User's Manual

22 308148

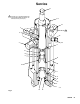

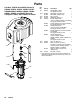

Service

Reassembly

1. If it was necessary to remove the ball guide (9)

from the displacement rod (1), place the flats of

the rod in a vise. Apply anti-seize lubricant 222955

to the threads and mating faces of the rod and the

ball guide. Screw the ball guide onto the rod, hand

tight. Remove from the vise. See Fig. 8.

2. Place the female gland (13*) on the piston seat

housing (12). Install the five v-packings (P) one at

a time with the lips facing up. Refer to pages 30

and 32 for the correct packing order for your

pump. Install the male gland (11*).

NOTE: To convert the pump to a different packing

material, see pages 30 and 32.

NOTE: Service Tool 109507 is available as an acces-

sory. The tool fits over the top of the displacement rod

(1), making it easier to apply a 24 inch adjustable

wrench or 3/4 in. drive socket when connecting the rod

to the piston assembly.

3. Apply anti-seize lubricant 222955 to the threads

and mating faces of the ball guide (9) and piston

seat housing (12). Place the flats of the piston seat

housing in a vise. Place the ball (10) on the piston

seat. Screw the assembled rod (1) and ball guide

(9) onto the piston assembly hand tight, then

torque to 459–481 N.m (338–354 ft–lb).

4. Use an arbor press to reinstall the rod (1) into the

cylinder (7), as follows. (The cylinder is symmetri-

cal, so either end may face up.) Lubricate the

piston packings (P). With the piston end facing

down, lower the rod into the cylinder. Start the

piston into the cylinder as much as possible, then

drive the rod and piston the rest of the way into the

cylinder with the arbor press.

CAUTION

To reduce the possibility of costly damage to the rod

(1) and cylinder (7), always use an arbor press to

drive the rod into the cylinder, and be sure to place

the cylinder on a soft block of wood. Never use a

hammer to drive the rod.

5. Lubricate the o-ring (27*) and seal (6*). Install the

o-ring on the intake seat housing (15). Install the

intake seat housing (15), intake ball (16), ball guide

(14), and seal (6*) in the intake housing (17). Set

the intake housing all the way into the vise.

6. Place the cylinder (7) on the intake housing (17).

Tap on the top of the displacement rod (1) with a

rubber mallet, to seat the cylinder.

7. Lubricate the throat packings (T). Place the male

gland (29*) into the outlet housing (19). Install the

five v-packings one at a time with the lips facing

down. Refer to pages 30 and 32 for the correct

packing order for your pump. Install the female

gland (25*).

NOTE: To convert the pump to a different packing

material, see pages 30 and 32.

8. Lubricate the threads of the packing nut (3), and

loosely install it in the outlet housing (19).

9. Lubricate the seal (6*) and install it in the bottom of

the outlet housing (19). Set the outlet housing on

top of the cylinder (7). Apply thread lubricant to the

six long cap screws (20). Install the washers (33, if

present) and cap screws through the outlet hous-

ing (19) and thread them loosely by hand into the

intake housing (17). Tighten the cap screws oppo-

sitely and evenly, using a socket wrench, then

torque to 244–264 N.m (180–195 ft–lb).

10. Screw the housing valve (34) into the valve hous-

ing. Torque to 30–28 N.m (22–28 ft-lb).

NOTE: It is not ordinarily necessary to remove the

outlet fitting (4) and o-ring (5*). However, if they were

replaced because of damage, lubricate the o-ring and

place it on the fitting. Screw the fitting into the outlet

housing (19). Torque to 156–171 N.m (115–126 ft–lb).

11. Reconnect the displacement pump to the air motor

as explained on page 18.