User Manual

Table Of Contents

- Table of Contents

- Using the Manual

- Contents of Kit

- Other Items Needed (not included in the kit)

- Additional Required Equipment

- Additional Required Tools and Adhesives

- Optional Hangar 9 1/3 Scale Hardware Package

- Servo Selection

- Before Starting Assembly

- Warning

- Warranty Information

- Section 1 - Aileron Servo Installation

- Section 2 - Aileron Control Horn Installation

- Section 3 - Hinging and Sealing the Control Surfaces

- Section 4 - Sealing the Hinge Gaps

- Section 5 - Aileron Linkage Installation

- Section 6 - Wing Tube Installation

- Section 7 - Rudder and Elevator Servo Installation

- Section 8 - Elevator Linkage Installation

- Section 9 - Rudder Linkage Installation

- Section 10 - Landing Gear Installation

- Section 11 - Wheel Pant Installation

- Section 12 - Tail Wheel Installation

- Section 13 - Receiver, Battery and Fuel Tank Installation

- Section 14 - Mounting the Engine and Cowl

- Section 15 - Hatch Assembly

- Section 16 - Balancing the Model

- Section 17 - Radio Setup

- Section 18 - Control Throws

- Preflight at the Field

- Setup and Flying

- Extra 330S - 3D at its Best

- 2003 Official AMA National Model Aircraft Safety Code

14

Section 5 – Aileron Linkage Installation

Required Parts

• Aluminum servo arms (4)

• Control horn ball ends (4)

• 4

1

/

2

" 4-40 linkage (4)

Required Tools and Adhesives

• Phillips screwdriver (small)

• Threadlock

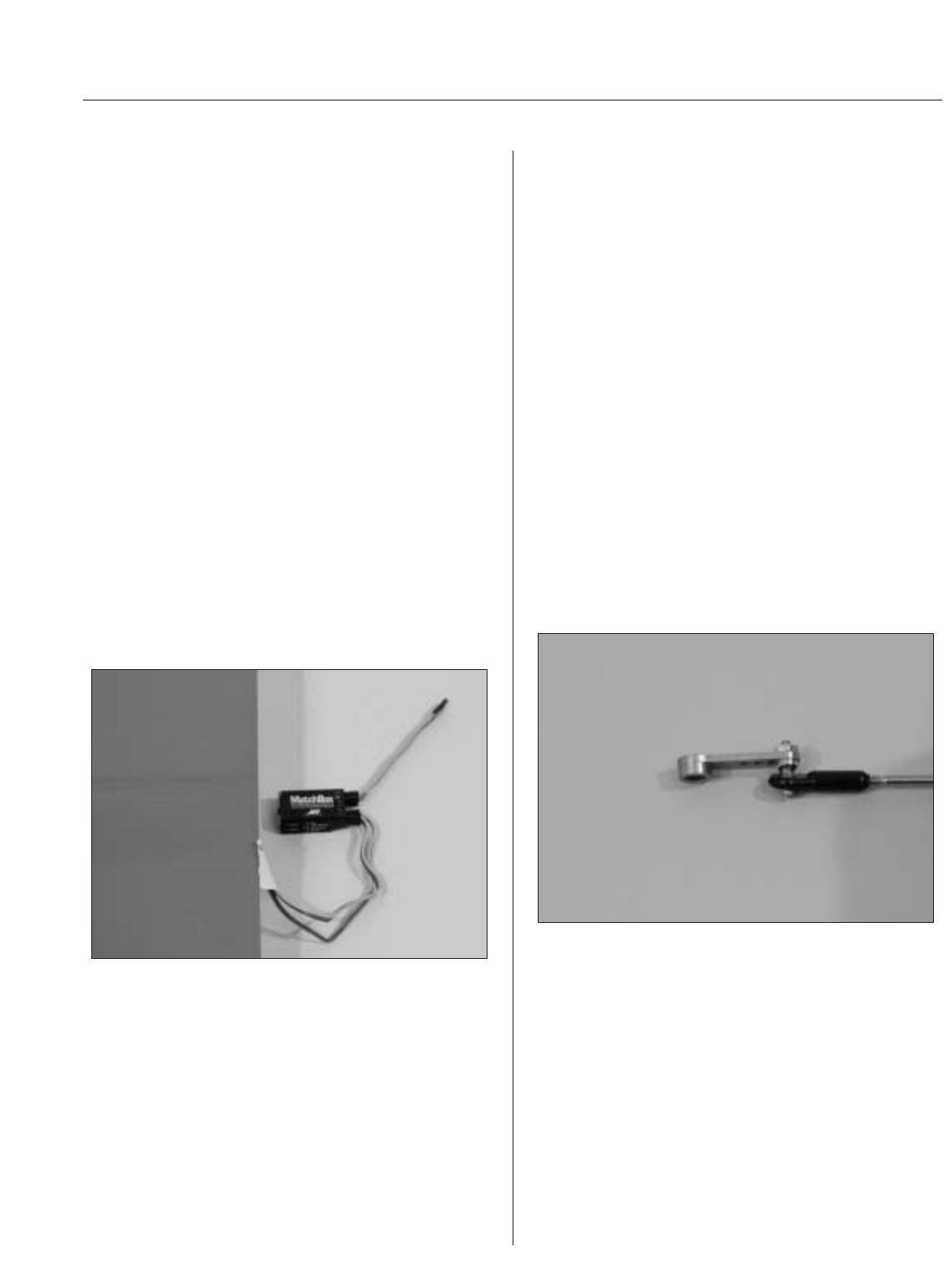

MatchBox Option: To simplify the installation of

the aileron servo linkages, you may want to use the

JR™ MatchBox™ servo matching/power system

(JRPA900). Four MatchBoxes would be used in this

application—one for each wing panel, one for the

rudder and one for the elevator servo configuration.

The MatchBox allows easy adjustment of the servo’s

center and endpoints, making radio setup a snap.

You can also use a separate battery to run the

Matchbox, reducing the load on the flight battery

powering the receiver.

Step 1

Screw a 4-40 ball link 5 to 6 turns onto each end of

a 4

1

/

2

" long 4-40 linkage. Adjust the linkage length

until the hole in the ball link aligns with the outer

hole in the servo arm when the aileron is neutral

and the servo arm is centered.

Note: Hangar 9

®

Titanium Pro-Links feature

right-hand threads on one end and left- hand

threads on the other, allowing for easy,

accurate adjustment without disconnecting

the linkages. Consistently putting the right-

hand threads toward the servo arms on all

servos will prevent you from getting confused

as to which way to turn the linkage to lengthen

or shorten the link. Hangar 9 also offers a

Pro-Link™ Wrench (HAN3558) to make

adjustments easier.

Step 2

Using the 4-40 screws (don’t substitute a standard

screw) and nuts included in the Hangar 9 package,

attach the ball link to the outer hole in the arm from

the bottom side as shown. The sequence is screw,

tapered standoff, ball link, servo arm and nut. Don’t

forget to use threadlock.

Step 3

Attach the servo horn to the servo using the screw

provided with the servo.