Manual

Table Of Contents

- 1. Overview

- 2. Specifications and Name of Each Part

- 2.1 General Specifications

- 2.2 External Dimensions

- 2.3 Name and Function of Each Part

- [1] Gateway status indicator LEDs

- [2] SIO communication status LEDs

- [3] Mode setting switch

- [4] External port switching input

- [5] Controller communication lines

- [6] DeviceNet communication connector

- [7] Baud-rate setting switches

- [8] Node-address setting switches

- [9] DeviceNet communication status LEDs

- [10] Port switch

- [11] Teaching pendant/PC connector

- [12] Power-supply input

- 3. Installation and Noise Elimination Measures

- 4. Wiring

- 4.1 Overall Configuration

- 4.2 I/O Signals of Gateway Unit

- 4.3 Design of SIO Communication Network (SIO Communication)

- 4.3.1 Wiring

- (1) Basics

- (2) Linking PCON/ACON/SCON controllers via SIO communication

- (3) Linking ERC2-SE controllers via SIO communication

- (4) Linking ERC2-NP/PN controllers via SIO communication

- (5) Wiring the emergency stop (EMG) circuit

- [1] Example of cutting off drive signals

- [2] Example of cutting off motor drive power

- 4.3.2 Axis Number Setting

- 4.3.1 Wiring

- 4.4 How to Connect Teaching Tools When Grounding the Positive Terminal of the 24-V Power Supply

- 5. Overview of DeviceNet

- 6. Address Configuration of Gateway Unit

- 7. Communication Signal Details

- 7.1 Overview of Communication Signal Timings

- 7.2 Communication Signals and Operation Timings

- (1) Controller ready (PWR)

- (2) Emergency stop (EMGS)

- (3) Alarm (ALM)

- (4) Reset (RES)

- (5) Pause (STP)

- (6) Moving (MOVE)

- (7) Servo ON command (SON)

- (8) Home return command (HOME)

- (9) Positioning start (CSTR)

- (10) Position complete (PEND)

- (11) Command position number (PC1 to PC512)

- (12) Completed position number (PM1 to PM256)

- (13) Zone (PZONE, ZONE1, ZONE2)

- (14) Jog + command/jog- command (JOG+/JOG-)

- (15) Jog/inching switching (JISL)

- (16) Teaching mode command (MOD)

- (17) Position data read command (PWRT)

- (18) Forced brake release (BKRL)

- 7.3 Basic Operation Timings

- 7.4 Command Transmission

- 8. Network System Building Procedure

- 8.1 Procedure

- 8.2 Settings for Controller Communication

- 8.3 Setting the Gateway Unit and PLC Master

- 8.4 Assigning the Master PLC Address by Free Assignment

- 8.5 Assigning the Master PLC Address by Fixed Assignment

- 9. Example of DeviceNet Operation

- 10. Troubleshooting

109

DeviceNet Gateway

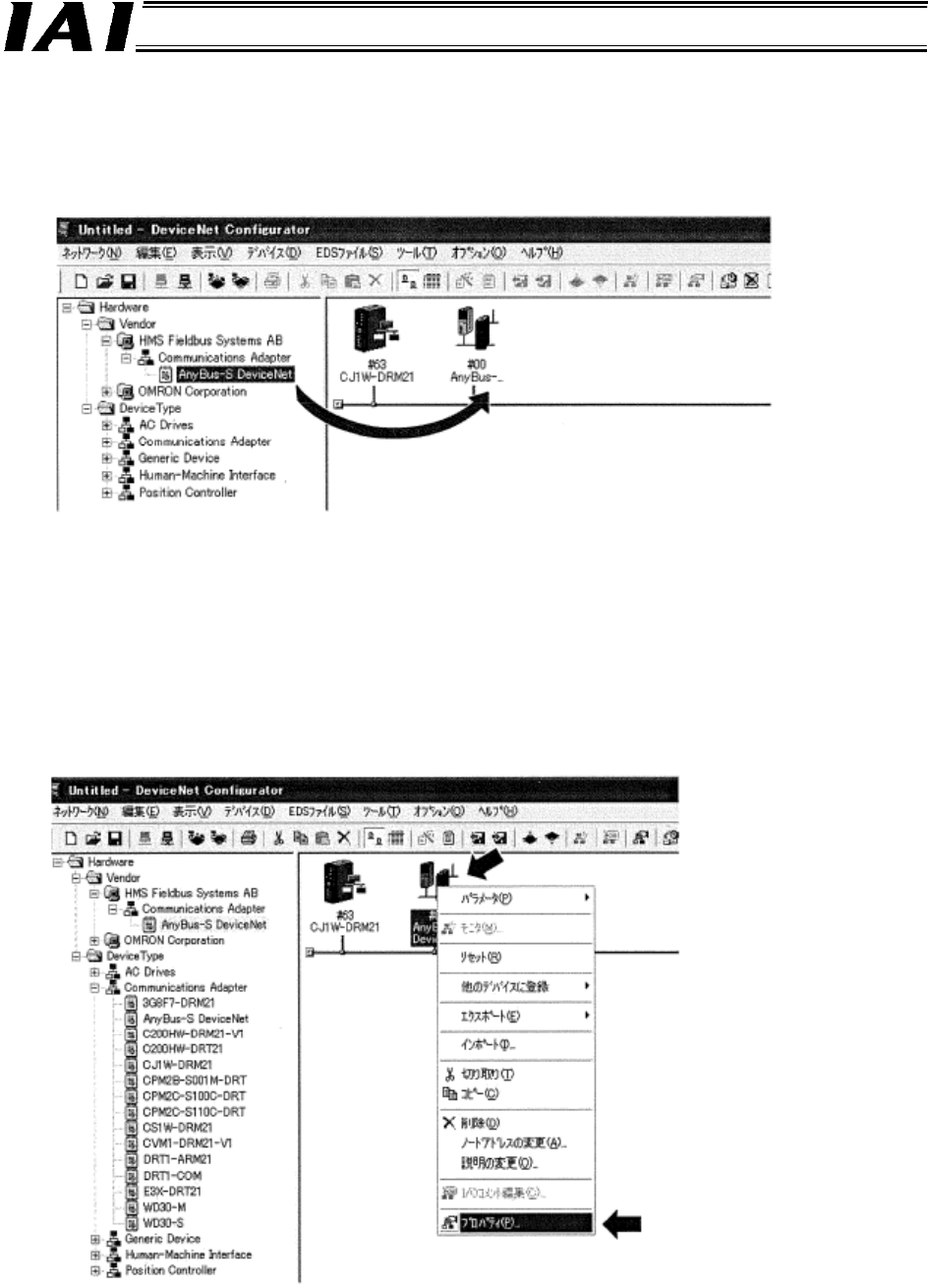

(3) Registering the slave

In the hardware list, select the EDS file list you have registered in (1), and then drag and drop the file

to add it the network configuration pane.

The slave is automatically assigned a node address in the order in which it is registered in the

network configuration pane.

8.4.3 Creating a Scan List

A scan list is where the slaves that communicate with the master via remote I/O communication over the

DeviceNet network are registered. Use the configurator to assign I/Os for the slave station and register the

assignments to the master.

(1) Setting the I/O size for the slave station (Assigning I/Os for the Gateway Unit)

[1] Select and right-click the slave station (node) added in step (3) of 8.4.2, and then left-click

Properties (P).