Service Manual Instruction Manual

Table Of Contents

- Section A. Introduction - Maintenance Safety Precautions

- Section 1. Specifications

- Section 2. General

- Section 3. Chassis & Turntable

- 3.1 Tires And Wheels

- 3.2 Torque Hub

- Oil Information

- Roll and Leak Testing

- Tightening and Torquing Bolts

- Main Disassembly

- Output Carrier Disassembly

- Input Carrier Disassembly

- Hub-Spindle Disassembly

- Spindle-Brake Disassembly

- Cover Disassembly

- Cover Assembly

- Input Carrier Sub-Assembly

- Output Planet Gear Sub-Assembly

- Spindle - Brake Sub-Assembly

- Hub-Spindle Sub-Assembly

- Cover Sub-Assembly

- Main Assembly

- Integral Brake Check

- 3.3 Free Wheeling Option

- 3.4 Drive Motor

- 3.5 Oscillating Axle Bleeding Procedure and Lockout Test

- 3.6 Steer Adjustments

- 3.7 Swing Drive

- 3.8 Swing Bearing

- 3.9 Swing Brake - Mico

- 3.10 Rotary Coupling

- 3.11 Generator

- 3.12 Deutz D2.9 L4 Engine

- 3.13 Deutz D2011 Engine

- 3.14 Spark Arrester Cleaning Instructions

- 3.15 Glow Plugs

- 3.16 Deutz EMR 2

- 3.17 Bio Fuel in Deutz Engines

- 3.18 GM Engine General Maintenance

- 3.19 GM Engine Dual Fuel System

- Fuel Filter

- Direct Electronic Pressure Regulator (DEPR)

- Air Fuel Mixer

- Electronic Throttle Control (ETC)

- Electric Lock Off

- Engine Control Module (ECM)

- Heated Exhaust Gas Oxygen Sensor

- Gasoline Multi Point Fuel Injection System (MPFI)

- Gasoline Fuel Pump

- Gasoline Pressure And Temperature Sensor Manifold

- Fuel Filter

- Fuel Injector Rail

- Fuel Injector

- 3.20 GM Engine Fuel System Repair

- Propane Fuel System Pressure Relief

- Propane Fuel System Leak Test

- Propane Fuel Filter Replacement

- Direct Electronic Pressure Regulator (DEPR) Maintenance And Inspection

- Check/Drain Oil Build-Up In 2-Stage Vaporizer

- Air Fuel Mixer/Throttle Control Device Maintenance And Inspection

- Exhaust System And Catalytic Converter Inspection And Maintenance

- Temperature Manifold Absolute Pressure (TMAP) Sensor

- Throttle Body (ETC) Replacement

- Mixer Replacement

- Electronic Pressure Regulator (EPR) Replacement

- Regulator Replacement

- Coolant Hose Replacement

- Vapor Hose Replacement

- Engine Control Module Replacement

- Heated Exhaust Gas Oxygen Sensor Replacement

- 3.21 GM Engine LPG Fuel System Diagnosis

- Section 4. Boom & Platform

- Section 5. Hydraulics

- 5.1 O-Ring Lubrication

- 5.2 Cylinders - Theory of Operation

- 5.3 Cylinder Checking Procedure

- 5.4 Cylinder Removal and Installation

- Cylinder Locations

- Main Boom Telescope Cylinder Removal

- Main Boom Telescope Cylinder Installation

- Main Boom Lift Cylinder Removal

- Main Boom Lift Cylinder Installation

- Upright Level Cylinder Removal

- Upright Level Cylinder Installation

- Tower Boom Lift Cylinder Removal

- Tower Lift Cylinder Installation

- Tower Telescope Cylinder Removal

- Tower Telescope Cylinder Installation

- 5.5 Hydraulic Cylinder repair

- Tower Boom Lift Cylinder

- Cleaning and Inspection

- Assembly

- Upright Level Cylinder

- Cleaning and Inspection

- Assembly

- Master Cylinder

- Cleaning and Inspection

- Assembly

- Main Boom Lift Cylinder

- Cleaning and Inspection

- Assembly

- Main Boom Telescope Cylinder

- Cleaning and Inspection

- Assembly

- Tower Boom Telescope Cylinder

- Cleaning and Inspection

- Assembly

- Platform Level (Slave) Cylinder

- Cleaning and Inspection

- Assembly

- Jib Lift Cylinder (AJ Only)

