Service Manual

Table Of Contents

- 目录

- 第一部分 产品篇

- 第二部分 控制篇

- CONTROL

- 1 OPERATION FLOWCHART

- 2 WIRELESS REMOTE CONTROLLER

- 3 WIRED CONTROLLER

- 4 OPERATION INSTRUCTION OF SPECIAL FUNCTIONS

- 4.1 Setting of Filter Clean Reminder Function

- 4.2 Low Temperature Drying Function

- 4.3 Lock Function

- 4.4 Memory Function

- 4.5 Door Control Function/Human Sensitive Function

- 4.6 Switch between Fahrenheit and Centigrade

- 4.7 Enquiry of Ambient Temperature

- 4.8 Enquiry of Historical Malfunction

- 4.9 Debugging Function

- 4.9.1 Setting ambient temperature sensor (dual ambient temperature sensors function)

- 4.9.2 Selecting three speeds in high speed and three speeds in low speed of indoor fan motor

- 4.9.3 Displaying setting of freeze protection error code

- 4.9.4 Setting refrigerant lacking protection function

- 4.9.5 Selecting blowing residual heating of indoor unit

- 4.9.6 Mode selecting of compressor electric heating belt

- 4.9.7 Selecting low-power consumption mode

- 4.9.8 Selecting door control function

- 4.9.9 Selecting human sensitive function

- 4.9.10 Selecting long-distance monitoring or centralized controller

- 4.9.11 Selecting fan mode of indoor fan motor

- 4.9.12 Selecting compensation of temperature sensor at air return

- 5 INSTALLATION OF WIRED CONTROLLER

- 6 TROUBLESHOOTING

- 7 CENTRALIZED CONTROLLER

- 7.1 Smart Zone Controller

- 7.2 Additional Special Functions

- 7.2.1 Door control function

- 7.2.2 Human sensitive function

- 7.2.3 MODBUS interface

- 7.2.4 Connect to interface of centralized controller:

- 7.2.5 Light board control:

- 7.2.6 Malfunction output of relay:

- 7.2.7 Reserved fresh air valve interface for duct type unit

- 7.2.8 Interface of anion generator

- 7.2.9 Chassis electric heating belt of outdoor unit is optional

- CONTROL

- 第三部分 安装篇

- INSTALLATION

- 1 INDOOR UNIT INSTALLATION

- 1.1 Installation of Duct Type

- 1.2 Installation of Floor Ceiling Type

- 1.3 Installation of Cassette Type

- 1.3.1 Before Installation

- 1.3.2 Installation Site

- 1.3.3 Installing the Main Body Unit

- 1.3.4 Installing the Suspension Bolts

- 1.3.5 Leveling

- 1.3.6 The Panel Installation

- 1.3.7 Dimension Data

- 1.3.8 Installation of Drain Piping

- 1.3.9 Installing the Drain Pipes

- 1.3.10 Precautions When Doing Riser Piping Work

- 1.3.11 Testing of Drain Piping

- 2 OUTDOOR UNIT INSTALLATION

- 3 REFRIGERATION PIPING WORK

- 3.1 Refrigeration Piping Work Procedures and Caution in Connecting

- 3.2 Specification of Connection Pipe

- 4 ELECTRIC WIRING WORK

- 1 INDOOR UNIT INSTALLATION

- INSTALLATION

- 第四部分 维护篇(上)4.1~4.3

- 第四部分 维护篇(中)4.4拆装

- 第四部分 维护篇(下)4.5爆炸图及清单

U-Match Series DC Inverter Service Manual

95

MAINTENANCE

1 TROUBLE TABLE

1.1 Main Control Malfunction

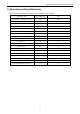

Table 4-1-1 Fault Display on Indoor Wired Controller

No.

Error code

Malfunction

name

Origin of

malfunction

signal

Control description

1

E1

High pressure

protection

High pressure

switch

When outdoor unit detects the high pressure switch is cut off for

3s successively, high pressure protection will occur. All the loads

(except the 4-way valve in heating mode) will be switched off. In

this case, all the buttons and remote control signals except

ON/OFF button will be disabled and cannot be recovered

automatically. Switch off the unit or re-energize the unit after

cutting off power to eliminate this protection.

2

E2

Freeze protection

Indoor

evaporator

temperature

sensor

If detecting that the evaporator temperature is lower than

protective temp. value after the unit has been running for a

period of time under cooling or dry mode, the unit will report this

fault, in which case the compressor and outdoor fan motor will be

stopped. The unit will not run until evaporator temperature is

higher than the protective temp. value and the compressor is

stopped for 3min.

3

E3

Low pressure

protection

Low pressure

switch

If it is detected within 30s successively that the low-pressure

switch is cut off under ON or standby state, the unit will report low

pressure protection. If the fault occurs successively 3 times

within 30min, the unit cannot be recovered automatically.

Refrigerant

lacking protection

If the unit reports system refrigerant lacking within 10min after

turning on the unit, the unit will stop operation. If the fault occurs

successively 3 times, the unit cannot be recovered automatically.

Refrigerant

recycling mode

If enter refrigerant recycling mode through special operation, E3

will be displayed. After exiting refrigerant recycling mode, the

code will disappear.

4

E4

Compressor high

discharge

temperature

protection

Compressor

discharge

temperature is

high

If outdoor unit detects that the discharge temperature is higher

than protective temp. value, the unit will report high discharge

temperature protection. If the protection occurs over 6 times, the

unit cannot be recovered automatically. Switch off the unit or

re-energize the unit after cutting off power to eliminate this

protection.

5

E6

Communication

malfunction

Communication

between indoor

and outdoor main

board

If the outdoor unit does not receive data from indoor unit,

communication malfunction will be reported. If there is

communication abnormity between display board and indoor unit,

communication malfunction will be reported too.

6

E8

Malfunction of

indoor fan motor

Indoor fan motor

If the indoor unit does not receive signal from indoor fan motor for

30s successively when the fan motor is operating, indoor fan

motor malfunction will be reported. In this case, the unit can

automatically resume operation after stopping. If the malfunction

occurs 6 times within one hour, the unit cannot be recovered

automatically. Switch off the unit or re-energize the unit after

cutting off power to eliminate this malfunction.