Workshop Manual

5–12 ENGINE ASSEMBLY III

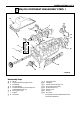

11. Piston and Connecting Rod

Position the piston ring gaps as shown in the illus-

tration.

1) Set the piston ring gaps as shown in the illustra-

tion.

2) Lubricate the piston, the piston rings, and the

connecting rod bearings with engine oil.

3) Position the piston front mark towards the front

of the engine.

1

4

3

2

4) Use the piston ring compressor to compress the

piston rings.

Piston Ring Compressor: 9-8522-1251-0

5) Use a hammer grip to push the piston in until it

makes contact with the crankpin.

At the same time, rotate the crankshaft until the

crankpin reaches its highest point.

Front

mark

(▲)

Piston ring compressor

6) Set the bearing cap cylinder number marks and

the connecting rod cylinder number marks.

The marks must be facing the exhaust manifold.

Cylinder

number

7) Lubricate the connecting rod cap bolt threads

and setting fases with Mos grease.

8) Use the angular tightening method to tighten

the connecting rod cap bolts to the specified

torque.

N·m (kgf·m/lb.ft)

12. Oil Pump and Coupling

1) Lubricate the oil pump with the specified grade

of engine oil.

2) Install the oil pump with the coupling.

3) Tighten the oil pump bolts to the specified

torque.

N·m (kgf·m/lb.ft)

1st step 2nd step

Connecting Rod Bolt Torque 39

60°–90°

and Angle (4/29)

Coupling

Oil Pump Bolt Torque 42–62 (4.3–6.4/31–46)