RECIRCULATING SOAK SINK CONVERSION INSTALLATION/OPERATION & TECHNICAL MANUAL FOR JACKSON MODEL: WHIRL WIZARD August 20, 2007 P/N 7610-011-70-65 (Revision D) www.jacksonmsc.

MANUFACTURERS WARRANTY ONE YEAR LIMITED PARTS & LABOR WARRANTY ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM DEFECTS IN MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION FOR A PERIOD OF (1) ONE YEAR FROM THE DATE OF PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM THE DATE OF SHIPMENT FROM THE FACTORY.

STOP! PARE! ARRET! CALL 1-888-800-5672 TO REGISTER THIS PRODUCT! FAILURE TO DO SO WILL VOID THE WARRANTY! LLAME AL 1-888-800-5672 PARA REGISTRAR ESTE PRODUCTO! AL NO HACERLO LA GARANTIA SERA ANULADA! S.V.P.

REVISION/ PAGE REVISION DATE D 08-20-2007 MADE APPLICABLE BY ECN MAW 7933 DETAILS Updated weldment numbers for cover and box weldments. Converted to centered layout.

NOMENCLATURE FOR THE MODELS COVERED IN THIS MANUAL AJ-54CE AJ = AJ Series of rack conveyors 54 = 54” wide machine from tub edge to tub edge 76 = 76” wide machine from tub edge to tub edge 90 = 90” wide machine from tub edge to tub edge CE = Electrically-heated, hot water sanitizing dishmachine CS = Steam-heated, hot water sanitizing dishmachine Jackson MSC LLC. provides technical support for all of the dishmachines detailed in this manual.

TABLE OF CONTENTS SECTION I. DESCRIPTION PAGE GENERAL Specifications Dimensions 2 3 INSTRUCTIONS SECTION Installation Instructions Operating Instructions 5 7 III. PREVENTATIVE MAINTENANCE 9 IV.

SECTION 1: SPECIFICATION INFORMATION 1

SECTION 1: SPECIFICATION INFORMATION WHIRL WIZARD This unit can be adapted to most standard three compartment sink to provide recirculated water to assist in the removal of soil from ware. The entire unit will fit within the frame work of standard sinks, so no additional floor space is required. For the 115 Volt unit, a one (1) horsepower motor and pump continually recirculates warm detergent laden water through a unique agitator mounted in the drain hole in the sink.

SECTION 1: SPECIFICATION INFORMATION DIMENSIONS Whirl Wizard Technical Manual 7610-011-70-65 Issued: 08-20-2007 Revised: N/A 3

SECTION 2: INSTALLATION & OPERATION INSTRUCTIONS 4

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS INSTALLATION INSTRUCTIONS VISUAL INSPECTION: Before installing the unit, check the container and machine for damage. A damaged container is an indicator that the machine may have been hadled roughly during shipping. If there is damage to both the container and the machine, do not throw away the container. The machine has been inspected at the factory and is expected to arrive to you in new, undamaged condition.

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS INSTALLATION INSTRUCTIONS (CONTINUED) ELECTRICAL POWER CONNECTION: 1. The Whirl Wizard requires a dedicated 20 amp, 115 volt single phase circuit. 2. A 20 amp NEMA 5-20R receptacle is required for the NEMA 5-20P cord set and plug shipped with the machine. CAUTION: A NEMA 5-20R RECEPTACLE IS REQUIRED. IF NOT AVAILABLE A QUALIFIED ELECTRICIAN SHOULD INSTALL THE CORRECT RECEPTACLE.

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS OPERATION INSTRUCTIONS OPERATION: 1. Install the directional manifold (item 1) into the main flow chamber (item 2). 2. Fill the sink with hot water. 3. Add the proper chemicals (non-foaming detergent) for soaking pots, pans and utensils. 4. Pre-scrap pots, pans and utensils of all large loose soil. NOTE: THE WHIRL WIZARD POT SINK IS NOT A GARBAGE DISPOSAL! IT IS INTENDED TO SOFTEN SOIL WHICH IS DIFFICULT TO REMOVE.

SECTION 3: PREVENTATIVE MAINTENANCE 8

SECTION 3: PREVENTATIVE MAINTENANCE PREVENTATIVE MAINTENANCE The dishmachines covered in this manual are designed to operate with a minimum of interaction with the operator. However, this does not mean that some items will not wear out in time. Jackson highly recommends that any maintenance and repairs not specifically discussed in this manual should be performed by QUALIFIED SERVICE PERSONNEL ONLY.

SECTION 4: PARTS SECTION 10

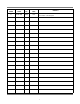

SECTION 4: PARTS SECTION INSTALLATION ASSEMBLY 1 2 8 3 4 14 15 5 6 7 13 11 10 9 12 15 ITEM QTY DESCRIPTION Mfg. No.

SECTION 4: PARTS SECTION MAIN ASSEMBLY 1 19 2 3 18 15 17 4 5 11 13 14 16 6 8, 9 7 14 12 10 TEM QTY DESCRIPTION Mfg. No.

