5525B/31/32 Line Matrix Printer User's Manual

Table Of Contents

- 1 Introduction

- 2 Setting Up the Printer

- 3 Operating the Printer

- 4 The Configuration Menus

- Configuration Overview

- CONFIG. CONTROL

- ACTIVE EMULATION

- EMULATION

- PCL-II Emulation

- LinePrinter Plus Emulations

- Optional Emulations

- PCL-II Emulation

- LinePrinter Plus Emulation

- P-Series Emulation

- Proprinter XL Emulation

- Epson FX Emulation

- IGP/PGL Submenu

- Features

- Configuring the Emulation with the Control Panel

- Define CR Code (Carriage Return)

- Define LF Code (Line Feed)

- Autowrap

- Select SFCC

- PI Slew Range

- CR Edit

- Select Font

- Select LPI

- Auto Uppercase

- Skip Command Prefix

- Power On IGP/PGL

- Extended Execute Copy

- UPC Descenders

- Compressed CPI

- Ignore Character

- IGP100 Compatbl.

- Optimized Ratio

- IGP/VGL Emulation

- MAINT / MISC

- HOST INTERFACE

- ETHERNET PARAMETERS

- PRINTER CONTROL

- DIAGNOSTICS

- RIBBONMINDER

- 5 Interfaces

- Overview

- Dataproducts Long Line Interface

- IEEE 1284 Parallel Interface

- RS-232 and RS-422 Serial Interfaces

- Host System Configuration

- Internal Ethernet Adapter Configuration

- Configuring the Internal Ethernet Adapter for TCP/IP

- Host Software

- Compiling Host Software

- Computer-aided Configuration with ezsetup or npconfig

- Configuration Through the Network with ARP

- Configuration Through the Network with RARP

- Configuration Through the Network with BOOTP

- Restoring Factory Defaults

- Host Configuration

- Direct Printing Without Spooler

- Printing Via the Spooler

- Custom Interface Scripts

- BSD UNIX

- System V UNIX

- npd Pseudo-device Interface

- Other TCP/IP Methods

- Configuring The Internal Ethernet Adapter For Novell

- Configuring the Internal Ethernet Adapter for Windows

- 6 Troubleshooting

- A Printer Specifications

- B Downloading Firmware

- C ASCII Character Set

- D Communication and Trademark Information

21

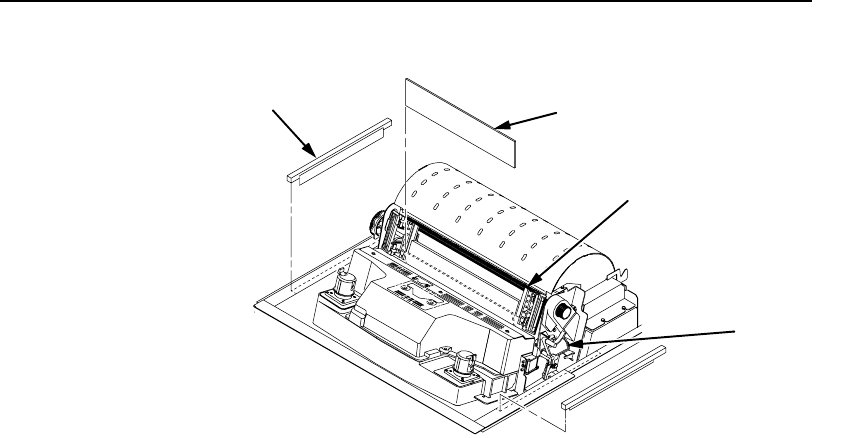

5. Slide the paper supports (4) outward as far as they will go. Lift the

hammer bank protective foam (5) and remove it from between the

ribbon mask and the platen.

6. Remove the foam strips (6) and the tape securing the foam strips.

7. Rotate the forms thickness lever (7) downward to position “A”.

6

5

4

7