Guidelines

Table Of Contents

- 1 Introduction

- 2 Packaging Technology

- 3 Thermal Specifications

- 4 Thermal Simulation

- 5 Thermal Metrology

- 6 Reference Thermal Solution

- A Thermal Solution Component Suppliers

- B Mechanical Drawings

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 23

Thermal Metrology

3. Measure the thermocouple resistance by holding both contacts on the connector on

one probe and the tip of thermocouple to the other probe of the DMM

(measurement should be about ~3.0 ohms for 36-gauge type T thermocouple).

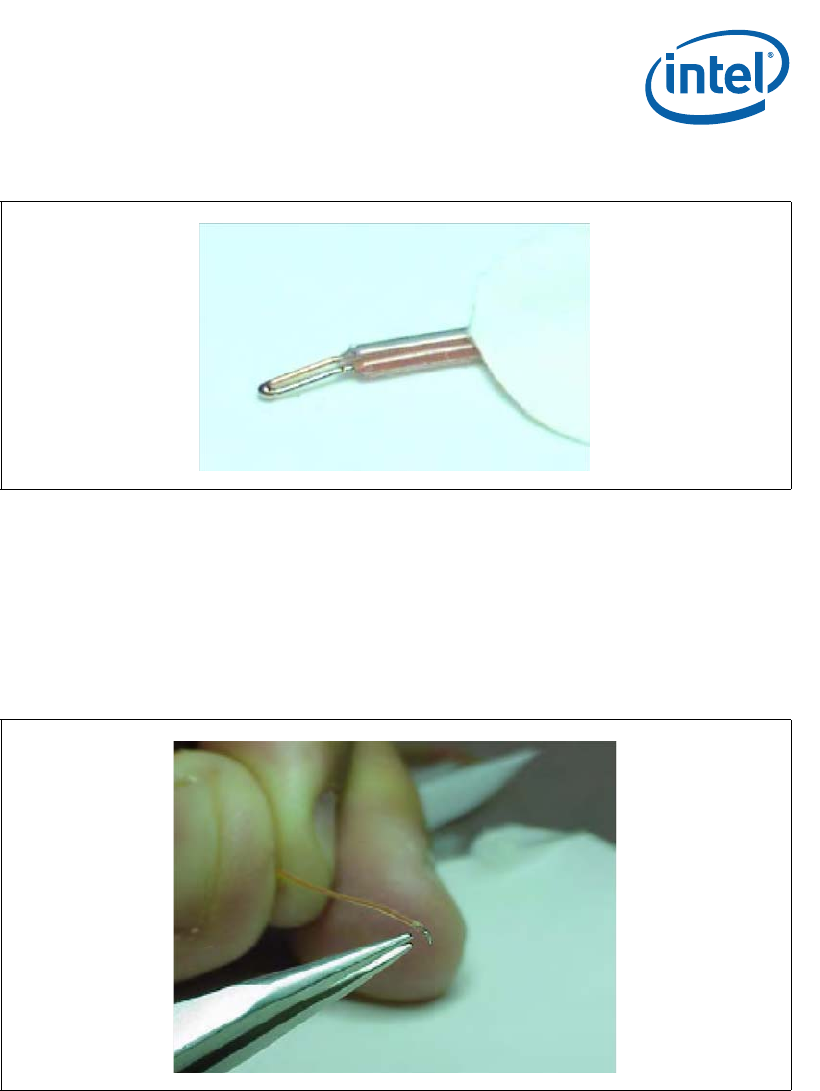

4. Straighten the wire for about 38 mm [1.5 inch] from the bead.

5. Using the microscope and tweezers, bend the tip of the thermocouple at

approximately 10 degree angle by about 0.8 mm [.030 inch] from the tip. Refer to

Figure 5-6.

5.1.4.2 Thermocouple attach to the IHS

6. Clean groove and IHS with Isopropyl Alcohol (IPA) and a lint free cloth removing all

residues prior to thermocouple attachment.

7. Place the Thermocouple wire inside the groove and let the exposed wire extend

slightly over the end of groove. Refer to Figure 5-7.

Figure 5-5. Inspection of Insulation on Thermocouple

Figure 5-6. Bending the Tip of the Thermocouple