H3C S7502 Ethernet Switch Installation Manual

Table Of Contents

- 00-1Cover.pdf

- 01-Chapter 1 Product Overview.pdf

- 02-Chapter 2 Line Processing Units.pdf

- 03-Chapter 3 nstallation Preparations.pdf

- 04-Chapter 4 Hardware Installation.pdf

- Chapter 4 Hardware Installation

- 05-Chapter 5 System Commissioning.pdf

- 06-Chapter 6 Hardware Maintenance.pdf

- 07-Chapter 7 Software Maintenance.pdf

- Chapter 7 Software Maintenance

- 7.1 Introduction to Loading Approaches

- 7.2 Loading Software Locally through Boot Menu

- 7.3 Loading Software Remotely or Locally through Command Lines

- 7.4 Booting the Switch with Dual Images

- 7.5 Loading a Host Software Containing the Boot ROM File

- 7.6 Handling Loading Failure

- 7.7 Handling Password Loss

- Chapter 7 Software Maintenance

- 08-Chapter 8 Troubleshooting.pdf

- 09-Appendix A Lightning Protection.pdf

- 10-Appendix B AC Power Cables Used in Different Countries.pdf

Installation Manual

H3C S7502 Ethernet Switch Chapter 4 Hardware Installation

4-15

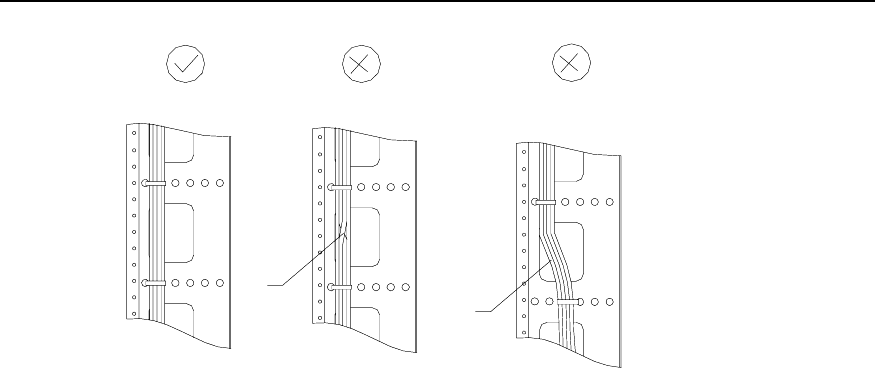

Twisting

Bending

Twisting

Bending

Figure 4-17 Cable binding example I

z The radius of the curve at which a cable is bent should be no less than twice of the

cable’s diameter. At the point where a cable runs out of a connector, the radius of

the curve at which the cable is bent should be no less than five times of its

diameter.

z Cables of different type (that is, power cable, signal cable, grounding cable, etc.)

should run and be bound separately in a cabinet. They cannot be bound together.

If they are close to each other, you can cable them in a crossing way. For parallel

cabling, the space between power cable and signal cable should be no less than

30mm;

z The cable binding rack and cable channel inside and outside a cabinet should be

smooth and stretch no sharp points.

z The metal hole through which a cable runs should have a smooth and fully surface

or an insulating bush;

z Use the right type of ties to bind the cables. Do not bind any cables with tied ties.

The following types of ties are provided: 100*2.5mm, 150*3.6mm, 300*3.6mm,

530*9mm, and 580*13mm;

z Bind the cables with ties and cut the extra parts. Trim the cut and leave no sharp

points. See the following figure: