Manual

Table Of Contents

- 1. Overview

- 2. Specifications and Name of Each Part

- 2.1 General Specifications

- 2.2 External Dimensions

- 2.3 Name and Function of Each Part

- [1] Gateway status indicator LEDs

- [2] SIO communication status LEDs

- [3] Mode setting switch

- [4] External port switching input

- [5] Controller communication lines

- [6] DeviceNet communication connector

- [7] Baud-rate setting switches

- [8] Node-address setting switches

- [9] DeviceNet communication status LEDs

- [10] Port switch

- [11] Teaching pendant/PC connector

- [12] Power-supply input

- 3. Installation and Noise Elimination Measures

- 4. Wiring

- 4.1 Overall Configuration

- 4.2 I/O Signals of Gateway Unit

- 4.3 Design of SIO Communication Network (SIO Communication)

- 4.3.1 Wiring

- (1) Basics

- (2) Linking PCON/ACON/SCON controllers via SIO communication

- (3) Linking ERC2-SE controllers via SIO communication

- (4) Linking ERC2-NP/PN controllers via SIO communication

- (5) Wiring the emergency stop (EMG) circuit

- [1] Example of cutting off drive signals

- [2] Example of cutting off motor drive power

- 4.3.2 Axis Number Setting

- 4.3.1 Wiring

- 4.4 How to Connect Teaching Tools When Grounding the Positive Terminal of the 24-V Power Supply

- 5. Overview of DeviceNet

- 6. Address Configuration of Gateway Unit

- 7. Communication Signal Details

- 7.1 Overview of Communication Signal Timings

- 7.2 Communication Signals and Operation Timings

- (1) Controller ready (PWR)

- (2) Emergency stop (EMGS)

- (3) Alarm (ALM)

- (4) Reset (RES)

- (5) Pause (STP)

- (6) Moving (MOVE)

- (7) Servo ON command (SON)

- (8) Home return command (HOME)

- (9) Positioning start (CSTR)

- (10) Position complete (PEND)

- (11) Command position number (PC1 to PC512)

- (12) Completed position number (PM1 to PM256)

- (13) Zone (PZONE, ZONE1, ZONE2)

- (14) Jog + command/jog- command (JOG+/JOG-)

- (15) Jog/inching switching (JISL)

- (16) Teaching mode command (MOD)

- (17) Position data read command (PWRT)

- (18) Forced brake release (BKRL)

