Manual

19

Service

4. Loosen but do not remove the diaphragm shaft bolts

(107), using a 15 mm socket wrench (1” on stainless

steel models) on both bolts.

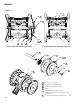

5. Unscrew one bolt from the diaphragm shaft (24) and

remove the o-ring (108), fluid side diaphragm plate

(105), TeflonR diaphragm (403, used on TeflonR

models only), diaphragm (401), and air side diaphragm

plate (104). See Fig. 13.

6. Pull the other diaphragm assembly and the diaphragm

shaft (24) out of the center housing (1). Hold the shaft

flats with a 19 mm socket wrench, and remove the bolt

(107) from the shaft. Disassemble the remaining

diaphragm assembly.

7. Inspect the diaphragm shaft (24) for wear or scratches.

If it is damaged, inspect the bearings (19) in place. If

the bearings are damaged, refer to page 21.

8. Reach into the center housing (1) with an o-ring pick

and hook the u-cup packings (402), then pull them out

of the housing. This can be done with the bearings (19)

in place.

9. Clean all parts and inspect for wear or damage. Re-

place parts as needed.

Reassembly

1. Install the shaft u-cup packings (402*) so the lips face

out of the housing (1). Lubricate the packings. See Fig.

13.

2. Install the diaphragm assembly on one end of the shaft

(24) as follows:

a. Install the o-ring (108*) on the shaft bolt (107).

b. Install the fluid side diaphragm plate (105) on the

bolt so the rounded side faces the diaphragm

(401).

c. On TeflonR models only, install the TeflonR

diaphragm (403*). Make certain the side marked

AIR SIDE faces the center housing (1).

d. Install the diaphragm (401*) on the bolt. Make

certain the side marked AIR SIDE faces the center

housing (1).

e. Install the air side diaphragm plate (104) so the

rounded side faces the diaphragm (401). This plate

is used on all models, and is stamped with its part

number.

f. Apply medium-strength (blue) LoctiteR or equiv-

alent to the bolt (107) threads. Screw the bolt into

the shaft (24) hand tight.

3. Grease the length and ends of the diaphragm shaft (24),

and slide it through the housing (1).

4. Assemble the other diaphragm assembly to the shaft as

explained in step 2.

5. Hold one shaft bolt (107) with a wrench and torque the

other bolt to 20–25 ft-lb (27–34 N.m) at 100 rpm

maximum.

6. Align the fluid covers (101) and the center housing (1)

so the arrows (A) on the covers face the same direction

as the air valve (B). Apply medium-strength (blue)

LoctiteR or equivalent to the threads of the screws

(106). Secure the covers with the screws handtight.

See Fig. 12. Using a 10 mm socket wrench, torque the

screws oppositely and evenly to 120–150 in-lb (14–17

N.m).

7. Reassemble the ball check valves and manifolds as

explained on page 17.