Power Screwdriver User Manual

636103PAGE2OF4

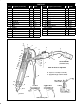

Direction of lubricant flow.

Filter (disc type or screen type)

A

B

C

17

SECTION 1

If little or no lubricant can be obtained from the control handle:

A. Check air line connection to pump to make certain there is air presĆ

sure to the pump.

B. Check lubricant container to make certain lubricant is not exĆ

hausted.

C. If above conditions are okay and no lubricant can be obtained from the

control handle, clean the filter in the bottom of the control handle.

1. Disconnect or shut off the air supply to the pump.

2. Pull (14) handle on the control handle to relieve pressure in the line

from pump to the control handle.

3. Remove control handle from swivel slowly. If filter is plugged, there

can still be some pressure retained in the line. Remove the control

handle slowly to allow pressure to bleed off slowly so that no injury

can be caused by grease injection.

4. Remove (16) adapter from control handle.

5. Remove (18) spring and (17) filter.

a. Clean exterior of filter in a solvent with a brush to remove most of

the foreign material and lubricant from the outside of the filter.

b. Blow air through the filter in the oposite direction of lubricant flow.

CAUTION: Be sure to wear eye protection, goggles or glasses

when doing this.

c. Repeat directions a" and b" until filter is clean.

6. If filter is damaged, replace it. (Deformed discs on old style filter or

broken screen on new style filter which would allow dirt to pass on

thru the filter).

7. Reassemble control handle and then assemble to swivel.

SECTION 2

If lubricant leaks excessively around top of (5) piston:

A. Replace the two (26) packings. Also replace (5) piston if it is badly

scored on area that packing seals.

1. Follow instruction 1,2 and 3 as described in Section 1.

2. Remove the (1) nut and (2) pin that holds the two (28) links to the

(27) head. This will allow the (14) handle to be moved out of the way

from the (5) piston.

3. Place the flats of the (15) body in a vice.

4. Use an end wrench or crescent wrench on the flats of the (27) head

and remove the head from the (15) body.

5. Remove (25) spring and (23) spring from the (27) head.

6. Remove the (5) piston by pulling it out of the top of the (27) head.

7. Remove the (25) washer and two (26) packings from the (27) head.

8. Install two new (26) packings and (25) washer in the (27) head.

9. Reassemble the control handle in the reverse sequence of disasĆ

sembly steps 6, 5, 4.

SECTION 3

If control handle will not develop additional pressure:

A. If dirt got by the (17) filter in the bottom of the control handle, the (9)

outlet check may be fouled or the (19) balls in the (15) body may be

fouled.

1. Follow instruction 1,2 and 3 as described in Section 1.

2. Remove (8) valve body from (10) body.

3. Remove (11) retainer, (12) spring and (13) ball.

4. Clean ball seat of (10) body and (13) ball.

5. Examine ball seat of (10) body and (13) ball for nicks or score

marks. Replace damaged parts.

6. Remove (27) head from (15) body.

7. Remove (22) valve seat, two (19) balls, two (20) ball stops and (21)

spring from (15) body.

8. Clean ball seat in (15) body, ball seat in (22) valve seat and two (19)

balls.

9. Examine ball seats and balls for nicks or score marks. Replace

damaged parts.

10. Reassemble in the reverse sequence steps 8,7,6,5,3,2. See drawĆ

ing of control handle for correct placement of parts.

SECTION 4

If 636028 Hydraulic Coupler locks onto the grease fitting and cannot be

removed:

A. Unscrew the (6) needle one to two turns. This will relieve the grease

pressure out of the bleed hole beside the (6) needle.

B. Remove control handle from the grease fitting and retighten the (6)

needle.