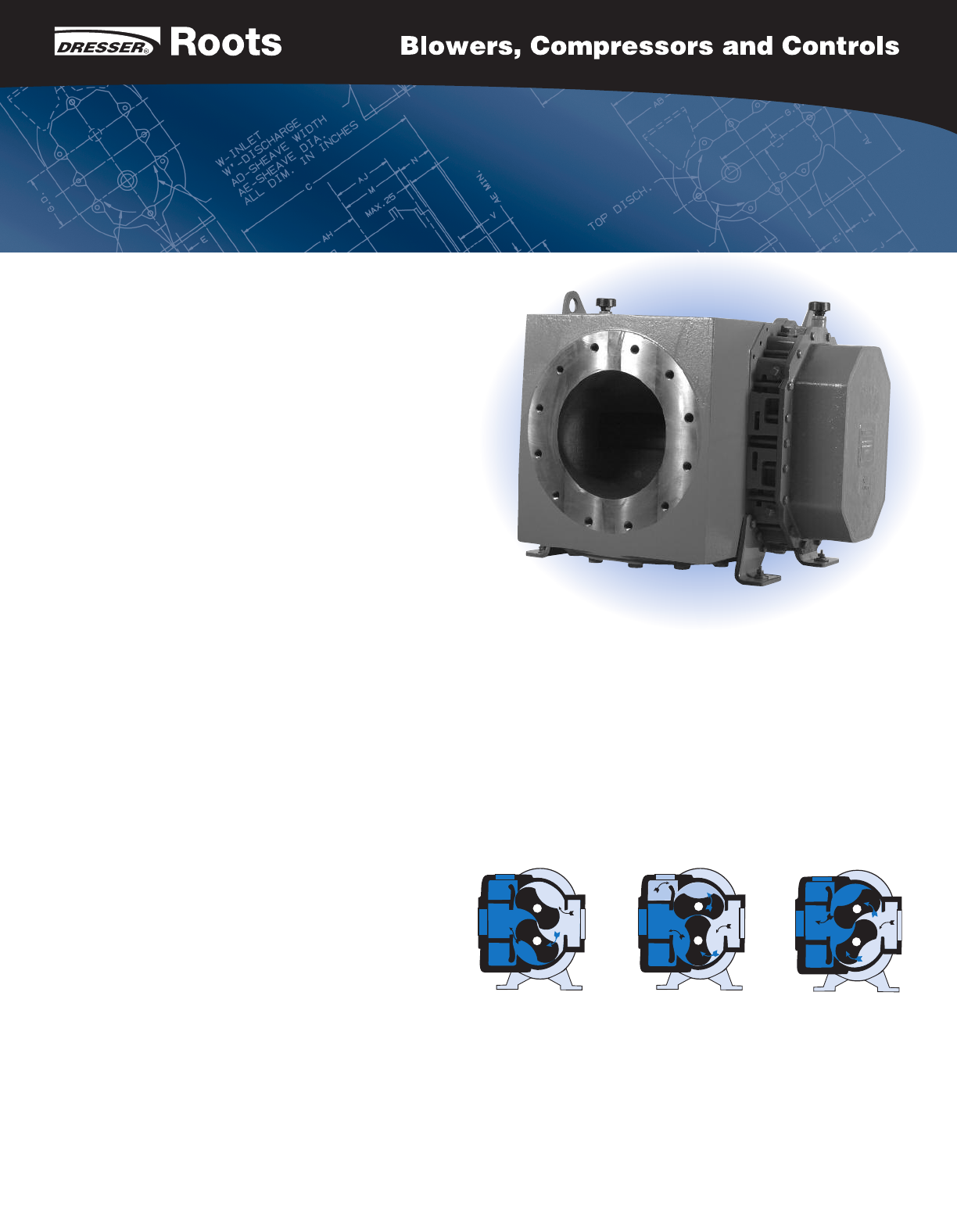

BASIC DRY VACUUM PUMP DESCRIPTION

ROOTS™ DVJ WHISPAIR™ dry exhausters have an

exclusive discharge jet plenum design which allows

cool, atmospheric air to flow into the cylinder. This

unique design permits continuous operation at

vacuum levels to blank-off with a single stage unit.

Standard dry exhausters are limited to approx.

16” Hg vacuum because operation at higher vacuum

levels can cause extreme discharge temperatures

resulting in casing & impeller distortion and possible

seizure. The DVJ vacuum exhauster’s integral cooling

design eliminates the problems associated with high

temperatures at vacuum levels beyond 16” Hg.

DVJ WHISPAIR™ exhausters are heavy-duty units

with integral-shaft ductile iron impellers. The casing,

headplates, gear cover and drive end cover are grey

iron. Carburized and ground alloy steel spur timing

gears are taper mounted on the shafts, secured with a

locknut. Cylindrical roller bearings are splash lubricated

at both the gear end and drive end. Piston rings reduce

air leakage through the headplate bores and lip-type oil

seals prevent lubricants from entering the air chamber.

Rugged steel mounting feet permit infield adaptability

to either vertical or horizontal installation requirements.

ROOTS™ DVJ WHISPAIR™ exhausters can be

arranged to operate in two and three stage systems

to achieve vacuum levels down to 1 Torr.

WARRANTY PERIOD

Twelve (12) months from date of original unit

start-up or 18 months from date of original

shipment, whichever occurs first.

OPERATING PRINCIPLE

DESIGN AND CONSTRUCTION FEATURES

1. Rigid cast iron cylinder and headplates

2. Anti-friction cylindrical roller bearings

3. Splash lubricated spur timing gears

4. Inlet and discharge connections in standard

pipe sizes

5. Involute profile ductile iron impellers

POSITION 3

POSITION 2POSITION 1

Position 1: Incoming air is trapped between the impellers. Simultaneously,

pressurized air is being discharged. Position 2: As the upper impeller passes

the jet plenum, cooled, pressurized air flows into the space between the

impeller and cylinder. This cools the trapped air, helps control thermal growth

and allows higher discharge pressures. Position 3: The trapped air is then

moved into the discharge flange (left). Backflow is reduced, resulting in lower

operating noise level and reduced shock loading on the impellers.

SPECIFICATIONS

ROOTS

™

DVJ WHISPAIR

™

Dry Vacuum Exhausters

Frame 721J