Installation Guide

44

2. Firmly touch a clean, unpainted, metal surface of the

furnace away from the control. Any tools held in a person’s

hand during grounding will be discharged.

3. Service integrated control module or connecting wiring

following the discharge process in step 2. Use caution not

to recharge your body with static electricity; (i.e., do not

move or shuffle your feet, do not touch ungrounded objects,

etc.). If you come in contact with an ungrounded object,

repeat step 2 before touching control or wires.

4. Discharge your body to ground before removing a new

control from its container. Follow steps 1 through 3 if

installing the control on a furnace. Return any old or new

controls to their containers before touching any ungrounded

object.

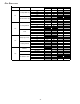

DIAGNOSTIC CHART

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

PERFORMING

ANY

SERVICE

OR

MAINTENANCE

.

WARNING

Refer to the Troubleshooting Chart in the back of this manual

for assistance in determining the source of unit operational prob-

lems. The dual 7-segment LED display will display an error code

that may contain a letter and number. The error code may be

used to assist in troubleshooting the unit.

RESETTING FROM LOCKOUT

Furnace lockout results when a furnace is unable to achieve igni-

tion after three attempts during a single call for heat. It is char-

acterized by a non-functioning furnace and a E

0 code displayed

on the dual 7-segment display. If the furnace is in “lockout”, it

will (or can be) reset in any of the following ways.

1. Automatic reset. The integrated control module will

automatically reset itself and attempt to resume normal

operations following a one hour lockout period.

2. Manual power interruption. Interrupt 115 volt power to

the furnace.

3. Manual thermostat cycle. Lower the thermostat so that

there is no longer a call for heat for 1 -20 seconds then

reset to previous setting.

NOTE: If the condition which originally caused the lockout still

exists, the control will return to lockout. Refer to the

Troubleshooting Chart for aid in determining the cause.

M

AINTENANCE

T

O

AVOID

ELECTRICAL

SHOCK

,

INJURY

OR

DEATH

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

PERFORMING

ANY

MAINTENANCE

. I

F

YOU

MUST

HANDLE

THE

IGNITER

,

HANDLE

WITH

CARE

. T

OUCHING

THE

IGNITER

ELEMENT

WITH

BARE

FINGERS

,

ROUGH

HANDLING

OR

VIBRATION

COULD

DAMAGE

THE

IGNITER

RESULTING

IN

PREMATURE

FAILURE

. O

NLY

A

QUALIFIED

SERVICER

SHOULD

EVER

HANDLE

THE

IGNITER

.

WARNING

ANNUAL INSPECTION

The furnace should be inspected by a qualified installer, or ser-

vice agency at least once per year. This check should be per-

formed at the beginning of the heating season. This will ensure

that all furnace components are in proper working order and

that the heating system functions appropriately. Pay particular

attention to the following items. Repair or service as necessary.

• Flue pipe system. Check for blockage and/or leakage.

Check the outside termination and the connections at

and internal to the furnace.

• Heat exchanger. Check for corrosion and/or buildup

within the heat exchanger passageways.

• Burners. Check for proper ignition, burner flame, and

flame sense.

• Drainage system. Check for blockage and/or leakage.

Check hose connections at and internal to furnace.

• Wiring. Check electrical connections for tightness and/

or corrosion. Check wires for damage.

• Filters.

FILTERS

T

O

ENSURE

PROPER

UNIT

PERFORMANCE

,

ADHERE

TO

THE

FILTER

SIZES

GIVEN

IN

THE

RECOMMENDED

M

INIMUM

F

ILTER

S

IZE

T

ABLE

OR

S

PECIFICATION

S

HEET

APPLICABLE

TO

YOUR

MODEL

.

CAUTION

FILTER MAINTENANCE

Improper filter maintenance is the most common cause of inad-

equate heating or cooling performance. Filters should be cleaned

(permanent) or replaced (disposable) every two months or as

required. When replacing a filter, it must be replaced with a

filter of the same type and size.

FILTER REMOVAL

Depending on the installation, differing filter arrangements can

be applied. Filters can be installed in either the central return

register or a side panel external filter rack (upflow only). A

media air filter or electronic air cleaner can be used as an alter-

nate filter. Follow the filter sizes given in the Recommended

Minimum Filter size table to ensure proper unit performance.