Manual

Table Of Contents

- 1. Overview

- 2. Specifications and Name of Each Part

- 2.1 General Specifications

- 2.2 External Dimensions

- 2.3 Name and Function of Each Part

- [1] Gateway status indicator LEDs

- [2] SIO communication status LEDs

- [3] Mode setting switch

- [4] External port switching input

- [5] Controller communication lines

- [6] DeviceNet communication connector

- [7] Baud-rate setting switches

- [8] Node-address setting switches

- [9] DeviceNet communication status LEDs

- [10] Port switch

- [11] Teaching pendant/PC connector

- [12] Power-supply input

- 3. Installation and Noise Elimination Measures

- 4. Wiring

- 4.1 Overall Configuration

- 4.2 I/O Signals of Gateway Unit

- 4.3 Design of SIO Communication Network (SIO Communication)

- 4.3.1 Wiring

- (1) Basics

- (2) Linking PCON/ACON/SCON controllers via SIO communication

- (3) Linking ERC2-SE controllers via SIO communication

- (4) Linking ERC2-NP/PN controllers via SIO communication

- (5) Wiring the emergency stop (EMG) circuit

- [1] Example of cutting off drive signals

- [2] Example of cutting off motor drive power

- 4.3.2 Axis Number Setting

- 4.3.1 Wiring

- 4.4 How to Connect Teaching Tools When Grounding the Positive Terminal of the 24-V Power Supply

- 5. Overview of DeviceNet

- 6. Address Configuration of Gateway Unit

- 7. Communication Signal Details

- 7.1 Overview of Communication Signal Timings

- 7.2 Communication Signals and Operation Timings

- (1) Controller ready (PWR)

- (2) Emergency stop (EMGS)

- (3) Alarm (ALM)

- (4) Reset (RES)

- (5) Pause (STP)

- (6) Moving (MOVE)

- (7) Servo ON command (SON)

- (8) Home return command (HOME)

- (9) Positioning start (CSTR)

- (10) Position complete (PEND)

- (11) Command position number (PC1 to PC512)

- (12) Completed position number (PM1 to PM256)

- (13) Zone (PZONE, ZONE1, ZONE2)

- (14) Jog + command/jog- command (JOG+/JOG-)

- (15) Jog/inching switching (JISL)

- (16) Teaching mode command (MOD)

- (17) Position data read command (PWRT)

- (18) Forced brake release (BKRL)

