User Guide

6.13 Field parameter "EP1 - EP8"

7. Wiring instruction

After setting the instrument, most parameters don’t need to be amended

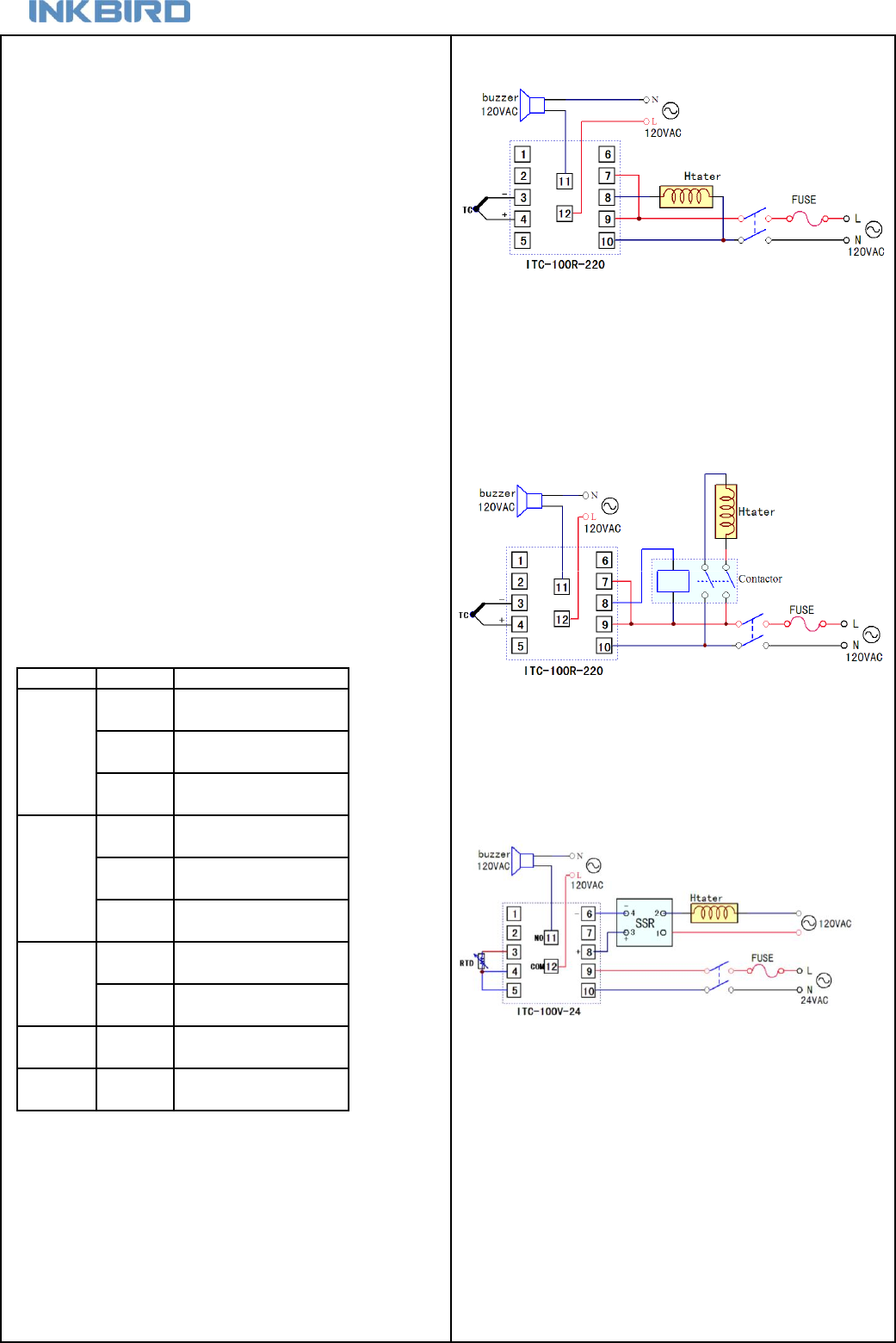

7.1 Directly control load by the internal relay of the instrument.

at field. Besides, operators generally don’t understand many parameters,

and there is risk of fault caused by wrong setting by operators.

Generally, intelligent instrument has parameter lock (Loc) function. Common

parameter lock will lock all the parameters. Sometimes, certain parameters

need to be amended or adjusted at field by the operators. For example,

parameters such as alarm high limit or alarm low limit. In parameter table,

EP1 - EP 8 are 8 field parameters for operators. The value of parameter

EP is other parameters, such as HiAL and LoAL. When Loc=0 or 1,

selected parameters will be displayed, other parameters won’t be displayed

and amended. This function can speed up the amendment, and avoid

important parameters (such as input and output parameters) been

amended incorrectly. Control the heater by the internal relay of the instrument, no external control

There are maximum 8 field parameters available for parameter EP1- EP2. circuit is needed. This mode is only applicable for heater whose maximum

If field parameters are less than 8 (sometime none), they should be defined load is 250V/3A or 120V/6A.

orderly from EP1 to EP8. Vacant field parameters are defined as nonE. The internal control of alarm is relay output control which controls the power

supply of the speaker. User can use bulb to replace with the speaker as alarm.

6.14 Permission for parameters “Loc”

Protection function Loc: when Loc is set as value except 2, 40, 808, the

7.2 Control the load via external contactor

instrument only display the filed parameters (EP1 - EP8) and Loc. Only if

set Loc as 2, 40 or 808, all the parameters can be amended.

When Loc=0, field parameters (EP1 - EP8)and temperature setting

value can be amended.

When Loc=1, field parameters can’t be amended (except Loc).

When Loc=2, 40 or 808, all the parameters and temperature setting

value can be amended.

6.15 Common faults and handling methods

Table 5:Error and handling

Instrument control output via external relay or contactor. With this method,

the user can select external relay or contactor based on the power of heater,

avoid output limitation of the internal relay of the instrument, and improve the

lifetime of the instrument.

7.3 SSR control

ITC-100VH’s output control signal is DC12V voltage for controlling external

SSR to control the heater. User can select SSR based on the power of the

heater. SSR is a kind of electronic switch without contactor, which can be

used for higher frequency control than relay, featuring more stable temperature

control for heater and long lifetime.

orAL displayed

on the

instrument

Sensor fault

Check whether sensor is connected

correctly

Malfunction of

relay

Wrong setting

for control

output

Figure 8:ITC-100RH Wiring diagram

Figure 10:ITC-100VH Wiring diagram

Faults

Figure 9:ITC-100RH Wiring diagram

Power cable is

not well

connected

Check whether the power cable is

bad or wrongly connected

Instrument fault

Contact manufacturer or dealer

Wrong

measured value

Wrong

graduation

mark selected

Select correct graduation mark in

accordance with input signal

Wrong

connection for

sensors

Connect signal cable correctly

Reasons

Handling methods

PV and SV

screen not work

Wrong input

voltage

Check whether the input voltage is in

accordance with the specification of

the instrument

Refer to the alarm instruction in the

user manual to selected required

alarm mode

No control

output

Wrong wiring

for control

output

Connect control output cable

correctly

Wrong

graduation

mark selected

Select correct graduation mark in

accordance with input signal

Wrong

connection for

sensors

Connect signal cable correctly

7

© 2015 Inkbird Inc. All rights reserved.

www.ink-bird.com, CS@ink-bird.com