Service Manual

Super Free Match

Service Manual

INSTALLATION

56

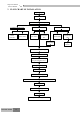

1.2 Key Points of Installation

Installation Procedures Description and Acceptance Criteria

Material Selection and Equipment Inspection

◆ The materials specified on the engineering drawing shall be

purchased as specified (e.g. copper tube, thermal insulation

tube, PVC pipe, power cables, air switch, etc).

◆ The materials not specified on the engineering drawing shall

be purchased according to the actual quantity of works (e.g.

hanger frame, cable duct, etc).

◆ Check if the outdoor unit, indoor unit, BU modules,

communication wires and accessories are complete.

Installation of

indoor unit

Communica

tion wire

Connection

◆ The power cables shall be separated from communication

wires at a least distance of 2cm.

◆ To avoid breaking the communication wires, please do not use

strong force.

◆ For multiple units, please mark them properly.

◆ Switch on the unit, and ensure there is no display of

“Communication Wire Error E6”.

Address dial

code

◆ Each BU module and indoor unit under the same system has a

unique address dial code.

◆ The wired controller and its corresponding indoor unit have

the same address dial code.

Remote Control

◆ Select the remote control mode.

◆ The centralized controller and communication module shall be

installed free from the source of interference.

Power cord

◆ The power cable must meet the specifications.

Drainage

Pipe

Installation

◆ The PVC pipes must meet the specifications.

◆ A specific gradient must be provided along the water flow

direction.

◆ Carry out water detection after installation.

◆ Carry out thermal insulation to the drainage pipe only after the

water detection is accepted.

Thermal

insulation

◆ The thermal insulation tube must meet the specifications.

◆ Seal between the thermal insulation pipes to avoid air entry.

Installation of

connection pipes

Welding

◆ The copper tube must meet the specifications.

◆ Ensure it is dry and clean inside the tube.

◆ Make sure to charge nitrogen as required for protection when

welding the tubes.

◆ Please keep to the welding process and ensure the system free

of leakage.

◆ Add a dual-way filter on liquid pipe side

◆ For multiple systems, please mark them properly.

◆ Carry out leakage detection under pressure after welding.

Purge and make leakage

detection under pressure

◆ Purge the system clean.

◆ Keep the pressure for 24 hours

◆ Except for the influence by temperature, it is deemed