Manual

Table Of Contents

- 1. Overview

- 2. Specifications and Name of Each Part

- 2.1 General Specifications

- 2.2 External Dimensions

- 2.3 Name and Function of Each Part

- [1] Gateway status indicator LEDs

- [2] SIO communication status LEDs

- [3] Mode setting switch

- [4] External port switching input

- [5] Controller communication lines

- [6] DeviceNet communication connector

- [7] Baud-rate setting switches

- [8] Node-address setting switches

- [9] DeviceNet communication status LEDs

- [10] Port switch

- [11] Teaching pendant/PC connector

- [12] Power-supply input

- 3. Installation and Noise Elimination Measures

- 4. Wiring

- 4.1 Overall Configuration

- 4.2 I/O Signals of Gateway Unit

- 4.3 Design of SIO Communication Network (SIO Communication)

- 4.3.1 Wiring

- (1) Basics

- (2) Linking PCON/ACON/SCON controllers via SIO communication

- (3) Linking ERC2-SE controllers via SIO communication

- (4) Linking ERC2-NP/PN controllers via SIO communication

- (5) Wiring the emergency stop (EMG) circuit

- [1] Example of cutting off drive signals

- [2] Example of cutting off motor drive power

- 4.3.2 Axis Number Setting

- 4.3.1 Wiring

- 4.4 How to Connect Teaching Tools When Grounding the Positive Terminal of the 24-V Power Supply

- 5. Overview of DeviceNet

- 6. Address Configuration of Gateway Unit

- 7. Communication Signal Details

- 7.1 Overview of Communication Signal Timings

- 7.2 Communication Signals and Operation Timings

- (1) Controller ready (PWR)

- (2) Emergency stop (EMGS)

- (3) Alarm (ALM)

- (4) Reset (RES)

- (5) Pause (STP)

- (6) Moving (MOVE)

- (7) Servo ON command (SON)

- (8) Home return command (HOME)

- (9) Positioning start (CSTR)

- (10) Position complete (PEND)

- (11) Command position number (PC1 to PC512)

- (12) Completed position number (PM1 to PM256)

- (13) Zone (PZONE, ZONE1, ZONE2)

- (14) Jog + command/jog- command (JOG+/JOG-)

- (15) Jog/inching switching (JISL)

- (16) Teaching mode command (MOD)

- (17) Position data read command (PWRT)

- (18) Forced brake release (BKRL)

