Workshop Manual

ENGINE ASSEMBLY III 5–15

Important Operations

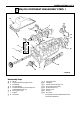

1. Flywheel

1) Lubricate the flywheel bolt threads.

2) Install the flywheel.

The crankshaft rear end dowel pin and the fly-

wheel dowel hole must be aligned.

3) Tighten the flywheel bolts to the specified

torque in the numerical order shown in the illus-

tration.

N·m (kgf·m/lb.ft)

Lubricate with

engine oil

1

6

5

2

4

3

2. Injection Pump and Injection Pump Gear Assembly

1) Install the injection pump bracket with the injec-

tion pump to the timing gear case.

Dowel the injection pump bracket with the tim-

ing gear case.

2) Tighten the injection pump bolts to the specified

torque.

N·m (kgf·m/lb.ft)

3) Align the injection pump gear "C" timing mark

with the idler gear "C" timing mark.

Injection pump gear

Idle gear

“B” mark

Camshaft

gear

Crankshaft gear

“A” mark

“C” mark

Air Compressor Installation (If so equipped)

1. Align the air compressor crankshaft spline end

marks and the injection pump drive gear shaft

female spline marks.

Flywheel

4B engine 142–172(14.5–17.5/105–127)

Bolt Torque

6B engine 197–240(20.1–24.5/145–177)

Injection Pump Bolt Torque 21 – 30 (2.1 – 3.1/15 – 22)