Submittal Sheet

VBN THREADED CONTROL BALL VALVES AND ACTUATORS

9 63-4378EFS—04

Effective C

V

For effective C

V

s for Honeywell control ball valves when used

with pipe reducers, refer to the Product Data sheet form no.

62-2648.

Application Notes

IMPORTANT

Valve sizing is important for correct system

operation. Undersized valves do not have sufficient

capacity at maximum load. Oversized valves do not

have sufficient authority over the load in modulating

applications.

Oversized valves can cause excessive cycling and

the seat and ball can be damaged because of the

restricted opening.

Proper Use

These valves are only for use in cold, warm, and hot water

systems. Not suitable for oil, combustible gases, or steam.

They are designed for a medium temperature range of from 35

to 250°F, at a maximum pressure of 360 psig VBN valves are

to be operated with the appropriate Honeywell direct coupled

actuators only.

Water should be properly filtered, treated and conditioned

according to local conditions and the recommendations of the

boiler or chiller manufacturers. The installation of a strainers

and filters is recommended.

IMPORTANT

The presence of excessive iron oxide (red rust) in the

system voids the valve warranty.

Required Operating Torque

Both Honeywell non-spring return MVN and spring return low

torque direct coupled actuators can be utilized with the VBN2

and VBN3 valves. VB valves use a patented seat design that

reduces the torque needed from the actuator.

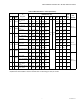

Table 7. Close-off, Differential Pressure Ratings.

TYPICAL SPECIFICATIONS

Valve Actuator

Direct coupled actuator shall accept analog modulating

[(0)2-10 Vdc], floating (tri-state), or two-position signal as

indicated in the control sequence. Actuators shall be by

Honeywell. Actuator shall provide minimum torque required

for full valve shutoff position. Wiring terminals shall be

provided for installation to control signal and power wiring.

Actuator shall be available with housing suitable for outdoor

installation.

Accessories Identification tags shall be available for all valves;

tags shall be indelibly marked with C

V

, model number, and tag

location.

Ball Valve

Valve housing shall consist of forged brass rated at no less

than 360 psi at 250°F. Standard valve ball shall consist of

chemically nickel-plated brass. Manufacturer shall be able to

provide optional 316 stainless steel ball and stem for 2-way

valves. Valve shall have a blow-out proof stem with two EPDM

O-rings with minimum 600 psi rating. Manufacturer shall be

able to provide glass-filled polymer ball insert to make flow

control equal percentage. Valves shall be Honeywell. The

2-way valves shall have EPDM O-rings behind ball seals to

allow for a minimum close-off pressure of 100 psi with

actuator which provides 35 lb-in. torque for 1/2 to 3 in. sizes.

Valve shall be available with a minimum of 53 unique C

V

values. Valve shall be available with threaded (FNPT) end

connections. The 3-way valves shall be installed in a “T”

configuration with actuator perpendicular to shaft. Valve shall

not require elbows of any kind. The 3-way valves shall have

EPDM O-rings behind ball seals to allow for a minimum close-

off pressure of 40 psi with an actuator that provides 35 lb-in.

torque for 1/2 to 2-1/2 in. sizes. The 3-way valves must be

available in both mixing and diverting configurations and shall

be available with a minimum of 42 unique C

V

values. Valve

shall be available with threaded (FNPT) end connections.

Valve

Type Valve Size (in.)

Close-off Pressure

Rating (psid)

2-way 1/2, 3/4 130

1, 1-1/4, 1-1/2, 2, 2-1/2, 3 100

3-way 1/2, 3/4, 1 50

1-1/4, 1-1/2, 2, 2-1/2 40

NOTE: 3-way close-off ratings apply to 3-way valves

with the B port plugged