- 7.3 Basic Operation Timings

- 7.4 Command Transmission

- 8. Network System Building Procedure

- 8.1 Procedure

- 8.2 Settings for Controller Communication

- 8.3 Setting the Gateway Unit and PLC Master

- 8.4 Assigning the Master PLC Address by Free Assignment

- 8.5 Assigning the Master PLC Address by Fixed Assignment

- 9. Example of DeviceNet Operation

- 10. Troubleshooting

78

DeviceNet Gateway

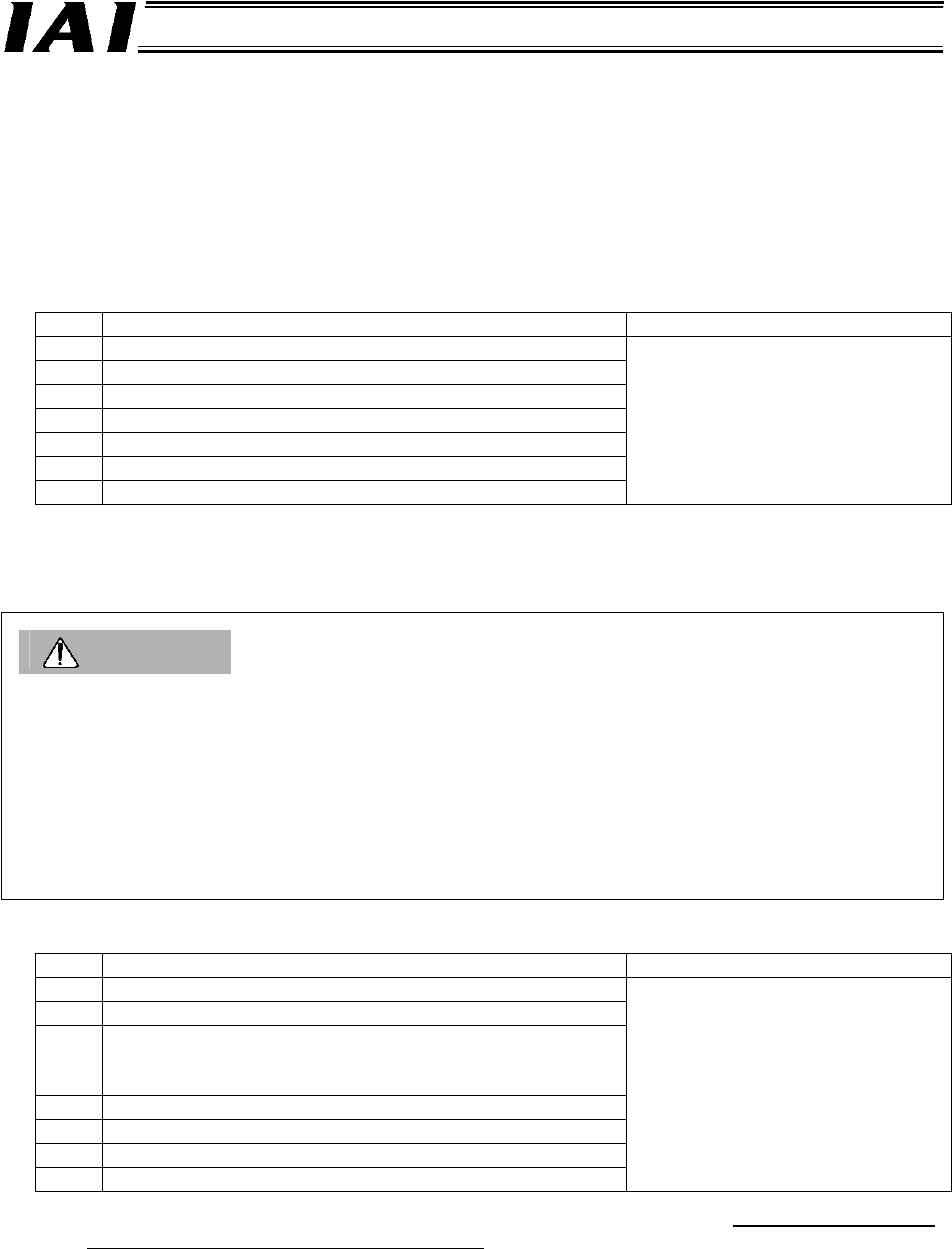

[6] “Group-specified broadcast” command

The axes specified by a group number are started simultaneously toward the position specified by a

POS number.

This command causes the Gateway to communicate with each ROBO Cylinder controller in the

broadcast mode, and accordingly the ROBO Cylinder controller does not return any response.

The response result indicated by a PLC input only means that the command has been sent

successfully to the ROBO Cylinder controller; it does not indicate the status of the ROBO Cylinder

controller. Check the status of each ROBO Cylinder controller using the status signal for the

applicable axis.

CH+ PLC output (request) PLC input (response)

+2 0D03H

3 Target POS number *1

4 Group ID number *2

5 0

6 0

7 (RSV)

8 (RSV)

Same as the requested value, if

the command was successful.

*1) The values that can be specified vary depending on the type and settings of each ROBO

Cylinder controller.

*2) If this number is “0,” all linked axes will move regardless of the group specification. Set the group

number using the applicable system parameter in the PC software.

Caution

1. If a different movement command is issued using a control signal for each axis while the axis is still

moving as a result of the group-specified broadcast operation command, the movement by the

group-specified broadcast operation command will be cancelled and the axis will operate according

to the latest movement command. This means that each axis effectively has two movement

command interfaces. Accordingly, make sure only one of the two interfaces is used at a given time.

2. Even if the link is cancelled by turning OFF the CFG bit of the gateway control signal, the controller

will always receive and execute the group-specified broadcast operation command once a link is

established thereafter.

[7] “PIO/Modbus switching” command

CH+ PLC output (request) PLC input (response)

+2 0DA1H

3 0

4

Coil ON/OFF

00FFH = ON: Modbus (Disable PIO commands)

0000H = OFF: PIO (Enable PIO commands) *1 to *3

5 0

6 Axis number 0 to FH

7 0

8 0

Same as the requested value, if

the command was successful.

*1) The PIO/Modbus switching status is reflected in the status signal PMSS. This command cannot

be set for position-number specification axes (an invalid request error (0103H) will generate).

*2) Even if the coil is turned OFF (PIO commands are enabled), it is still possible to change the

position data for a given axis via Modbus communication from the PLC (the link must be

maintained).

*3) The controller receives and executes movement commands received via Modbus

communication, even in the PIO control mode.