- Cleaning and Inspection

- Assembly

- Steer Cylinder

- Cleaning and Inspection

- Assembly

- Axle Lockout Cylinder

- 5.6 Hydraulic Pump (Gear)

- 5.7 Variable Pump

- 5.8 Hydraulic Component Start-Up

- 5.9 Pressure Setting Procedures

- Section 6. JLG Control System

- Section 7. Basic Electrical Information & Schematics

SECTION 3 - CHASSIS & TURNTABLE

3-92 – JLG Lift – 3121616

Table 3-10. LP Fuel System Diagnosis

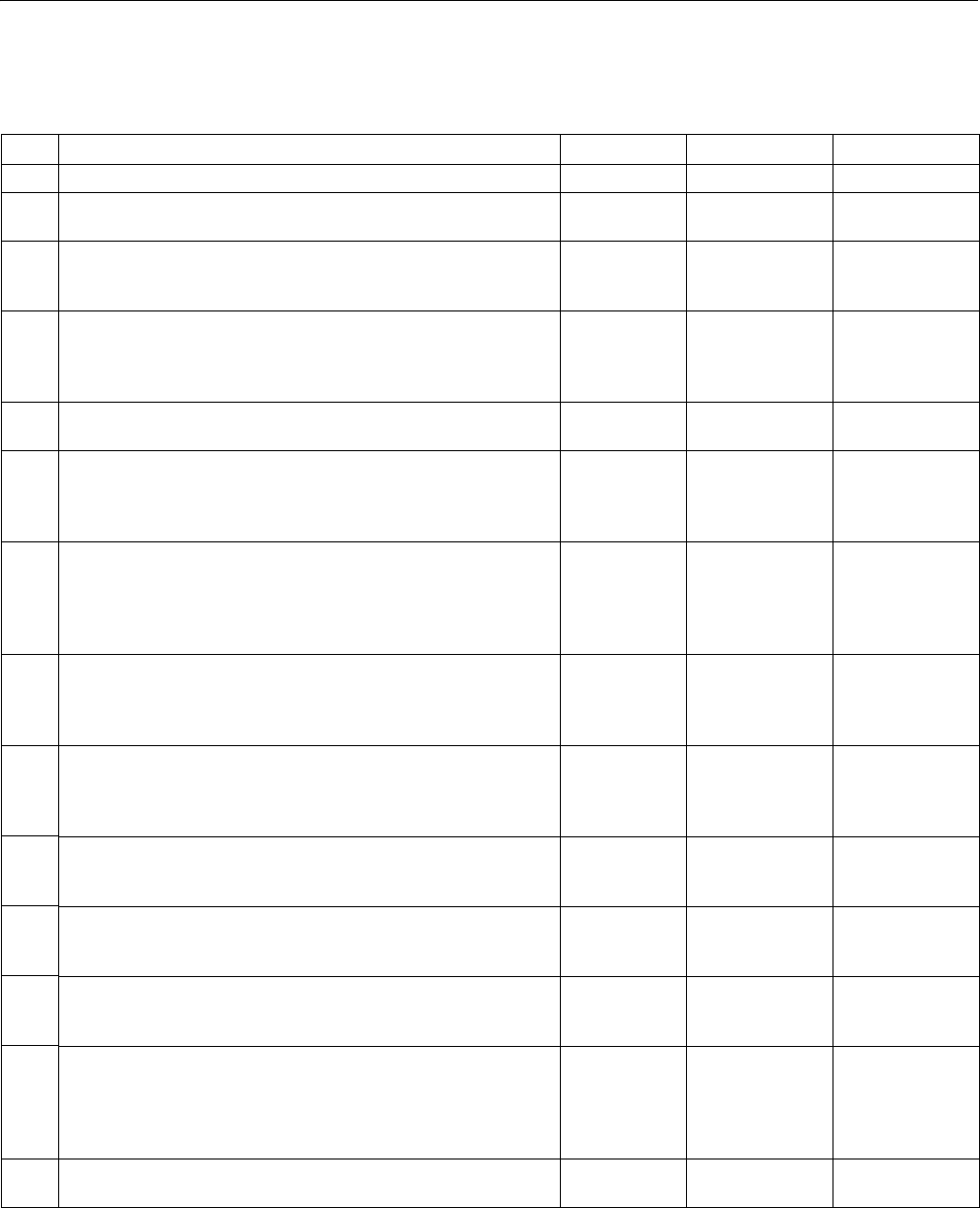

STEP ACTION VALUE(S) YES NO

1 Were you referred to this procedure by a DTC d ia gn os ti c c har t ? - - Go to Step 3 G o t o S te p 2

2 Perform the On Board Diagnostic (OBD) System Check.

Are any DTCs present in the ECM?

- - Go to the

applicable DTC Table

Go to St ep 3

3 Verify that the LPG fuel tank has a minimum of 1/4 tank of fuel, that the manual valve is open

and the tank quick connect is fully engaged

Does the vehicle have fuel?

- - Go to Step 4 - -

4 1. Connect a water column gauge or a manometer to the secondary test port of the low pressure

regulator (LPR).

2. Start the engine and allow it to reach operating temperature.

Does the engine start and run?

- - Go to Step 5 Go to Step 8

5 With the engine idling, observe the pressure reading for the LPR secondary pressure.

Does the fuel pressure fluctuate rhythmically OUTSIDE the specified range?

-1.0" to

-2.0" w.c

G o to St ep 25 Go to St ep 6

6 1. Disconnect the EPR electrical connectors. NOTE: This action will cause a DTC to be set by the

ECM

2. With the engine idling observe the pressure reading on the secondary test port.

Is the fuel pressure WITHIN the specified range?

-1.0" to

-2.0" w.c

Go to Fuel Control System

Diagnosis

Go to St ep 7

7 1. Inspect the air intake stream between the mixer assembly and the throttle body for leaks.

2. Inspect the fuel hose connection between the LPR and mixer assembly for damage or leak-

