User Manual

Table Of Contents

- Table of Contents

- Using the Manual

- Contents of Kit

- Other Items Needed (not included in the kit)

- Additional Required Equipment

- Additional Required Tools and Adhesives

- Optional Hangar 9 1/3 Scale Hardware Package

- Servo Selection

- Before Starting Assembly

- Warning

- Warranty Information

- Section 1 - Aileron Servo Installation

- Section 2 - Aileron Control Horn Installation

- Section 3 - Hinging and Sealing the Control Surfaces

- Section 4 - Sealing the Hinge Gaps

- Section 5 - Aileron Linkage Installation

- Section 6 - Wing Tube Installation

- Section 7 - Rudder and Elevator Servo Installation

- Section 8 - Elevator Linkage Installation

- Section 9 - Rudder Linkage Installation

- Section 10 - Landing Gear Installation

- Section 11 - Wheel Pant Installation

- Section 12 - Tail Wheel Installation

- Section 13 - Receiver, Battery and Fuel Tank Installation

- Section 14 - Mounting the Engine and Cowl

- Section 15 - Hatch Assembly

- Section 16 - Balancing the Model

- Section 17 - Radio Setup

- Section 18 - Control Throws

- Preflight at the Field

- Setup and Flying

- Extra 330S - 3D at its Best

- 2003 Official AMA National Model Aircraft Safety Code

Section 3 – Hinging and Sealing the Control Surfaces

11

Step 3

Allow the epoxy to fully cure for at least 6 hours.

When cured, work each hinge throughout its full

motion several times using your hands. This will

break free any epoxy that may have found its way into

the hinge joint. Move the hinge throughout its full

travel until no resistance is felt. This may take as

many as 40 or 50 times.

Step 4

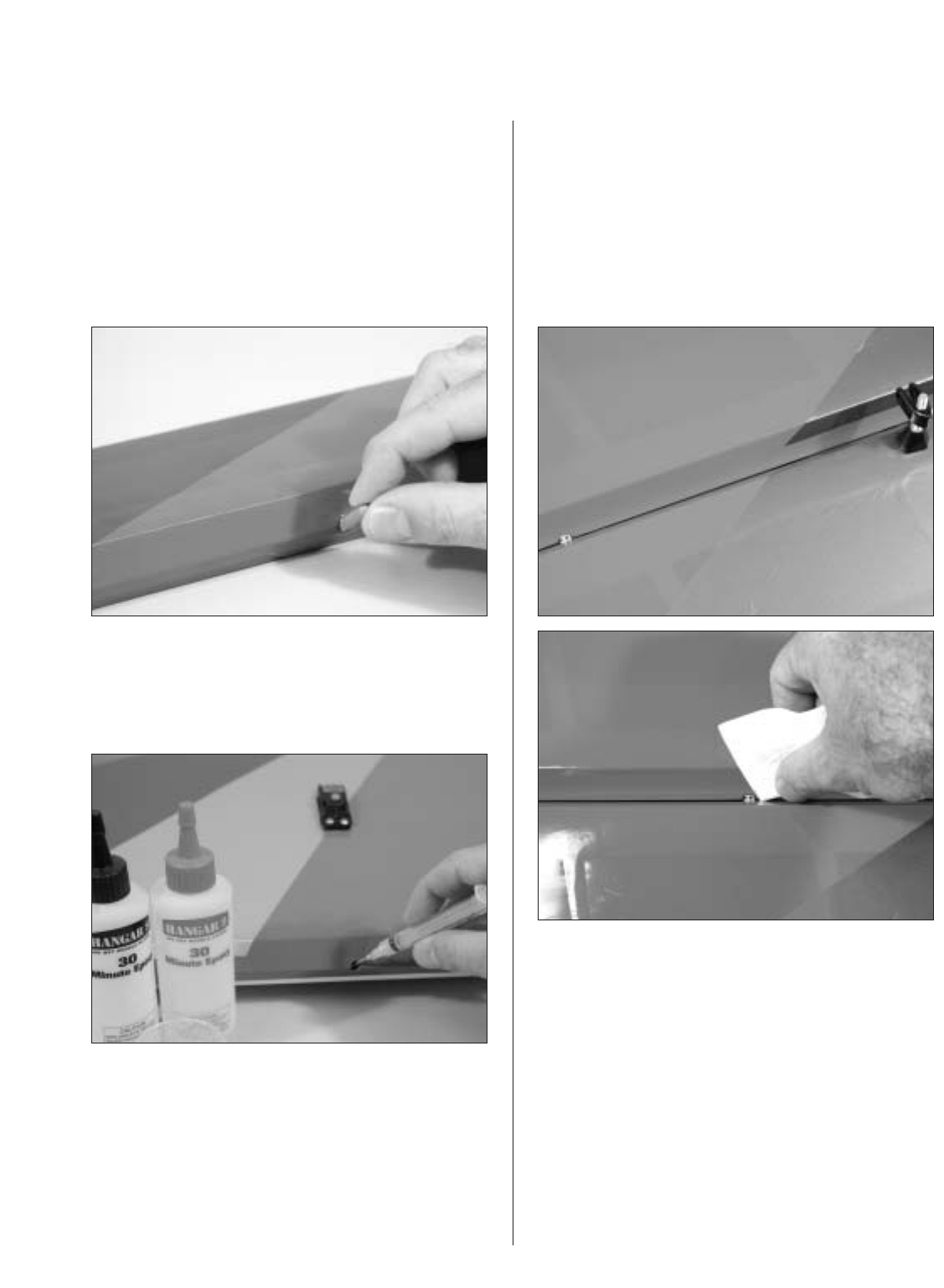

Mix 1 ounce of 30-minute epoxy. Using a syringe or

toothpick, place a sufficient amount of epoxy in each

of the hinge pockets in one wing panel.

Step 5

Carefully attach the aileron to the wing, making sure

the hinges are inserted in their respective hinge

pockets. Press the aileron and wing together such

that less than a 1/64" hinge line gap exists between

the aileron and wing. The bevels should virtually

touch. Use a paper towel and rubbing alcohol to wipe

away any visible epoxy around the hinges.

Step 6

Double-check the hinge gap and allow the epoxy

to fully cure for at least 6 hours. Now is a good

time to repeat Steps 1 through 5 for the remaining

wing panel and aileron.