Installation Guide

31

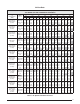

OPERATING SEQUENCE

The operating sequences for the heating, cooling, and

fan modes are described below. Refer to the field and

furnace wiring diagrams: Figure 27 (page 28), Figure

28 (page 29) and Figure 33 (page 39).

(EATING#YCLE

1. The thermostat calls for heat by energizing the W

terminal with 24VAC.

2. The control verifies the pressure switch is open.

3. If the pressure switch is open, the control energizes the

inducer and waits for the pressure switch to close. The

pressure switch must close within 10 seconds.

4. The control runs the inducer for a 30 second pre-purge.

5. The control energizes the Hot Surface Igniter (HSI)

output for the appropriate warm-up time limit.

6. The control energizes the main gas valve for 3 seconds.

7. If the flame proved and ignites the gas, the control de-

energizes the HSI. The gas valve and inducer remains

energized. The control goes to blower on delay.

8. If flame is present, the control energizes the blower on

the selected HEAT speed 30 seconds after the gas valve

opened. The gas valve and inducer remain energized.

9. When the thermostat demand for heat is satisfied, the

control de-energizes the gas valve. The Inducer output

remains on for a 30 second post-purge period.

10.Blower off timing begins when the thermostat is

satisfied. The control will operate at the selected HEAT

speed of 60, 90, 120, or 180 seconds. If the blower off

delay jumper is not present, the fan should still operate

for 120 seconds at the selected HEAT speed. The

Indoor blower motor is de-energized after a blower off

delay as selected by the movable jumper.

#OOLING#YCLE

1. The thermostat calls for cooling by energizing the Y

terminal with 24VAC.

2. The control energizes the blower in cooling speed and

sends 24VAC to the contactor in the condensing unit

3. When the thermostat removes the call for cooling, the

contactor in the outdoor condensing unit is de-energized

and the control continues to run the fan for a period of

60 seconds.

Fan Mode

s 7HEN THE THERMOSTAT ENERGIZES THE G terminal for

continuous fan (without calling for heat or cooling), the

screw all the way out from the valve, turn the screw

slowly.

d.) Replace and tighten the regulator capscrew over

the adjustment screw.

6ERIFYING!DJUSTING4EMPERATURE2ISE

After installation of the furnace, confirm the temperature

rise of the furnace is within the limits specified on the rating

plate. Any temperature rise outside the specified limits

could result in premature failure of the heat exchanger.

1. Place thermometers in the return and supply air stream

as close to the furnace as possible. The thermometer on

the supply air side must be shielded from direct radiation

from the heat exchanger to avoid false readings.

2. Adjust all registers and duct dampers to the desired

position and run the furnace for 10 to 15 minutes before

taking any temperature readings. The temperature rise

is the difference between the supply and return air

temperatures.

For typical duct systems, the temperature rise will fall

within the limits specified on the rating plate with the

blower speed at the factory recommended setting. If the

measured temperature rise is outside the specified limits,

it may be necessary to change the speed of the blower.

NOTE: Lowering the blower speed will increase the

temperature rise and a higher blower speed will decrease

the temperature rise.

The furnace is equipped with a multi-speed motor. Heating

and cooling speed selection is made by moving the switch

on the integrated control located in the furnace.

6ERIFYING"URNER/PERATION

CAUTION:

4HEDOOROVERTHEBURNERSMAYONLYBEOPEN

FORINSPECTIONPURPOSESONLY4HEDOORMUSTBE

INSTALLEDDURINGUNATTENDEDOPERATION

1. Remove the burner compartment door.

2. Set the thermostat above room temperature and observe

the ignition sequence. NOTE: The burner flame should

carry over immediately between all burners without

lifting off, curling, or floating. The flames should be blue,

without yellow tips.

3. After validating the flame, change thermostat setting to

below room temperature.

4. Verify the burner flame is completely extinguished.

5. Replace the burner compartment door.

6ERIFYING/PERATIONOFTHE3UPPLY!IR,IMIT

3WITCH

NOTE: A properly functioning limit switch should turn off

the gas valve when the return is blocked (time depends

on how well the return air is blocked). The circulating air

and combustion blowers should continue to run when the

limit switch opens.

1. Verify the blower door is securely mounted in place and

that there is power to the furnace.

2. Block the return airflow to the furnace by installing a

close-off plate in place of or upstream of the filter(s).

3. Set the thermostat above room temperature and observe

the Operating Sequence.

4. Remove the close-off immediately after the limit switch

opens. If the furnace continues to operate with no return

air, set the thermostat below room temperature, shut

off power to the furnace, and replace the limit switch.