5525B/31/32 Line Matrix Printer User's Manual

Table Of Contents

- 1 Introduction

- 2 Setting Up the Printer

- 3 Operating the Printer

- 4 The Configuration Menus

- Configuration Overview

- CONFIG. CONTROL

- ACTIVE EMULATION

- EMULATION

- PCL-II Emulation

- LinePrinter Plus Emulations

- Optional Emulations

- PCL-II Emulation

- LinePrinter Plus Emulation

- P-Series Emulation

- Proprinter XL Emulation

- Epson FX Emulation

- IGP/PGL Submenu

- Features

- Configuring the Emulation with the Control Panel

- Define CR Code (Carriage Return)

- Define LF Code (Line Feed)

- Autowrap

- Select SFCC

- PI Slew Range

- CR Edit

- Select Font

- Select LPI

- Auto Uppercase

- Skip Command Prefix

- Power On IGP/PGL

- Extended Execute Copy

- UPC Descenders

- Compressed CPI

- Ignore Character

- IGP100 Compatbl.

- Optimized Ratio

- IGP/VGL Emulation

- MAINT / MISC

- HOST INTERFACE

- ETHERNET PARAMETERS

- PRINTER CONTROL

- DIAGNOSTICS

- RIBBONMINDER

- 5 Interfaces

- Overview

- Dataproducts Long Line Interface

- IEEE 1284 Parallel Interface

- RS-232 and RS-422 Serial Interfaces

- Host System Configuration

- Internal Ethernet Adapter Configuration

- Configuring the Internal Ethernet Adapter for TCP/IP

- Host Software

- Compiling Host Software

- Computer-aided Configuration with ezsetup or npconfig

- Configuration Through the Network with ARP

- Configuration Through the Network with RARP

- Configuration Through the Network with BOOTP

- Restoring Factory Defaults

- Host Configuration

- Direct Printing Without Spooler

- Printing Via the Spooler

- Custom Interface Scripts

- BSD UNIX

- System V UNIX

- npd Pseudo-device Interface

- Other TCP/IP Methods

- Configuring The Internal Ethernet Adapter For Novell

- Configuring the Internal Ethernet Adapter for Windows

- 6 Troubleshooting

- A Printer Specifications

- B Downloading Firmware

- C ASCII Character Set

- D Communication and Trademark Information

Chapter 6 Diagnosing Problems

202

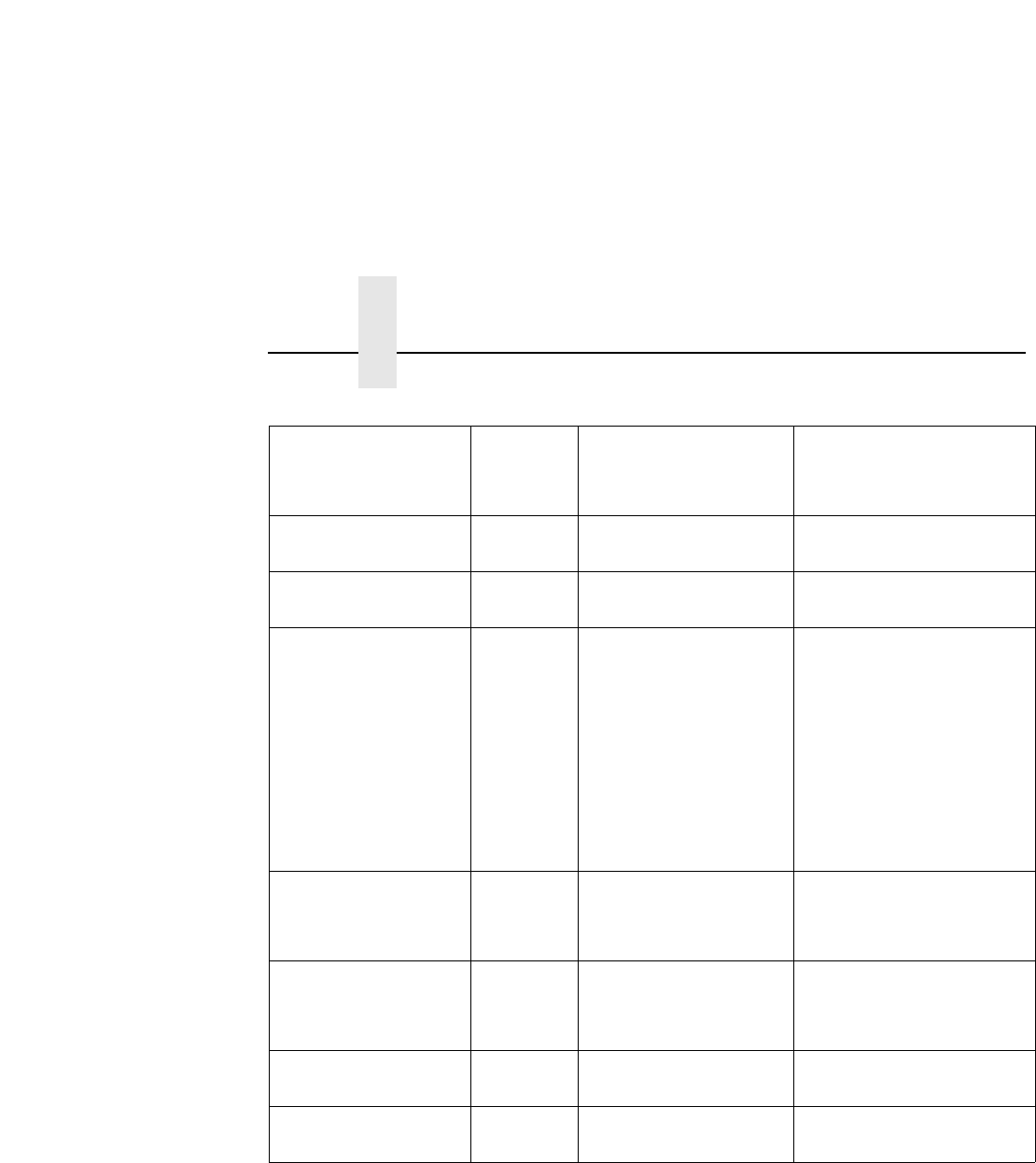

COIL HOT Yes One or more hammer coils

are hot.

Check printer environment. If too

hot or dusty, relocate printer. May

occur normally on graphically

intense print jobs.

CTL VOLT FAIL* No Controller voltage failure. Contact your authorized service

representative.

1

DRVR CIR BAD* No Hammer coil count test

failed.

Contact your authorized service

representative.

1

EXHAUST FAN FLT

(Cabinet model only)

Yes Sensors cannot detect

current in fan circuit.

Power off the printer and remove

the paper path (see

Maintenance

Manual).

Check that the fan

cable connector is connected.

Check for obstruction of vents

and fan airway, and remove any

obstructions. Check for items

beneath the printer blocking

cabinet vents. Power back on the

printer. If this message recurs,

contact your authorized service

representative.

1

FIRMWARE ERROR* No Application software tried to

perform an illegal printer

function or damaged

memory detected on board.

Contact your authorized service

representative.

1

FRAMING ERROR Yes Serial framing error (serial

interface).

Check your serial host interface

parameter settings; if necessary,

adjust them so that they match

the settings of the attached host.

HAM. COIL OPEN* No Electrical malfunction of one

or more hammer coils.

Contact your authorized service

representative.

1

HAMMER COIL BAD*

#, #, #

No Hammer coil # failed current

test at power up.

Contact your authorized service

representative.

1

Table 15. LCD Message Troubleshooting Table (continued)