Datasheet

2

Sensing and Internet of Things

Basic Board Mount Pressure Sensors, ABP Series

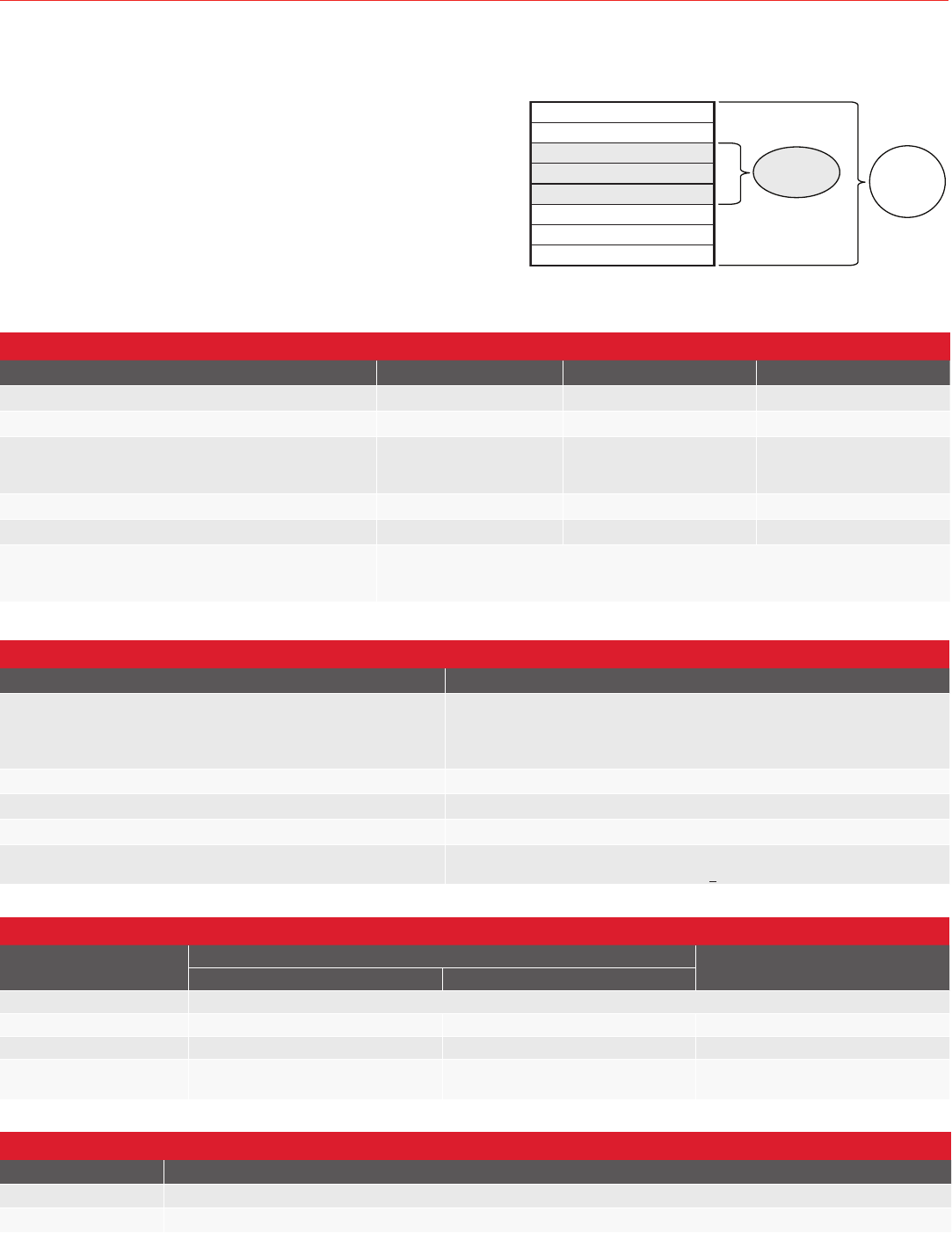

FIGURE 1. TOTAL ERROR BAND

TABLE 1. ABSOLUTE MAXIMUM RATINGS

1

CHARACTERISTIC MIN. MAX. UNIT

Supply voltage (V

supply

) -0.3 6.0 Vdc

Voltage on any pin -0.3 V

supply

+ 0.3 V

Digital interface clock frequency:

I

2

C

SPI

100

50

400

800

kHz

ESD susceptibility (human body model) 2 — kV

Storage temperature -40 [-40] 85 [185] °C [°F]

Soldering time and temperature:

lead solder temperature (DIP)

peak reflow temperature (Leadless SMT, SMT)

4 s max. at 250°C [482°F]

15 s max. at 250°C [482°F]

1

Absolute maximum ratings are the extreme limits the device will withstand without damage.

TABLE 2. ENVIRONMENTAL SPECIFICATIONS

CHARACTERISTIC

PARAMETER

Humidity:

all external surfaces

internal surfaces of Liquid Media Option (T, V, F, G)

internal surfaces of Dry Gases Option (N, D)

0 %RH to 95 %RH, non-condensing

0 %RH to 100 %RH, condensing

0 %RH to 95 %RH, non-condensing

Vibration

15 g, 10 Hz to 2 kHz

Shock

100 g, 6 ms duration

Life

1

1 million pressure cycles minimum

Solder reflow

J-STD-020-D.1 Moisture Sensitivity Level 1

(unlimited shelf life when stored at <30°C/85 %RH)

1

Life may vary depending on specific application in which the sensor is used.

TABLE 4. SENSOR PRESSURE TYPES

PRESSURE TYPE DESCRIPTION

Gage Output is proportional to the difference between applied pressure and atmospheric (ambient) pressure.

Differential Output is proportional to the difference between the pressures applied to each port (Port 1 – Port 2).

TABLE 3. WETTED MATERIALS

1

COMPONENT

PRESSURE PORT 1 (P1)

PRESSURE PORT 2 (P2)

DRY GAS OPTION LIQUID MEDIA OPTION

Ports and covers high temperature polyamide

Substrate alumina ceramic — alumina ceramic

Adhesives epoxy, silicone epoxy, silicone gel epoxy, silicone

Electronic components

silicon, glass, solder, gold,

aluminum

304 SST silicon

1

Contact Honeywell Customer Service for detailed material information.

Total Error Band (TEB) is a single specification that includes

all possible sources of error. TEB should not be confused with

accuracy, which is actually a component of TEB. TEB is the worst

error that the sensor could experience. The TEB specification

on a datasheet may be confusing. Honeywell uses the TEB

specification in its datasheet because it is the most comprehensive

measurement of a sensor’s true accuracy. Honeywell also

provides the accuracy specification in order to provide a common

comparison with competitors’ literature that does not use the

TEB specification. Many competitors do not use TEB—they simply

specify the accuracy of their device. Their accuracy specification,

however, may exclude certain parameters. On their datasheet, the

errors are listed individually. When combined, the total error (or

what would be TEB) can be significant.

Total

Error

Band

Accuracy

BFSL

All Possible Errors

Thermal Hysteresis

Thermal Effect on Offset

Thermal Effect on Span

Pressure Non-Linearity

Pressure Hysteresis

Full Scale Span

Offset

Pressure Non-Repeatibility