GVZC20 Service Manual

TROUBLESHOOTING

98

(*1) This message displayed when using the CTKO4 thermostat.

(*2) This specication of *VZC20**1 or earlier model are dierent from this specication. For details, see the service manual that matches the major revisoin of model name.

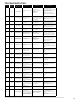

Fault Code

Control Board

LED Display

Transmitted Climate

Talk Message

Thermostat Fault Probable Causes Corrective Actions

22 E22 HI DISCH TEMP

This error indicates the equipment

is experiencing frequent high

discharge temperature faults.

Discharge thermistor is not put on

correct position.

● Discharge thermistor inoperable or

improperly connected

● Discharge thermistor is put on

incorrect position or off

● Low refrigerant charge

● Overcharge

● Faulty compressor

● Check discharge thermistor resistance and

connections; Repair/replace as needed

● Check discharge thermistor position

● Check refrigerant charge level; Adjust if

needed

● Check the compressor; Repair/replace if

needed

23 E23 DISCH TEMP FAIL

The control has detected that the

Discharge Temperature Sensor is

out of range.

● Discharge thermistor inoperable or

improperly connected

● Check discharge thermistor resistance and

connections; Repair/replace as needed

24 E24 HPS OPEN

The high pressure switch is open.

● High pressure switch (HPS)

inoperable

● Check resistance on HPS to verify operation;

Replace if needed

25

E25

AIR SENSOR FLT

The outdoor air temperature

sensor is open or shorted.

● Faulty outdoor thermistor sensor or

disconnect

● Inspect and test sensor; Replace sensor if

needed

26

E26

PRESSURE SENSOR

The control determines that the

pressure sensor is not reacting

properly.

● Low pressure sensor inoperable or

not properly connected

● Check the connection to low pressure

sensor; Repair/replace if needed

27 E27 COIL TEMP FAIL1

The control detects that the

Outdoor Defrost Sensor is out of

range.

● Outdoor defrost thermistor inoperable

or not properly connected

● Check the connection to OD defrost

thermistor; Repair as needed

28 E28 COIL TEMP FAIL2

The control has detected that the

Outdoor Coil Temperature Sensor

is out of range.

● Outdoor coil thermistor inoperable or

not properly connected

● Check the connection to OD coil thermistor;

Repair/replace if needed

29 E29 LIQ TEMP FAIL

The control has detected that the

Liquid Temperature Sensor is out

of range.

● Liquid thermistor inoperable or not

properly connected

● Check the connection to liquid thermistor;

Repair/replace if needed

30 E30 OD CTRL FAIL3

Indicates the control board may

need to be replaced.

● Wiring to control board disconnected

● Faulty control board

● Noise

● Check wiring to control board; Repair as

needed

● Replace control board if necessary

31 E31 HI LEAK CURRENT

The control has detected high

leakage current (high voltege).

● Improper ground

● Faulty compressor

●Check ground screws/lugs and wiring;

Repair/replace if needed

● Check the compressor; Repair/replace if

needed

32*

2

E32 HI TEMP CTRL1

This error indicates the equipment

is experiencing high temperature

faults on the outdoor control board.

● Ambient air conditions too high

● Cooling bracket screw(s) missing or

not properly fastened (2-4 ton only)

● No or poor thermal grease coating

between cooling plumbing and cooling

bracket on control board (2-4 ton only)

● Outdoor fan low speed (5 ton only)

● No flow or limited flow through control

board cooling circuit (potential

restriction in line or low refrigerant) (2-4

ton only)

● Stop valve not completely open (2-4

ton only)

● Cycle power; re-try during usable ambient

temperature range

● Verify cooling bracket screws in place and

secure; Secure fasteners as needed (2-4 ton

only)

● Check thermal grease inside cooling bracket

on control board; Apply additional grease as

needed

● Check outdoor fan motor & wiring;

Repair/replace if needed (5 ton only)

● Check for restriction in line

● Check refrigerant charge level; Adjust if

needed (2-4 ton only)

● Check the opening of stop valve, should be

full open;

Repair/replace if needed (2-4 ton only)

33*

2

- HI TEMP CTRL2

This error indicates the equipment

is experiencing high temperature

faults on the outdoor control board.

Control has determined continued

operation is acceptable. This

indicates they may be a problem

with the equipment.

● Ambient air conditions too high

● Cooling bracket screw(s) missing or

not properly fastened (2-4 ton only)

● No or poor thermal grease coating

between cooling plumbing and cooling

bracket on control board (2-4 ton only)

● Outdoor fan low speed (5 ton only)

● No flow or limited flow through control

board cooling circuit (potential

restriction in line or low refrigerant) (2-4

ton only)

● Stop valve not completely open (2-4

ton only)

● Cycle power; re-try during usable ambient

temperature range

● Verify cooling bracket screws are in place

and secure; Secure fasteners as needed (2-4

ton only)

● Check thermal grease inside cooling bracket

on control board; Apply additional grease as

needed

● Check outdoor fan motor & wiring;

Repair/replace if needed (5 ton only)

● Check for restriction in line

● Check refrigerant charge level; Adjust if

needed (2-4 ton only)

● Check the opening of stop valve - it should

be fully

open; Repair/replace if needed (2-4 ton only)

34 E34 CURRENT SPIKE

Board detected a high current

condition. This indicates the

potential for a short circuit.

● Current spike in supply

● Stop valve not completely open

● The compressor wire is lost phase

● Faulty control board

● Faulty compressor

● Check power supply for in-rush current

during start-up or steady state operation

● Check the opening of stop valve, should be

full open; Repair/replace if needed

● Check the wire between control board and

compressor

● Replace control board if necessary

● Check the compressor; Repair/replace if

needed