Guidelines

Table Of Contents

- 1 Introduction

- 2 Packaging Technology

- 3 Thermal Specifications

- 4 Thermal Simulation

- 5 Thermal Metrology

- 6 Reference Thermal Solution

- A Thermal Solution Component Suppliers

- B Mechanical Drawings

Introduction

8 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

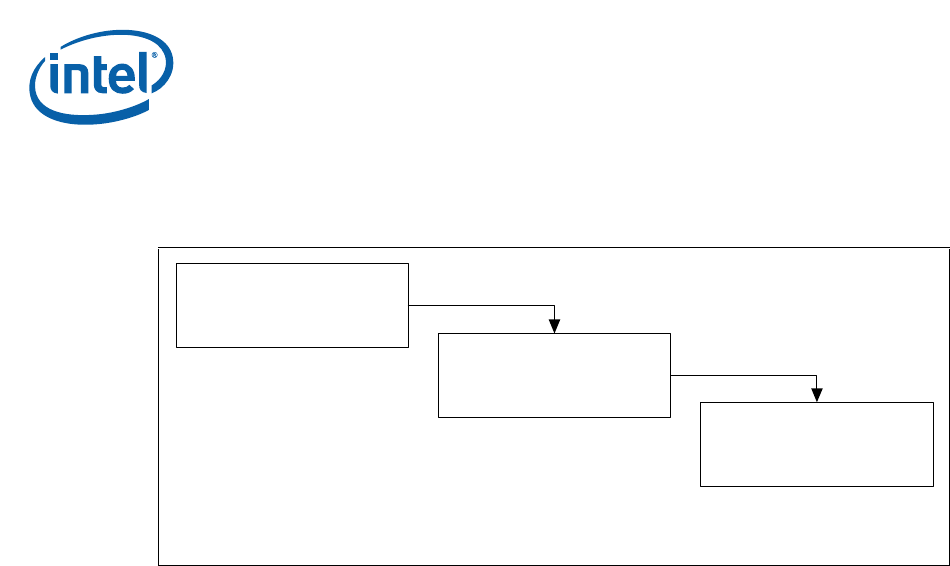

1.1 Design Flow

1.2 Definition of Terms

FC-BGA Flip Chip Ball Grid Array. A package type defined by a plastic

substrate where a die is mounted using an underfill C4

(Controlled Collapse Chip Connection) attach style. The primary

electrical interface is an array of solder balls attached to the

substrate opposite the die. Note that the device arrives at the

customer with solder balls attached.

BLT Bond line thickness. Final settled thickness of the thermal

interface material after installation of heatsink.

MCH Memory controller hub. The chipset component contains the

processor interface, the memory interface, the PCI Express*

interface and the DMI interface.

ICH I/O controller hub. The chipset component contains the MCH

interface, the SATA interface, the USB interface, the IDE

interface, the LPC interface, and so forth.

IHS Integrated Heat Spreader. A thermally conductive lid integrated

into the package to improve heat transfer to a thermal solution

through heat spreading.

T

case_max

Maximum die or IHS temperature allowed. This temperature is

measured at the geometric center of the top of the package die

or IHS.

T

case_min

Minimum die or IHS temperature allowed. This temperature is

measured at the geometric center of the top of the package die

or IHS.

TDP Thermal design power. Thermal solutions should be designed to

dissipate this target power level. TDP is not the maximum power

that the chipset can dissipate.

TIM Thermal Interface Material. Thermally conductive material

installed between two surfaces to improve heat transfer and

reduce interface contact resistance.

T

LA

The local ambient air temperature at the component of interest.

The local ambient temperature should be measured just

Figure 1-1. Thermal Design Process

y Thermal Model

y Thermal Model User's Guide

Step 1: Thermal

Simulation

y Thermal Reference

y Mechanical Reference

Step 2: Heatsink Selection

y Thermal Testing Software

y Software User's Guide

Step 3: Thermal Validation

001239