- 7.3 Basic Operation Timings

- 7.4 Command Transmission

- 8. Network System Building Procedure

- 8.1 Procedure

- 8.2 Settings for Controller Communication

- 8.3 Setting the Gateway Unit and PLC Master

- 8.4 Assigning the Master PLC Address by Free Assignment

- 8.5 Assigning the Master PLC Address by Fixed Assignment

- 9. Example of DeviceNet Operation

- 10. Troubleshooting

71

DeviceNet Gateway

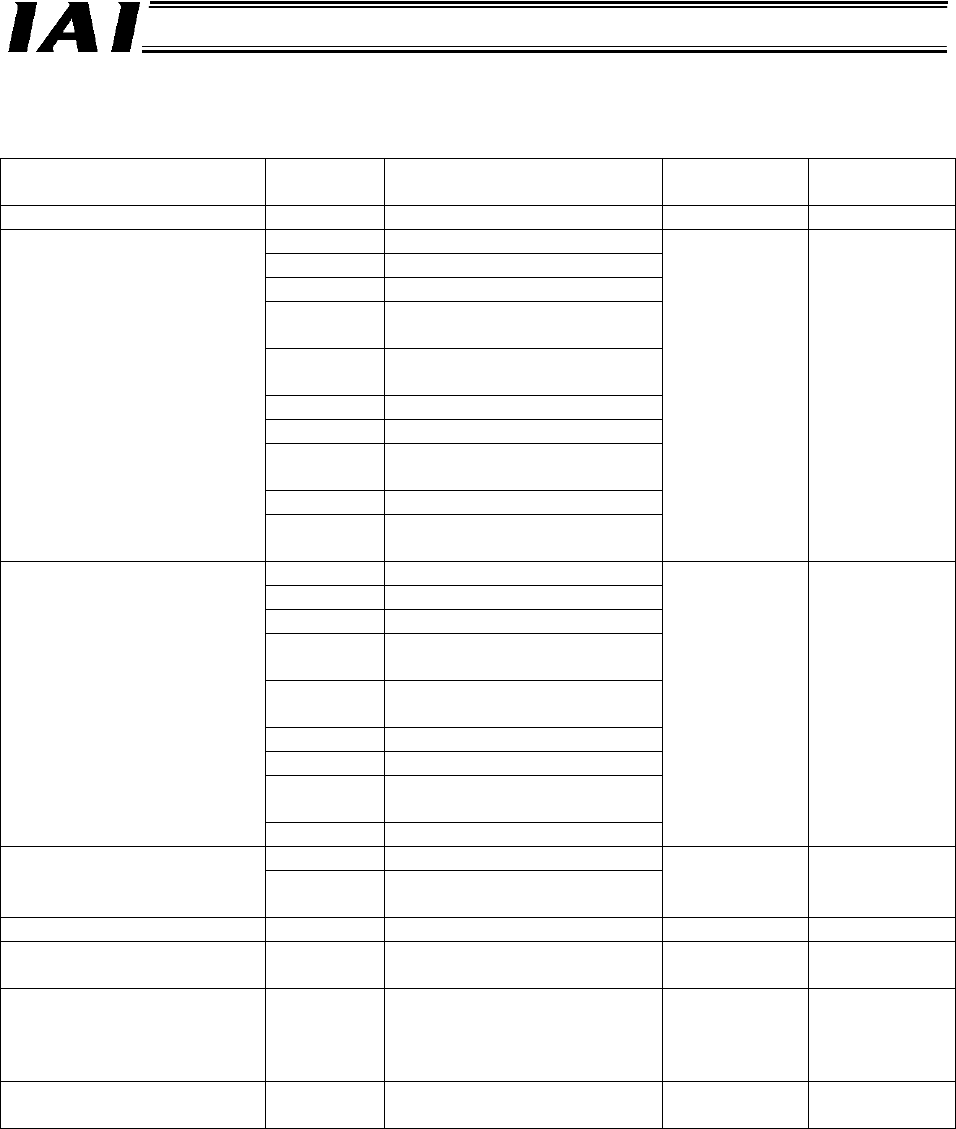

(2) Command list

The available commands and corresponding command codes are listed below.

Function category Code Description

Positioner

operation axis

Simple direct

operation axis

Handshake 0000H Clear a request command

{ {

1000H Write a target position

1001H Write a positioning band

1002H Write a speed

1003H

Write an individual zone

boundary +

1004H

Write an individual zone

boundary –

1005H Write an acceleration

1006H Write a deceleration

1007H

Write a current-limiting value

for push-motion operation

1008H Write a load current threshold

Position table data write

1009H

Write a push-motion

operation setting

{

X

1040H Read a target position

1041H Read a positioning band

1042H Read a speed

1043H

Read an individual zone

boundary +

1044H

Read an individual zone

boundary –

1045H Read an acceleration

1046H Read a deceleration

1047H

Read a current-limiting value

for push-motion operation

Position table data read

1048H Read a load current threshold

{

X

0DA0H Write a POS write coil Position table data write

(ROM)

02E0H

Read a POS write completion

coil

{

X

Present alarm code read 0342H Read a present alarm code

{ {

Current position read

0440H

Read the current position of a

specified axis

{ {

Group-specified broadcast

0D03H

Synchronously move multiple

axes to the position

corresponding to the same

POS number

{

X

PIO/Modbus control

switching

0DA1H

Switch between PIO and

Modbus modes.

X

{

: Available, X: Not available