SECTION 5: ELECTRICAL DIAGRAMS 13

SECTION 5: ELECTRICAL SCHEMATICS WHIRL WIZARD 115 VOLT - 60 HZ - SINGLE PHASE 9905-011-70-30 SEQUENCE OF OPERATION 1. After the sink is filled with water, power switch (S1) is placed in the “ON” position. 2. Motor contactor (R1) is energized. 3. Pump motor (M1) starts. 4. Heater element (H1) is energized. 5. Power light (E1) is energized. NOTE: THE HEATER ELEMENT CONTAINS AN INTERNALLY-MOUNTED THERMOSTAT TO REGULATE THE TEMPERATURE OF THE ELEMENT.

SECTION 5: ELECTRICAL SCHEMATICS WHIRL WIZARD 240 VOLT - 50/60 HZ - SINGLE PHASE 9905-002-33-80 SEQUENCE OF OPERATION 1. After the sink is filled with water, power switch (S1) is placed in the “ON” position. 2. Motor contactor (R1) is energized. 3. Pump motor (M1) starts. 4. Heater element (H1) is energized. 5. Power light (E1) is energized. NOTE: THE HEATER ELEMENT CONTAINS AN INTERNALLY-MOUNTED THERMOSTAT TO REGULATE THE TEMPERATURE OF THE ELEMENT.

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS 16

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS ALABAMA TO FLORIDA ALABAMA CALIFORNIA JONES-McLEOD APPLIANCE SVC 1616 7TH AVE. NORTH BIRMINGHAM, AL 35203 (205) 251-0159 800-821-1150 FAX: (205) 322-1440 service@jones-mcleod.com BARKERS FOOD MACHINERY SERVICES 5367 SECOND STREET IRWINDALE, CA 91706 (626) 960-9390 800-258-6999 FAX: (626) 337-4541 service@barkers.com JONES-McLEOD APPLIANCE SVC 854 LAKESIDE DRIVE MOBILE, AL 36693 (251) 666-7278 800-237-9859 FAX: (251) 661-0223 GCS SERVICE INC.

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS FLORIDA TO MARYLAND JONES-McLEOD APPLIANCE SVC 854 LAKESIDE DRIVE MOBILE, AL 36693 (251) 666-7278 800-237-9859 FAX: (251) 661-0223 service@jones-mcleod.com NASS PARTS AND SERVICE, INC. 1108 SOUTH WOODS AVENUE ORLANDO, FL 32805 (407) 425-2681 (800) 432-2795 (407) 425-3463 FAX NASS PARTS AND SERVICE, INC.

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS MARYLAND TO NEW YORK EMR SERVICE DIVISION 106 WILLIAMSPORT CIRCLE SALISBURY, MD 21804 (410) 543-8197 888-687-8080 FAX: (410) 548-4038 baltparts@emrco.com EMR SERVICE DIVISION 5316 Sunnyside Ave. Beltsville, MD 20715 (301) 931-7000 800-348-2365 FAX: (301) 931-3060 baltparts@emrco.com GCS SERVICE INC. SILVER SPRING, MD (301) 585-7550 (DC) (410) 792-0338 (BALT) (800) 638-7278 FAX: (301) 495-4410 MICHIGAN GCS SERVICE INC. ST.

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS NEW YORK TO PENNSYLVANIA B.E.S.T. INC. 3003 GENESEE STREET BUFFALO, NY 14225 (716) 893-6464 800-338-5011 FAX: (716) 893-6466 bestserv@aol.com DUFFY'S EQUIPMENT SVC. 3138 ONEIDA STREET SAUQUOIT, NY 13456 (315) 737-9401 800-443-8339 FAX: (315) 737-7132 duffyequip@aol.com NORTHERN PARTS & SVC. 21 NORTHERN AVENUE PLATTSBURGH, NY 12903 (518) 563-3200 800-634-5005 FAX: (800) 782-5424 info@northernparts.com GCS SERVICE INC.

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS RHODE ISLAND TO WISCONSIN RHODE ISLAND GCS SERVICE INC. EAST PROVIDENCE, RI (401) 434-6803 800-462-6012 FAX: (401) 438-9400 SUPERIOR KITCHEN SERVICE INC. 669 ELMWOOD AVENUE PROVIDENCE, RI 02907 (888) 590-1899 (401) 781-1996 FAX WHALEY FOODSERVICE REPAIRS 4740-A FRANCHISE STREET N. CHARLESTON, SC 29418 (843) 760-2110 FAX: (843) 760-2255 info@whaleyfoodservice.com SOUTH DAKOTA GCS SERVICE INC.

SECTION 6: JACKSON MAINTENANCE & REPAIR CENTERS WISCONSIN TO WYOMING/INTERNATIONAL GENERAL PARTS, INC. W223 N735 SARATOGA DRIVE WAUKESHA, WI 53186 (262) 650-6666 (800) 279-9946 (262) 650-6660 FAX WYOMING HAWKINS COMMERCIAL APPLIANCE SERVICE 3000 S. WYANDOT ST. ENGLEWOOD, CO 80110 (303) 781-5548 (800) 624-2117 FAX: (303) 761-5561 johns@hawkinscommercial.com METRO APPLIANCE SERVICE 1640 S BROADWAY DENVER, CO 80210 (303) 778-1126 800-525-3532 FAX: (303) 778-0268 metroappls@aol.