Manual

Table Of Contents

- 1. Overview

- 2. Specifications and Name of Each Part

- 2.1 General Specifications

- 2.2 External Dimensions

- 2.3 Name and Function of Each Part

- [1] Gateway status indicator LEDs

- [2] SIO communication status LEDs

- [3] Mode setting switch

- [4] External port switching input

- [5] Controller communication lines

- [6] DeviceNet communication connector

- [7] Baud-rate setting switches

- [8] Node-address setting switches

- [9] DeviceNet communication status LEDs

- [10] Port switch

- [11] Teaching pendant/PC connector

- [12] Power-supply input

- 3. Installation and Noise Elimination Measures

- 4. Wiring

- 4.1 Overall Configuration

- 4.2 I/O Signals of Gateway Unit

- 4.3 Design of SIO Communication Network (SIO Communication)

- 4.3.1 Wiring

- (1) Basics

- (2) Linking PCON/ACON/SCON controllers via SIO communication

- (3) Linking ERC2-SE controllers via SIO communication

- (4) Linking ERC2-NP/PN controllers via SIO communication

- (5) Wiring the emergency stop (EMG) circuit

- [1] Example of cutting off drive signals

- [2] Example of cutting off motor drive power

- 4.3.2 Axis Number Setting

- 4.3.1 Wiring

- 4.4 How to Connect Teaching Tools When Grounding the Positive Terminal of the 24-V Power Supply

- 5. Overview of DeviceNet

- 6. Address Configuration of Gateway Unit

- 7. Communication Signal Details

- 7.1 Overview of Communication Signal Timings

- 7.2 Communication Signals and Operation Timings

- (1) Controller ready (PWR)

- (2) Emergency stop (EMGS)

- (3) Alarm (ALM)

- (4) Reset (RES)

- (5) Pause (STP)

- (6) Moving (MOVE)

- (7) Servo ON command (SON)

- (8) Home return command (HOME)

- (9) Positioning start (CSTR)

- (10) Position complete (PEND)

- (11) Command position number (PC1 to PC512)

- (12) Completed position number (PM1 to PM256)

- (13) Zone (PZONE, ZONE1, ZONE2)

- (14) Jog + command/jog- command (JOG+/JOG-)

- (15) Jog/inching switching (JISL)

- (16) Teaching mode command (MOD)

- (17) Position data read command (PWRT)

- (18) Forced brake release (BKRL)

- 7.3 Basic Operation Timings

- 7.4 Command Transmission

- 8. Network System Building Procedure

- 8.1 Procedure

- 8.2 Settings for Controller Communication

- 8.3 Setting the Gateway Unit and PLC Master

- 8.4 Assigning the Master PLC Address by Free Assignment

- 8.5 Assigning the Master PLC Address by Fixed Assignment

- 9. Example of DeviceNet Operation

- 10. Troubleshooting

73

DeviceNet Gateway

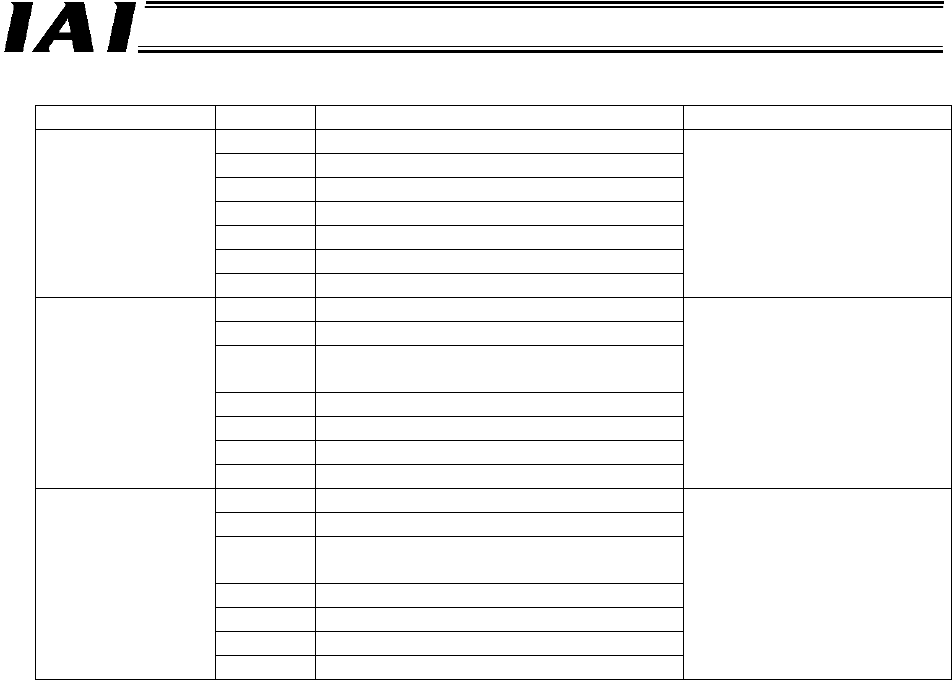

Command name CH+ PLC output (request) PLC input (response)

+2 1006H

3 Position number

4 Deceleration data *4

5 0

6 Axis number 0 to FH *2

7 (RSV)

Write a

deceleration

8 (RSV)

Same as the requested

value, if the command was

successful.

+2 1007H

3 Position number

4

0000 ~ 00FFH (00FH: Maximum

current)

5 0

6 Axis number 0 to FH *2

7 (RSV)

Write a current-

limiting value for

push-motion

operation *5

8 (RSV)

Same as the requested

value, if the command was

successful.

+2 1008H

3 Position number

4

0000 ~ 00FFH (00FH: Maximum

current)

5 0

6 Axis number 0 to FH *2

7 (RSV)

Write a load

current threshold

8 (RSV)

Same as the requested

value, if the command was

successful.

*1) Signed 32-bit integer data

*2) Axis numbers 0 to 15 correspond to data 00 to 0FH, respectively.

*3) 32-bit integer data

*4) Eight-bit integer data

*5) Valid only with position table numbers under which a push-current limiting value other than zero

is set (= push-motion operation is set).