Installation Guide

33

6. Using two wrenches, separate the ground-joint union

in the gas supply piping at the furnace.

7. Remove the piping between the Gas Valve and the

ground-joint union. (If applicable).

8. Remove all screws securing the Manifold Assembly to

the Burner Box.

9. Carefully remove the burner assembly from the furnace.

DO NOT DAMAGE THE IGNITER WHILE REMOVING

THE BURNER ASSEMBLY.

10.Inspect the burners for accumulated dust or debris.

If necessary carefully clean them with a soft wire

brush and a vacuum cleaner. DO NOT DAMAGE THE

IGNITER WHILE CLEANING THE BURNER.

11.Replace all the parts in reverse order from which they

were removed.

12.Follow the lighting instructions found on the furnace

door to return the furnace to operation. Verify proper

operation after servicing.

6ENT3YSTEM Check the inlet pipe (if applicable) and

outlet pipe to ensure they are not blocked by debris. Any

damaged section of vent pipe must be replaced, and

any obstruction or blockage must be removed prior to

operating the furnace.

(EAT%XCHANGER"URNER-AINTENANCE The furnace

should operate for many years without soot buildup in the

flue passageways, however, the flue, vent system, and

burners should be inspected and cleaned (if required) by

a qualified service technician annually to ensure continued

safe operation. Pay attention to any deterioration from

corrosion or other sources.

WARNING:

(OLESINTHEVENTPIPEORHEATEXCHANGERCAN

CAUSECOMBUSTIONPRODUCTSTOENTERTHEHOME

2EPLACETHEVENTPIPEORHEATEXCHANGERIFLEAKS

ARE FOUND &AILURE TO PREVENT THE CIRCULATION

OFCOMBUSTIONPRODUCTSINTOTHELIVINGSPACE

CAN CREATE POTENTIALLY HAZARDOUS CONDITIONS

INCLUDING CARBON MONOXIDE POISONING THAT

COULDRESULTINPERSONALINJURYORDEATH

,UBRICATION The bearings in the blower motor and

inducer blower used in these furnaces are pre-lubricated

and sealed by the manufacturer. No further oiling of the

bearings is required for the life of the motor.

FIGURES & TABLES

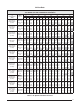

A

34 1/2

17 1/4

10 1/4

22 1/4

22 1/2

2 3/4

22 1/2

22 1/4

25

17 7/16

29 1/2

17 1/4

22 1/2

25 3/8

Gas

(Ø 1 5/8)

T-stat

(Ø 7/8)

18 1/2

Front

Brace

LEFT SIDE

RIGHT SIDE

Electric

(Ø 7/8)

25 1/2

22 1/2

Gas (Ø 1 5/8)

Vent pipe

(Ø 3”)

Cond. (Ø 1 1/16)

B

19

FLANGES

TOP VIEW

C

BOTTOM VIEW

Electric

(Ø 7/8)

Vent pipe

(Ø 3”)

Cond. (Ø 1 1/16)

FRONT VIEW

28

3

Flue

Combustion

Air

7 1/2

*SL & *SM Downflow Furnaces

-ODELS $IM! $IM" $IM#

054D-24B

17 1/2 15 7/8 16 1/8

072D-24B

072D-35C

21 19 3/8 19 5/8

090D-35C

118D-45D

24 1/2 22 7/8 23 1/8

120D-45D

NOTE: Dimensions shown in inches.

Figure 31. 3,3-#ABINET$IMENSIONS