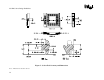

Intel Pentium 4 Processor 423 Pin Socket (PGA423) Design Guidelines

®

423 Pin Socket Design Guidelines

15

between the socket and the pin field. Actuation lever arm in locked

position must have the same profile as the socket cam and housing,

and must not interfere with the heatsink protrusion. The total

thickness of the cam house must reside within 0.350in from the

bottom surface of the socket.

3.3.3.4. Socket/Package pin field Movement

The socket will be built so that the package pin field displacement

will not exceed 0.060in during engagement and disengagement.

3.3.4. Contact Characteristics:

3.3.4.1. Number of contacts:

Total number of contacts: 423

3.3.4.2. Base Material:

High strength copper alloy.

3.3.4.3. Contact Area Plating:

15µin (min) gold plating over 50µin (min) nickel underplate in

critical contact areas (area on socket contacts where package pins will

mate), and plating must be able to pass the tests outlined in sections 4

and 5.

3.3.4.4. Solder tails plating:

100µin (min) tin lead over 50µin (min) nickel underplate.

3.3.4.5. Lubricants:

No lubricants shall be used on the socket contacts or in the cam.

3.3.5. Environmental Concerns Requirements:

Cadmium shall not be used in the painting or plating of the socket.

CFCs and HFCs shall not be used in manufacturing the socket.

3.4. Socket Manufacturability Requirements:

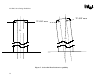

The socket must be a thru-hole socket design.

3.4.1. Overall Assembly Sequence:

Solder socket to motherboard