Intel Pentium 4 Processor 423 Pin Socket (PGA423) Design Guidelines

423 Pin Socket Design Guidelines

®

16

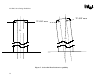

Insert processor into socket and lock it in using actuation lever.

Assemble heat sink onto the package.

3.4.2. Socket Engagement/Disengagement Force:

The force on the actuation lever arm must not exceed 10 lbf to engage or

disengage the package into the 423 Pin Socket. Movement of the cover is

limited to the plane parallel to the motherboard.

3.4.3. Visual Aids:

The socket top will have markings identifying open and closed positions for

the actuation lever arm.

3.4.4. Solderability Test:

Must pass 95% solder tail coverage per tail

3.5. Assembly Requirements to the Motherboard:

3.5.1. Pre- Solder Attachment:

A method of securing the socket to the motherboard is required to assist in

the manufacturing process. The securing method shall be consistent with

low-cost, high-volume printed circuit board assembly lines. It is not

acceptable to use a retention feature to achieve this goal. The socket pins

should be designed to be strong enough to secure the socket to the

motherboard during wave soldering.

3.5.2. Solder Tail Design and Alignment:

The socket solder tails must be designed and aligned such that the end of the

solder tails must enter a virtual-condition hole that is 0.029in ± 0.003in in

diameter.

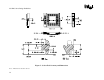

3.6. Socket Critical To Function (CTF) Dimensions:

The 423 Pin Socket shall accept an Intel

®

Pentium

®

4 processor package as shown in

Figure 1 and shall hold the package so that it is parallel with the motherboard. The

asymmetric pinout will help to properly align the socket to the motherboard and

prevent the socket from being assembled incorrectly to the motherboard.

Critical to function dimensions are identified in Figure 8. Each of the dimensions

must meet the requirements given in Table 2. These dimensions will be verified as

part of the qualification process. (See Table 3) Also, supplier will provide and

maintain Critical Process Parameters controlling these CTFs or will provide direct

measurements to meet ongoing quality requirements.