- 7.3 Basic Operation Timings

- 7.4 Command Transmission

- 8. Network System Building Procedure

- 8.1 Procedure

- 8.2 Settings for Controller Communication

- 8.3 Setting the Gateway Unit and PLC Master

- 8.4 Assigning the Master PLC Address by Free Assignment

- 8.5 Assigning the Master PLC Address by Fixed Assignment

- 9. Example of DeviceNet Operation

- 10. Troubleshooting

DeviceNet Gateway

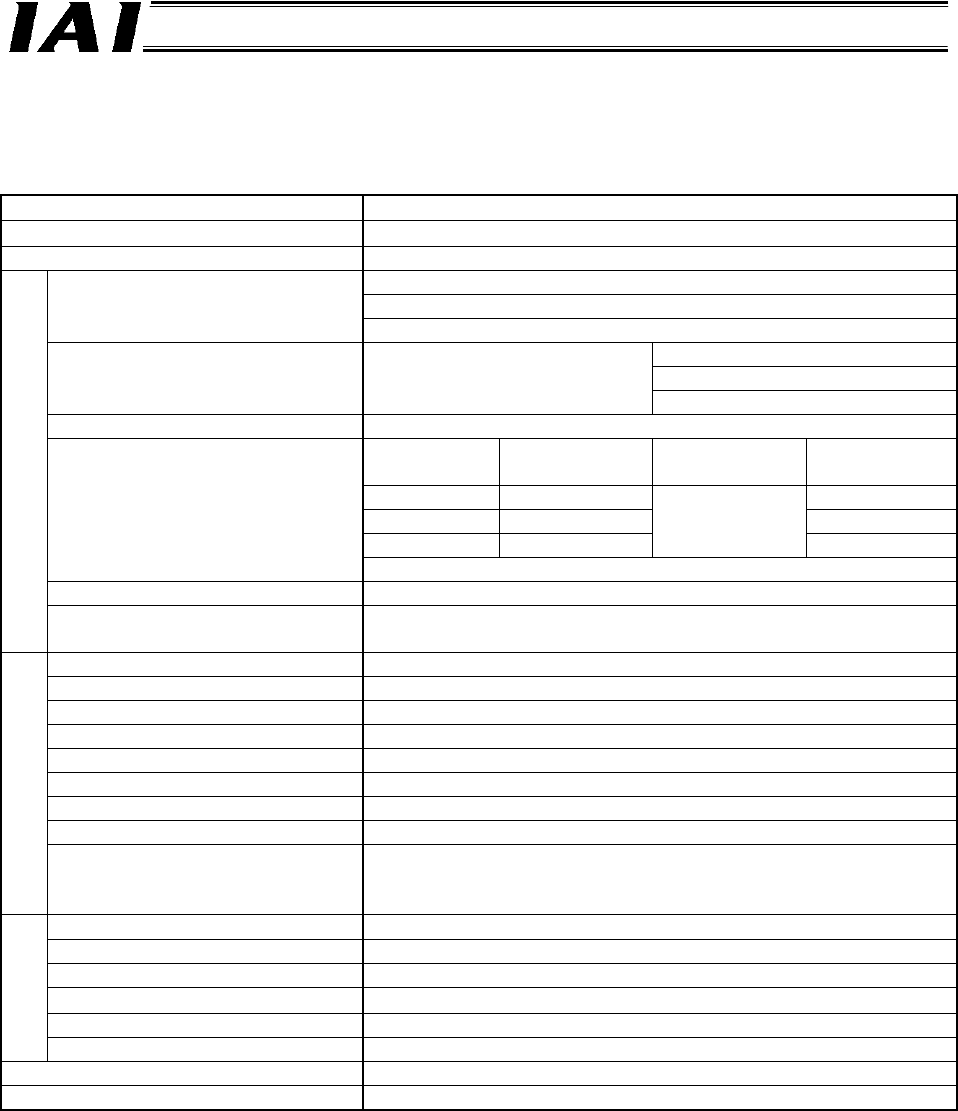

2. Specifications and Name of Each Part

2.1 General Specifications

Item Specification

Power supply

24 VDC ± 10%

Current consumption 300 mA max.

A certified DeviceNet 2.0 interface module is used.

Group 2 only server

Communication standard

Insulated node of network powered operation type

Bit strobe

Polling

Communication specification Master-slave connection

Cyclic

Baud rate 500 k / 250 k / 125 kbps (Changed by DIP switches)

Baud rate

Maximum

network length

Maximum

branch length

Total branch

length

500 kbps 100 m 39 m

250 kbps 250 m 78 m

125 kbps 500 m

6 m

156 m

Communication cable length (*1)

Note) When a thick DeviceNet cable is used.

Occupied nodes 1 node

DeviceNet specifications

Communication power supply Voltage: 24 VDC (supplied from DeviceNet)

Current consumption: 60 mA

Transmission path configuration IAI’s original multi-drop differential communication

Communication method Half-duplex

Synchronization method Asynchronous

Transmission path type EIA RS485, 2-wire type

Baud rate 230.4 kbps

Error control method No parity bit, CRC (*2)

Communication cable length Total cable length: 100 m max.

Connected units 16 axes max.

SIO communication

specifications

Communication cable

Double shielded twisted-pair cable

(Recommended cable:

HK-SB/20276 X L, 2P X AWG22 by Taiyo Electric Wire & Cable)

Surrounding air temperature

0 to 40° C

Surrounding humidity 85% RH or below (non-condensing)

Surrounding environment Free from corrosive or flammable gases, oil mist or powder dust

Storage temperature

-10 to 65° C

Storage humidity 90% RH or below (non-condensing)

Environment

Vibration durability 4.9 m/s

2

(0.5 G)

Protection class IP20

Weight 480 g or below

*1 Refer to the operation manuals for your master unit and PLC in the case of T-branch communication.

*2 CRC: Cyclic Redundancy Check

A data error detection method commonly used in synchronous transmission.