age.

3. Inspect any vacuum hoses for leaks

Was a problem found and corrected?

- - Go t o S te p 2 6 G o t o S tep 22

8 1. Connect a water column gauge or a manometer to the secondary test port of the low pressure

regulator (LPR).

2. Crank the engine and observe the pressure reading for the LPR secondary pressure.

D oe s t he fu el pre ss ur e i nd ic at e a va cu um is pre se nt ?

- - Go t o S te p 1 2 G o t o S tep 9

9 1. Remove Air induction hose to the mixer

2. Observe the air valve for movement while the engine is cranking. Note: Movement of the air

valve will be minimal at cranking speeds.

D oe s t he ai r va lv e m ove w hen th e eng ine is c ra nk ed ?

- - Go t o S te p 1 1 G o t o S tep 10

10 1. Inspect the air intake stream to the mixer assembly and the throttle body for vacuum leaks.

2. Inspect the vacuum hoses from the mixer for proper connection and condition.

Was a problem found and repaired?

- - Go t o S te p 2 6 G o t o S tep 24

11 Inspect the fuel hose connection between the LPR and the mixer assembly for damage or leak-

age.

Was a problem found and repaired?

- - Go t o S te p 2 6 G o t o S tep 12

12 1. Connect a 0-10 psi gauge to the primary test port of the low pressure regulator (LPR).

2. Crank the engine and observe the pressure reading for the LPR primary pressure.

Is the fuel pressure ABOVE the specified value?

1- 3 PS I G o t o S te p 2 2 G o t o S tep 13

13 1. Turn OFF the ignition.

2. Disconnect the LPL connector.

3. Install a test light between the pins of the LPL connector.

4. Crank the engine. The test light should illuminate.

Does the test light illuminate?

- - Go t o S te p 1 4 G o t o S tep 16

14 Using a DVOM, check the resistance of the low pressure lock-off (LPL).

Is the resistance within the specified range?

12W - 16W G o to St ep 15 Go to St ep 23